Operating a small robotic platform in any marine environment is not without its challenges. Reliability and precision with accurate positioning data are key for safe operations and where repeat inspections or surveys are needed.

The size of the platform may present its own limitations, restricting the size and weight of any payload and therefore the extent of its operational capabilities. Environmental or locational factors may also play a part in the reliability of operations. Most navigational and positioning payloads use magnetic compasses to provide heading. This reliance on magnetic heading makes the platform susceptible to interference from ferrous materials in its surroundings. These could be wind turbine or energy platform monopiles, wreckage or unexploded ordnance (UXO) on the seabed, the presence of vessels / submerged infrastructure in harbours and coastal locations or even just naturally occurring ferrous minerals in the seabed.

These factors introduce heading errors that compromise the supervised autonomous functions of the platform, particularly when following line headings between reciprocal bearings. Even minor heading inaccuracies can cause cumulative deviations over extended missions, leading to imprecise data and potentially requiring time-consuming survey line re-runs.

Any inaccuracies during survey when locating UXOs are particularly unwelcome, by their nature most UXOs are located based on magnetic signature. So, any poor navigation during the wide area or detailed UXO survey can be misleading and potentially dangerous. With repeat inspections of monopiles, for example, ensuring the survey platform returns to the exact same spot on each visit is important to ensure no anomalies or potential problems are missed.

Heading accuracy

0.15°

Regardless of the environment

Depth rating

0

m

Weight in water

0.6kg

“Historically, smaller electric vehicles have been limited in the amount of work they are capable of due to size, power and operational limits presented by weather conditions and surroundings.

