Ranger 2 – it's anything but standard

Carbon Capture and Storage is increasingly seen as one of the key measures to help us reduce greenhouse gas emissions. Capturing it is one thing, storing it and making sure it stays stored is another, which is why the National Oceanography Centre (NOC) and others have been working to understand the nature of potential CO₂ leaks and test sensor capability to detect these.

The challenge

Understanding how carbon dioxide behaves in deep water environments requires specialist equipment and multiple sensors. The various systems need to be able to work together smoothly, fly through the water without drag and reliably stay in contact with above water instrumentation.

One of the NOC’s most recent missions focused on CCS. As part of the European Union Horizon 2020-funded Strategies for Environmental Monitoring of Marine CCS (STEMM-CCS), it focused on CCS in the North Sea.

The solution

The project, involving researchers from Germany, Norway, Austria and the UK, and industry partner Shell, centred on the decommissioned Goldeneye field, about 100 km offshore Scotland in about 120 m water depth. In May 2019, researchers and scientists onboard the RRS James Cook set out for Goldeneye for an intense period of scientific activity.

The aim was to simulate carbon dioxide (CO₂) leaks from the seafloor in order to test various sensors and systems for their ability to detect potential CO₂ leakages. This would help the teams understand how the gas behaves, and discover if seepage from the seabed worked its way up through the water column.

