Over the horizon robotic data harvest aids Shell's net zero ambition

Sonardyne, working with XOCEAN’s Uncrewed Surface Vehicles (USV), deliver a lower cost, lower risk and lower carbon, remote acoustic data harvesting service to Shell from their Ormen Lange gas field in the Norwegian Sea.

Shell’s Ormen Lange gas field is a deep-sea site 120 km / 75 miles off the coast of Norway. As Norway’s second largest gas producer, it plays a key role delivering stable gas supplies to Europe. Built on the site close to Storegga, a major landslide which occurred some 8000 years ago, about 5 million tonnes of rock was used to prepare the seabed for subsea equipment back in 2005. The field has been operational since 2007. Ormen Lange is distinctive in that it doesn’t have conventional surface operation platforms.

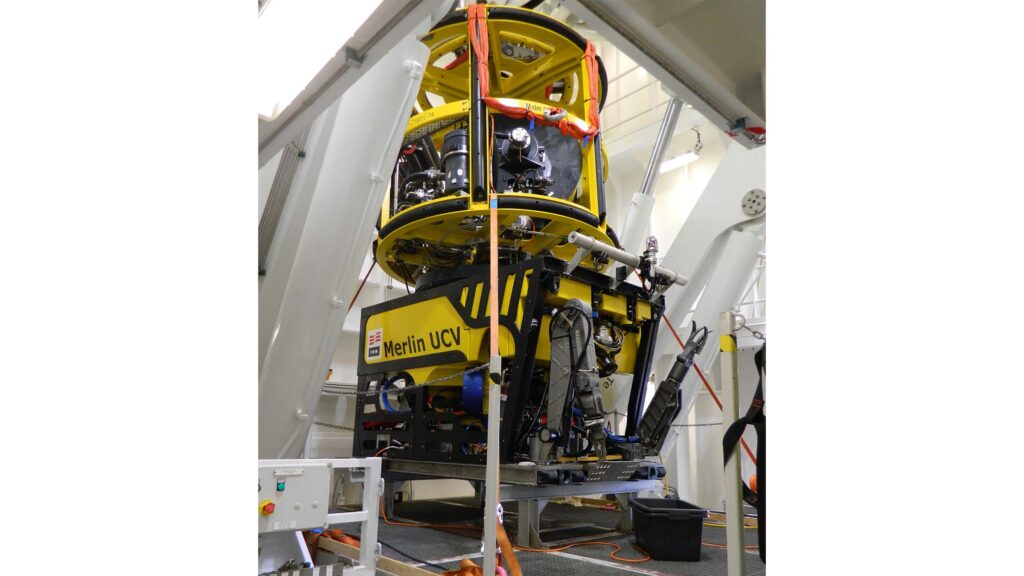

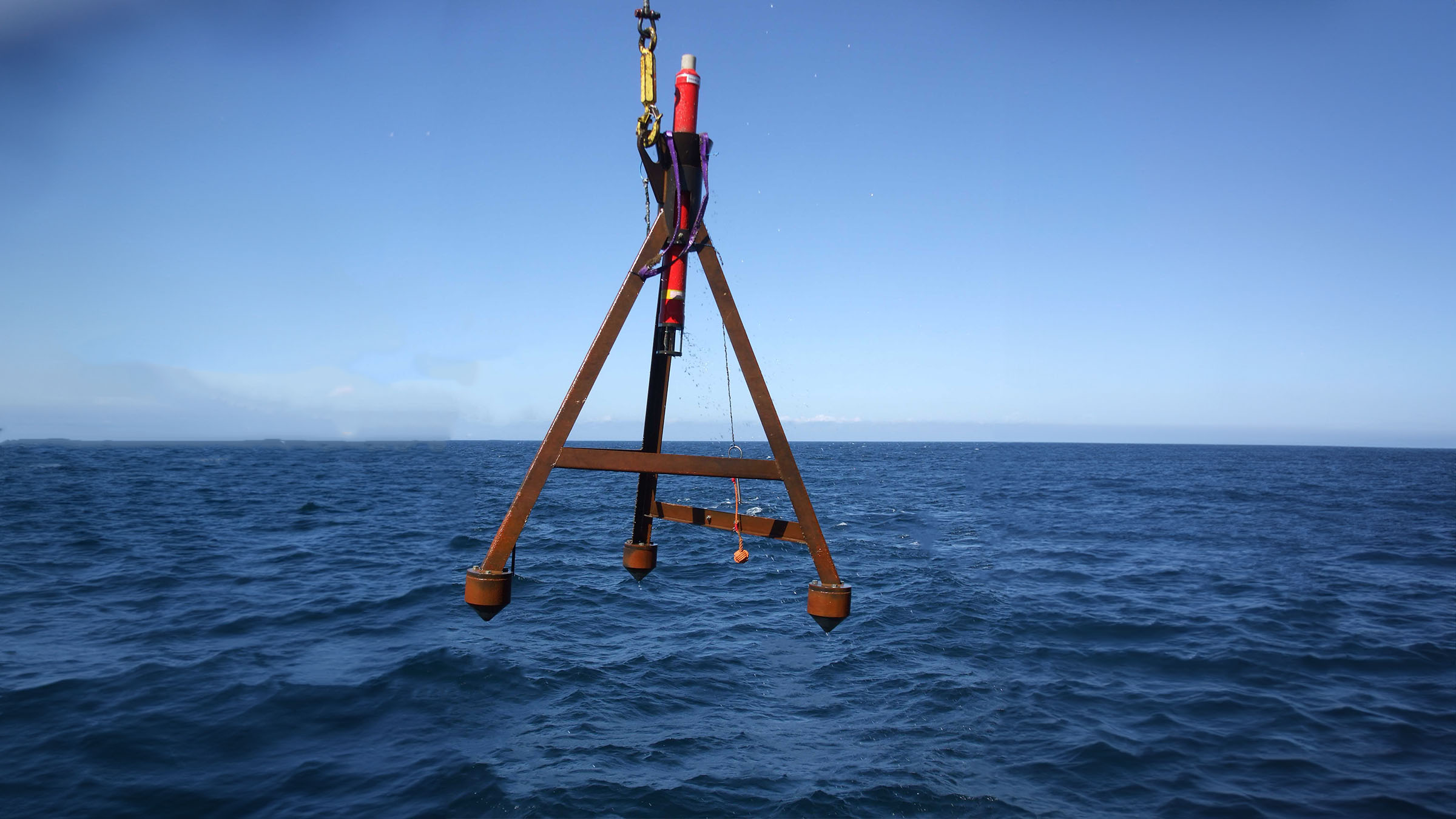

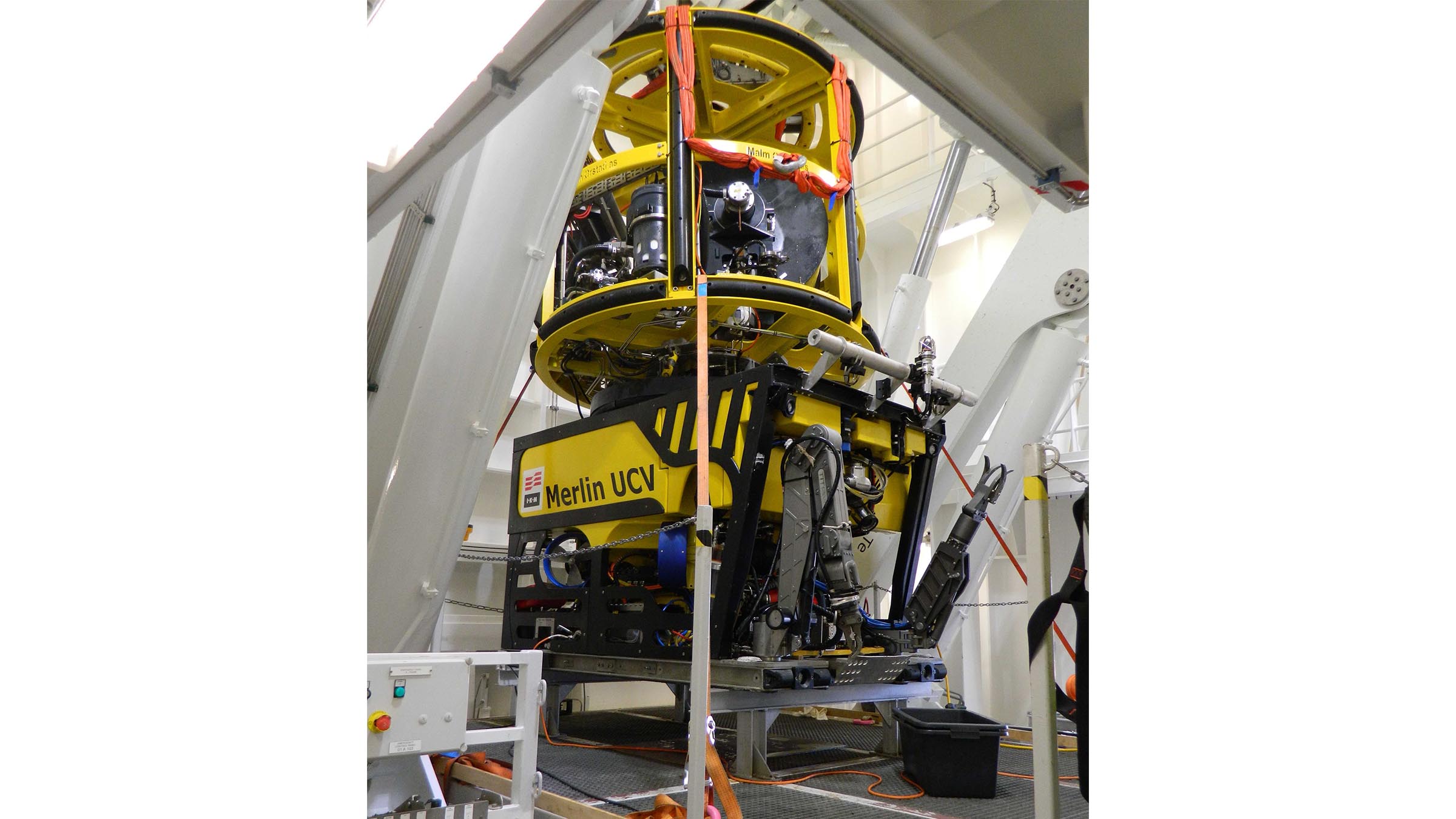

Close monitoring of any seabed movement is key to prevent any potential impact to the pipe system. Monitoring of the ocean floor around the well heads is conducted by seabed sensors. The first monitoring array at the site saw 203 Acoustic Monitoring Transponders (AMTs) installed in 2011. These sensors enabled monitoring of changes in pressure and tilt to provide an understanding of seabed movement.

This array was recovered in 2016 due to battery limitations and uncertainty in drift. Today the monitoring is undertaken by an array of 75 Sonardyne seabed Pressure Monitoring Transponders (PMTs). Shell took the decision to install 30 PMTs in 2019 with a further 45 installed in 2020.