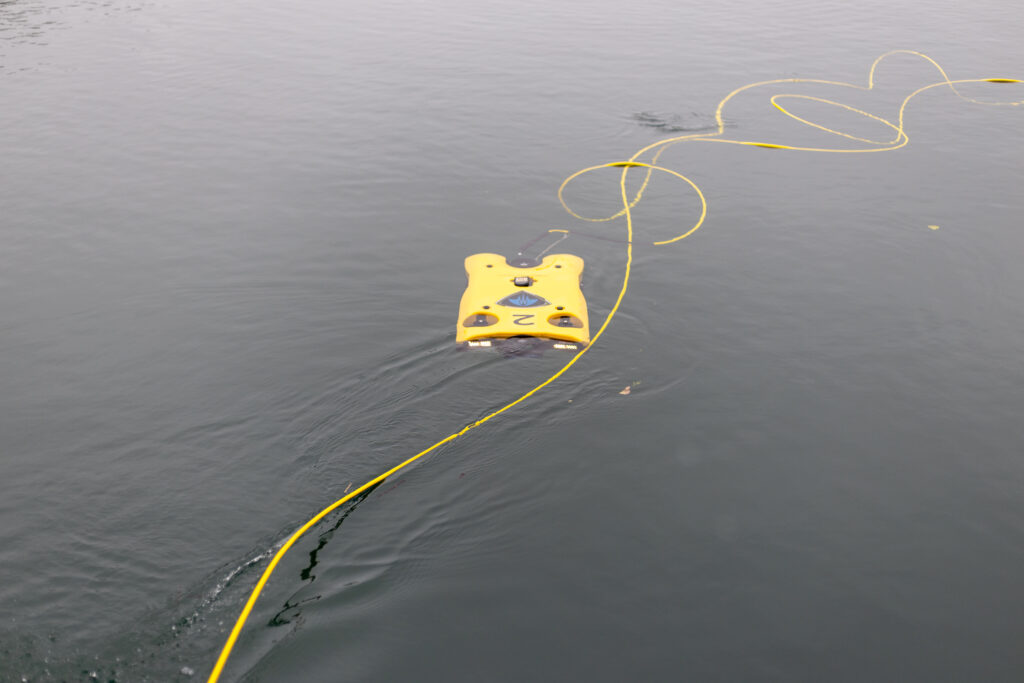

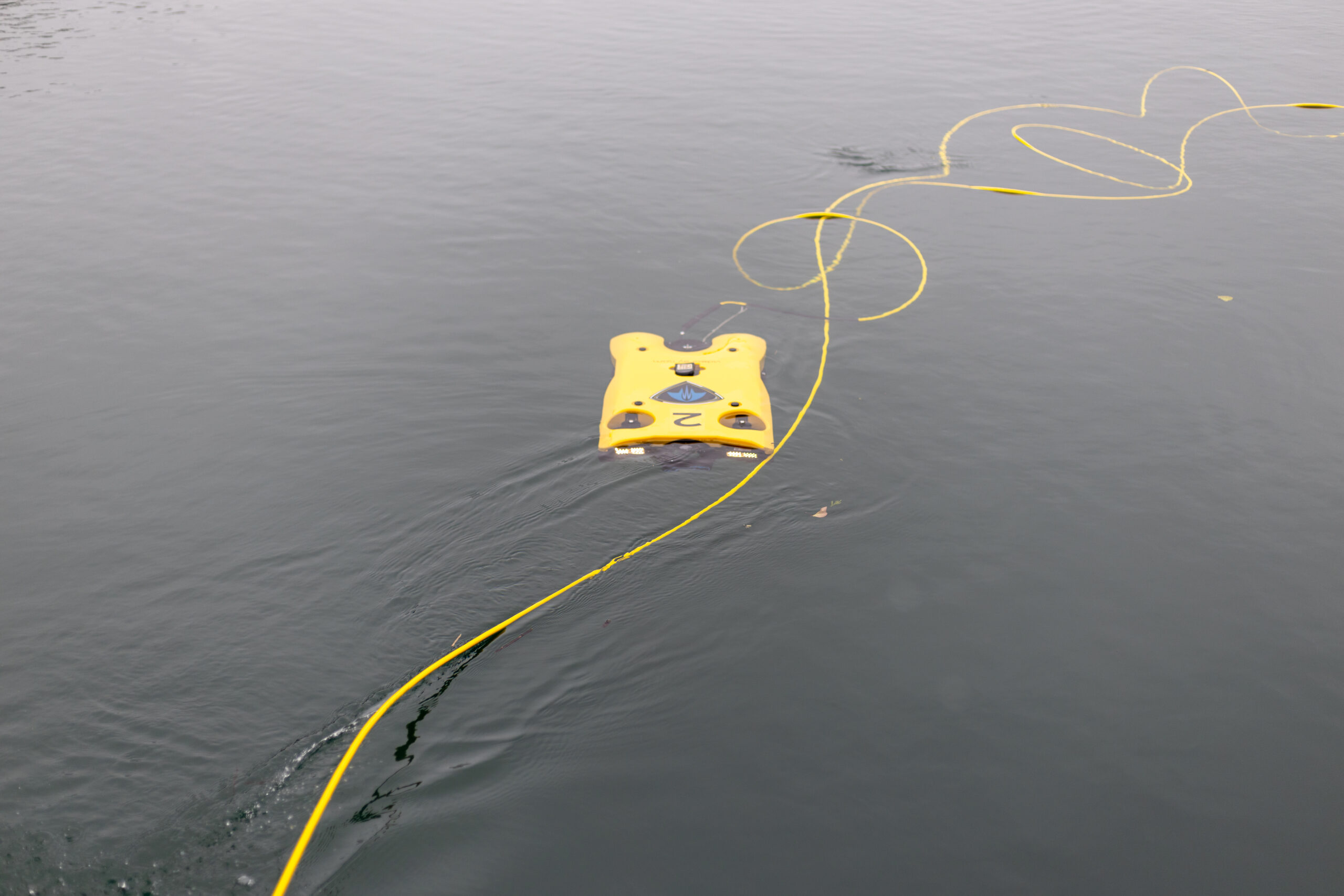

Recent iterations of handheld ROVs such as the VideoRay Defender have looked to change what electric ROVs are capable of, while maintaining a platform that is easy to mobilise, operate and maintain. That said, the ROV is only as powerful as the tooling that it holds, so it still requires support from companies such as Sonardyne, to reduce the form factor and weight of their tools and sensors, to enable their integration and deployment offshore.

Atlantas Marine have already been utilising the SPRINT Nav Mini to great success on our Ocean Modules V8 M500 platform, but the latest SPRINT-Nav U will allow us to go further and integrate it onto our VideoRay Defender ROVs, and provide another service that we can offer our customers – a hand-launched ROV, that can be mobilised in as little as half an hour, transported to site in the back of an car” Mark Salter, Senior Project Manager, Atlantas Marine.

