Over the coming weeks, our Marine Robotics and Offshore Renewable Energy Business Development Managers Aidan Thorn and Mike Ellis will be delivering a series of blogs and a white paper on the use of marine robotics for planning, monitoring, communications and positioning in offshore wind farms.

To begin the series, we look at how robotics are currently used in the marine environment and consider how they might be utilised in future offshore wind projects.

Floating offshore wind farms, maintained by robots – pipedream or possibility?

It’s certainly possible, but how close are we to realising it? With wind overtaking gas as the primary source of UK electricity for the first time in May 2023 (figures from Imperial College London), and with most of that generated offshore, the demand for cost effective renewable energy in the UK is set to increase further.

It’s a global trend. The Global Wind Energy Council (GWEC) Global Wind Report 2023 predicts that 2023 will be the first year to see more than 100 GW of new wind energy capacity added globally. Whilst the majority of this is onshore production, the offshore share of the market is steadily increasing.

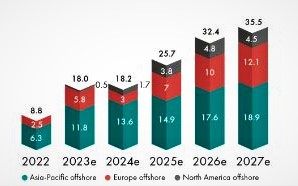

Predicted Global Offshore Wind Installations (GW) 2022-2027 (GWEC Global Wind Report 2023)

Predicted Global Offshore Wind Installations (GW) 2022-2027 (GWEC Global Wind Report 2023)

According to GWEC, the top five markets for new wind installations in 2022 were China, the USA, Brazil, Germany and Sweden – accounting for 71% of global installations of both on and offshore wind farms. When it comes to offshore energy production, 99% of the global offshore wind installations are in Europe and the Asia Pacific region. With land often at a premium, surely the rest of the world will follow suit and look offshore for their energy, but at what cost?

According to the Offshore Renewable Energy (ORE) Catapult, about 40% of a fixed offshore wind farm’s cost is underwater. As the industry looks towards floating wind farms to meet demand, it’s a safe assumption these costs will rise when we consider that in the oil and gas industry typically 70% of the installation and maintenance costs are spent on the underwater floating assets.

“We need to start thinking beyond infrastructure in its current form to one which enables cost effective, remote and continuous inspection, repair and maintenance (IRM) strategy through the use of marine robotics.” Mike Ellis, Business Development Manager – Offshore Renewable Energy, Sonardyne

Surveying and constructing

With escalating operational costs and growing concerns over the environmental impact the default of using large vessels for site surveys is beginning to change, especially in the consenting phase of offshore wind farm construction. By using marine robotics for seabed surveys, we can build in lower cost, reduced carbon and increased reliability. If we implement an infrastructure to support effective monitoring and marine robotics at the start of a wind farm lifecycle before operations begin, operators can realise project savings much earlier.

“Over the last decades, we’ve seen some examples of poor geophysical and geotechnical data acquisition. As wind farms go deeper for floating platforms, deep-water autonomous underwater vehicles (AUV’s) that fly at low altitude for high-level resolution bathymetric and geophysical data should be considered. For example, the Morro Bay floating wind farm site in California will be between 1000 m and 1250 m deep, a surface vessel with high-res capabilities to cover a site of this acreage would prove vastly more expensive compared to mission planning an AUV from a small local port.” Mike Ellis, Business Development Manager – Offshore Renewable Energy, Sonardyne

Several developers are already using Uncrewed Surface Vessels (USVs) with our products for site characterisation and bathymetric surveys. Here, USVs can harvest current, wave and other scientific measurements from our Origin Acoustic Doppler Current Profilers (ADCPs) using one of the Ultra Short Base Line (USBL) systems or modems as a communication gateway. At the same time, the USBL system can also be used for positioning any towed equipment from the vehicle such as a magnetometer or side-scan sonar during a hydrographic survey.

“We’ve already been working with USV developers to show how marine robotics can be used for rapid data harvesting. For example, HydroSurv’s REAV-40 USV was fitted with our Mini-Ranger 2 USBL system to demonstrate rapid environmental collection to a group of stakeholders in the Valorous floating offshore wind project. Data harvesting while conducting a survey is a great way to save money and add to the information value chain.” Aidan Thorn, Business Development Manager – Marine Robotics, Sonardyne

During the construction phase of an offshore wind farm, it is important to ensure the area is clear of any hazards before running cables and piling in monopiles, so Remotely Operated Vehicles (ROVs) will typically conduct surveys for Unexploded Ordnance (UXO). However, we now have more conversations about USVs with onboard ROVs or using towed platforms to carry out this operation.

It opens up a multitude of additional operations that could also include identifying and removing classified UXOs using our wireless Initiation Transponder 6 (IT6) (see picture and link below), piling inspection support using imaging sensors, and cable depth of burial measurement.

A small inspection class, ROV attaching the wireless IT6 to a UXO

As wind farms go over the horizon, so will the robotics

We’re already seeing an increasing number of high-endurance, long-distance AUVs, like Cellula Robotics’ Solus LR AUV and the National Oceanography Centre’s Autosub Long Range being used in the field.

These are progressively capable of lengthy inspection missions and, used in conjunction with the relevant products, are ideal for monitoring and data harvesting from sensors deployed in and around offshore wind farms. This will become increasingly useful for geophysical site surveys conducted as we see developments in deeper waters, further offshore.

Most critically however, these over-the-horizon robotics rely on accurate and reliable navigation. Using a hybrid Inertial Navigation System (INS) from our SPRINT-Nav family provides a stand-alone platform with both altitude and heading, plus continuous navigation without a GPS update. This creates a reliable secondary system in the event of a lost satellite position.

Offshore robotics 24/7?

As these vehicles become increasingly viable, so does the prospect of having field-resident AUVs. Field resident robotics can carry out routine and on-demand surveys and inspections within a wind farm without the constant need to return to a mother ship. This would allow for more efficient and cost-effective operations while also reducing the risk of human error. AUVs can be equipped with advanced sensors and cameras to collect data and monitor wind farms in real-time.

We’re already seeing several companies delivering subsea vehicle docking, for example, Modus with their Saab Sabertooth AUV’s and Oceaneering’s Freedom vehicle. These agile (six degrees of freedom) vehicles are also very well suited to floating wind farm IRM operations, as the complexity of navigating between hundreds of moorings and dynamic cables increases significantly.

“I believe having vehicles that can sense and pivot around infrastructure without an umbilical will be essential to the adoption of these systems. This technology will likely be implemented first from vessels but has a long-term future in residence. The potential benefits of this technology are immense, and it could revolutionise the way we manage and maintain wind farms in the future.” Aidan Thorn, Business Development Manager – Marine Robotics, Sonardyne

Using acoustic communications, like the USBL positioning system with high bandwidth telemetry capability, via subsea docking stations, these vehicles can be positioned and data can be offloaded. They can even download new mission plans without surfacing. But let’s discuss this further in our next blog post.