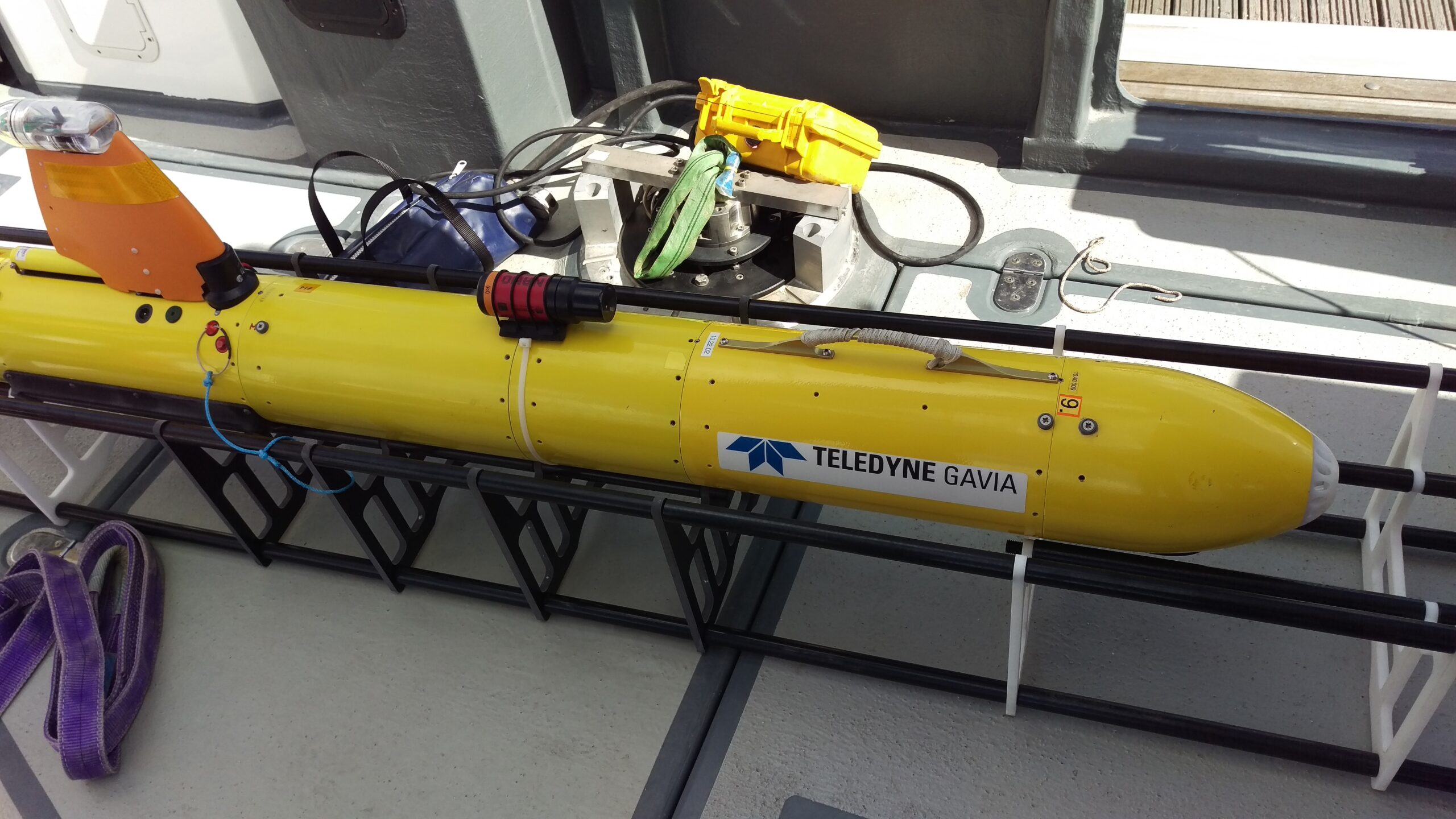

For mapping the area and wide-area chemical sensing, they used a Gavia autonomous underwater vehicle (AUV) called Freya. Because the Gavia had been adapted specifically for the mission – including fitting additional sensors to its body – operators were uncertain about how it would now fly through the water.

Our Ranger 2 system has underpinned the ocean science carried out by the RRS James Cook since it went into NOC service in 2006. It’s helped to track a whole host of vehicles and instruments, including NOC’s Isis ROV to 5,000 m deep. Indeed, on this latest mission, Isis, with a 6G Wideband Mini Transponder (WMT) onboard, was tracked using Ranger 2 during its many trips to the seafloor where it helped to accurately install an array of seabed equipment, sensors and instrumentation.

The Gavia Freya is classed as a low-logistics vehicle – meaning that only two people are required to deploy and recover it. Typically, Gavias measure anywhere between 1.8 m and 4.5 m in length, and just 200 mm in diameter. So when it came to choosing which USBL transponder to equip Freya with, there was really only one option Nano.

It’s our smallest 6G-enabled USBL transponder (just 160 mm tall by 52 mm diameter) and comes with features such as wireless charging, depth sensor and lightweight plastic construction. For this mission, Freya’s mission payload included a GeoSwath system for side scan sonar and bathymetry, mounted externally to the hull, supported by additional buoyancy. This provided a convenient place to the site the Nano. Freya was also used for photographic surveys and chemical sensing for pH using the SeaFET system.

For maximum operational flexibility, the RSS James Cook is permanently fitted with both our HPT 5000 (wide area) and HPT 7000 (deep water optimised) transceivers to separate, through-hull deployment spars. Whilst either of these medium frequency transceivers is capable of tracking a Nano, the shallow water at Goldeneye meant that the Gavia was tracked with the HPT 5000.

The results

“We were able to use the displays from the Ranger 2 to see that the Gavia was getting down to its working depth, usually around 100 m, as we were mapping the seabed,” says Mike Smart, Glider Engineer, Marine Autonomous and Robotic Systems, National Marine Facilities, NOC. “This was very useful as there was quite a lot of uncertainty about how the Gavia would behave given the extra payload it was carrying. Tracking data from Ranger was also shared across our network with survey and science teams elsewhere onboard.

“Being able to track the progress of the mission was another nice feature. With a much longer and heavier configuration of Gavia than we usually deploy, the time it needed to resurface was longer than we had predicted. So, being able to view the vehicle’s precise location, aided by regular depth updates from the Nano, meant we could more accurately predict surface times and not be anxiously waiting for Freya to reappear at the end of her survey run.”

This is just the latest time we’ve been involved in the work towards CCS. Past work demonstrates how our Sentry leak detection sonar and our Solstice side scan sonar are able to detect leaks, as static and dynamic sensors. Our instruments have also been shown to be able to support so-called chemical “sniffers” that can detect CO₂ (see Baselines 12 and 18).

While it’s still an emerging area, the industry is getting closer to making CCS offshore a reality – the first offshore carbon storage license was awarded in the UK in 2018, followed by a new license for a significant storage site in Norway in 2019.