A 'custom-off-the-shelf' product provides a timely solution for Dana Petroleum

Our experience and expertise allowed us to rapidly adapt our off-the-shelf technology for Dana Petroleum. This delivered a cost-efficient, low environmental impact, and timely solution for them to monitor their suspended wells in the North Sea.

The challenge

As they reach the end of their productive life, oil and gas well heads still need to be monitored whilst suspended – for up to five years, before they become fully abandoned / decommissioned. A regime must be in place to monitor the assets ‘in perpetuity’ to meet government regulations. As this is ‘abandonment expenditure’, rather than capital expenditure, any monitoring schedule must be conducted as cost effectively as possible.

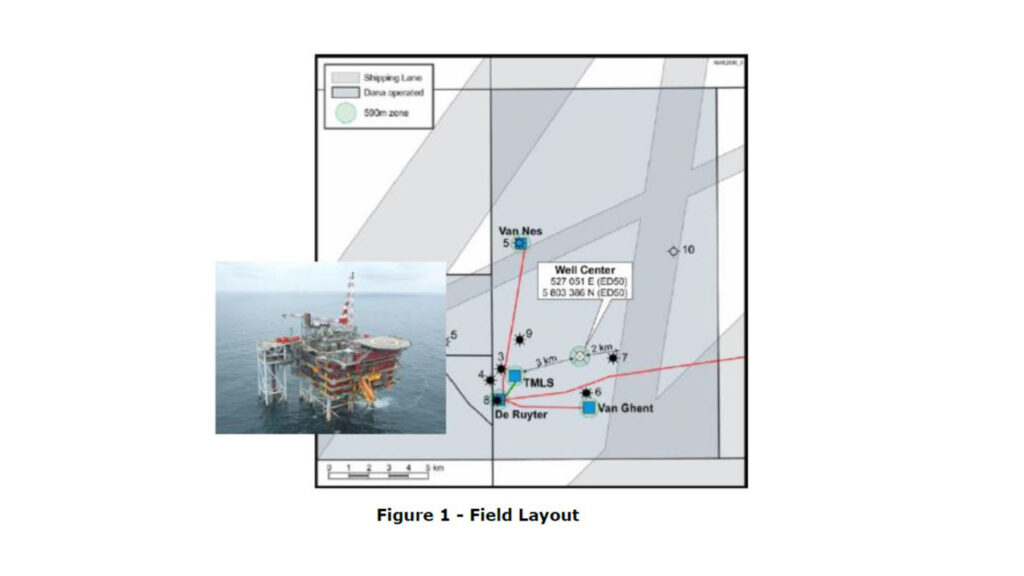

Dana Petroleum (Netherlands) was faced with one such challenge in early 2023 when they needed to plan and implement a well annulus monitoring schedule for suspended wells at their Van Ghent and Van Nes subsea wells, situated in the North Sea approximately 60km West of The Hague. The wells were situated alongside others still in operation and although the topside platform remained, communication links with the sensors on the suspended subsea wells had been lost. There was an additional challenge of the system needing to be in place within 12 weeks.

The solution

The ’simple’ solution would have been to lay new communication cables from the suspended well heads to the topside platform to enable the monitoring. But this would have been lengthy, expensive and carbon intensive, involving bringing in large vessels to lay long stretches of subsea cables. A quicker, cost effective and lower carbon solution was needed. Having heard about Sonardyne’s experience and expertise in long-term subsea asset monitoring, Dana Petroleum approached us for a solution.

We have many years’ experience in providing subsea pressure and temperature data directly from well downhole gauges, mostly during the appraisal phase in a field development, providing essential data to the reservoir engineers before connection is made to the offshore or onshore facility.

Although Dana Petroleum’s requirement was well within our capabilities, there were some initial unknowns such as; field layout, pressure gauge model and manufacturer and how the equipment would be mounted to the subsea manifold. Also, which topside would be most suitable for data harvest? Something which is typically dictated by the vessel size, noise profile and water depth. The timeframe was also very challenging.

In the following weeks, Dana Petroleum provided information on the field layout, drawings of the subsea infrastructure and a strong specification for a system capable of monitoring the annulus pressures at both locations. Having received this, we were able to provide illustrations of previously designed bracketry, 3D CAD images of our potential offering and expert advice to work out the optimum placement to enable best line of site for data harvesting. With a firm specification and known time constraints we looked to our off-the-shelf products with a view to creating a semi-custom solution with our projects team.

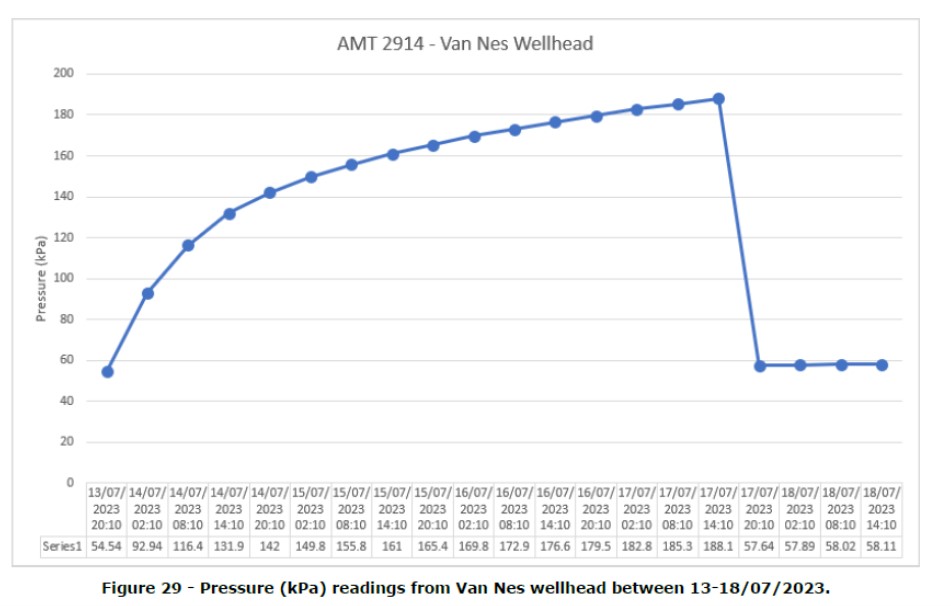

The obvious choice was to make custom alterations to our Autonomous monitoring transponder (AMT). The AMT has been used in a wide variety of different applications including overburden monitoring and pipeline movement monitoring, all utilising and autonomously logging pressure sensor data. These solutions can operate autonomously over long periods of time, over five years – depending on deployment – logging data and making it accessible for wireless upload.

The topside platform of choice was a Nano topside equipped with a ruggedised laptop running Sonardyne’s Monitor software fitted to a small crew transfer vessel that would pass by the wells at regular intervals, delivering workers to the platforms. The size of the vessel dictated a small portable solution but other options are available for all sizes of vessels.

Once the seabed and topside products were selected, custom modifications were made by the projects team to the AMT, allowing the pressure sensor to be connected to the annulus via a flange – rather than inside the AMT –to give flexibility in the location of the AMT and achieve best line of communication with the Nano transceiver when it passed overhead.

A factory acceptance test was witnessed by Dana Petroleum where our projects team provided documentation and coordinated the testing. Following this the equipment was shipped and ready for installation – all within a few months!