The challenge

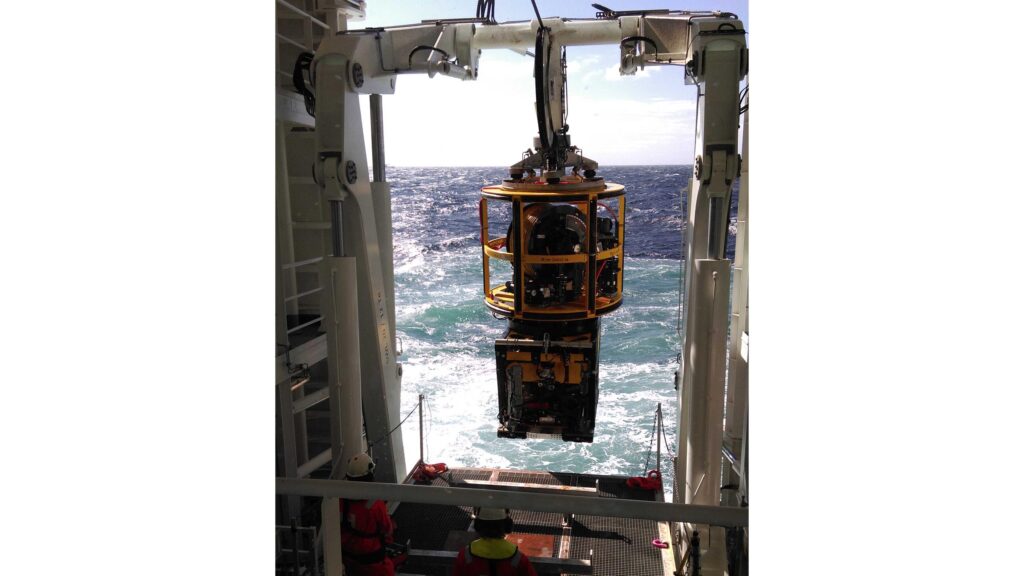

Without surface platforms, acoustic data from the subsea sensors had to be harvested by crewed vessels in the early years of the field’s operation. This was costly, carbon heavy and posed a risk to personnel in often challenging sea conditions.

With a company ‘Powering Progress’ strategy to achieve net-zero emissions by 2050, Shell was looking for an alternative data harvest method that would reduce cost and risk as well as its carbon footprint.

The solution

Marine robotic platforms provide the opportunity to remove carbon and personnel risk. Working with the customer and XOCEAN as a sub-contractor we developed a solution that would save time, costs. and carbon, while also eliminating the human risk element, using a USV to conduct the data harvest.

The proposal was to use our HPT 3000 transceiver mounted to an XOCEAN USV to remotely harvest data from the 75 seabed PMTs. The HPT 3000 is perfect in terms of size, weight and power for deployment from a USV and can communicate with seabed transponders at depths up to 995 m (or 4000 m with an extended range version).

XOCEAN USVs are perfect for the data harvesting mission at Ormen Lange. They enable full over-the-horizon 24/7 operations. This means that operators and data analysts can remain safely onshore whilst the operation takes place and data can be sent ashore and verified in near real-time using the USV’s satellite communications.

This satisfied Shell’s commitment to accelerate the transition of their business to net-zero emissions and to integrate sustainability within their business strategy. Following the successful PMT installation in 2019, a five year project was agreed where Sonardyne are responsible for the data delivery to Shell and XOCEAN are responsible for delivering the transceiver to the field for data collection via their USV.

The results

The project began in January 2020 and this was the first time a remote USV data harvest was completed offshore in Norwegian waters by any operator.

Whilst the USV and HPT 3000 were in Norwegian waters surveying the Ormen Lange site, the Sonardyne and XOCEAN personnel never left their bases in England and Ireland.

The data harvest was monitored in real time, 24/7 and the two teams were in contact with each other as well as the remote equipment. This mean that data was being monitored by our team as it was collected and there was no risk of the USV returning with missing or irrelevant data. Had there been any missed or partially collected data the Sonardyne team could ask the XOCEAN team to return to recollect from a particular PMT whilst still in the field, rather than waiting until the vessel returned and having to send it out again.

Successful data harvests have been conducted yearly since 2020 and continue to be a cost effective, low impact operation. This year we collected data from the Ormen Lange site twice, in Spring and Autumn.

If you think you have a similar challenge for us, contact us today.