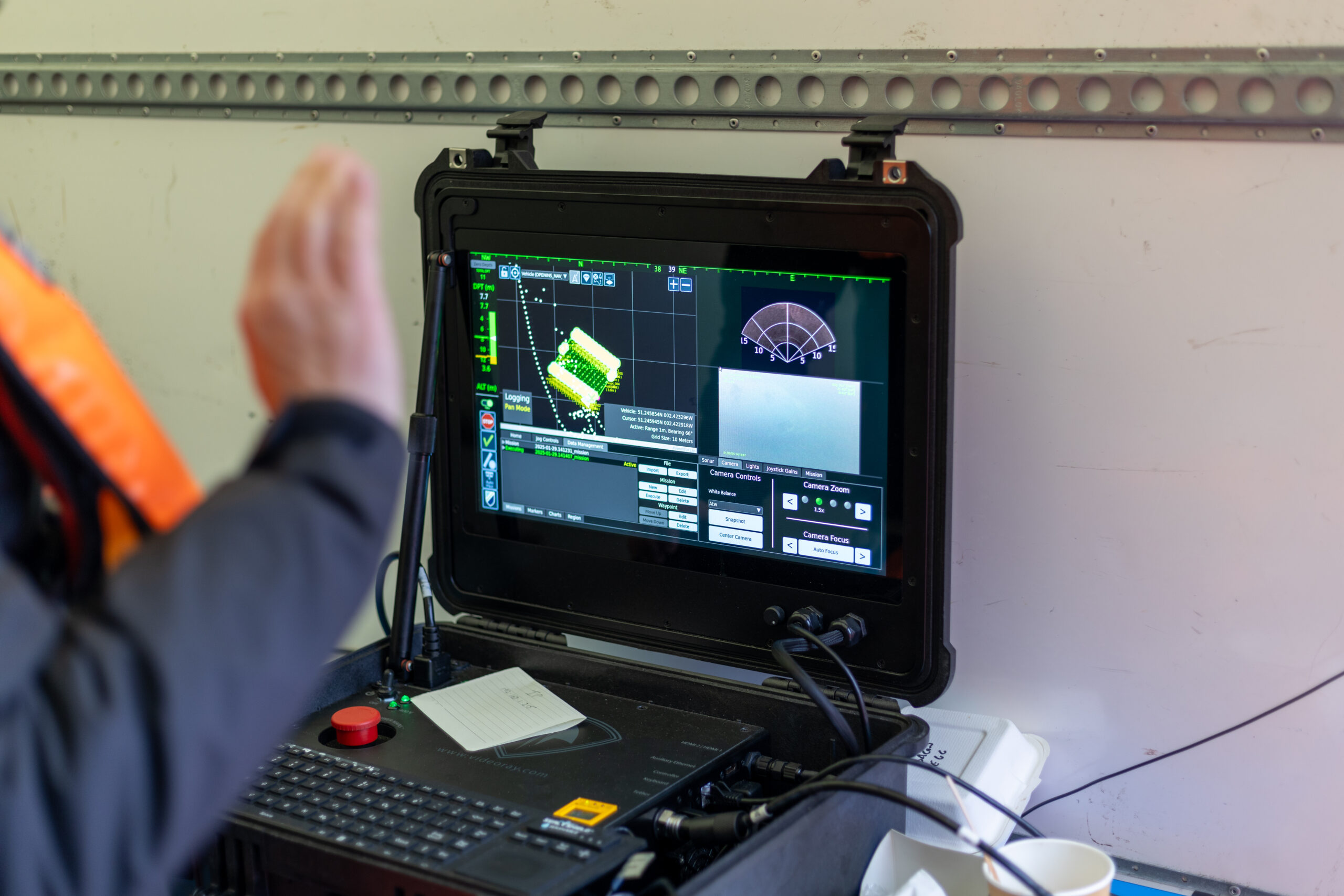

“Like the other hybrid navigators in the SPRINT-Nav family, SPRINT-Nav U’s true north seeking gyrocompass means that it delivers reliable subsea navigation even when in close contact with the types of environmental factors outlined above. With its ultra-compact form factor (135mm X 114mm) and a weight in water of just 0.6kg, SPRINT-Nav U gives unrivalled navigation capability to small marine robotic system allowing users to maintain a heading accuracy of 0.15° regardless of environmental factors.

“SPRINT-Nav U has been designed with our customers in mind. We’ve been speaking to them for a number of years about their aspirations for operations with small platforms. With the help of valued customers like Atlantas Marine, our trials have demonstrated a variety of use cases for this new, compact navigator and we’re excited to work on many more innovative uses in future.” Aidan Thorn, Business Development Manager – Marine Robotics, Sonardyne.

Small, light, precise

SPRINT-Nav U is simple to integrate into any marine vehicle along with other payload sensors and uses same field-proven web user interface found on the SPRINT-Nav Mini. Pre-calibration in the factory also means that SPRINT-Nav U is incredibly quick to set up and deploy on site with an alignment time of as little as five minutes, compared to the standard 15-20 minutes of other gyrocompassing inertial navigation systems, making it the world’s fastest aligning hybrid navigator.

“SPRINT-Nav U can turn any marine robot into a survey grade platform. For UXO and asset inspection it drastically improves deliverable data quality. As part of the proven Sonardyne SPRINT-Nav family, customers can be assured of reliable, accurate navigation and positioning every time, no matter the operating environment.” John Houlder, Senior Product Manager, Sonardyne.

“Of particular significance to us, is the work we undertake on offshore wind turbines. With a high AC voltage running through the subsea cabling, and the strong magnetic signatures associated with that, plus the ferrous nature of the turbines themselves, the SPRINT-Nav U allows us to offer our customers a level of accuracy and precision that was previously not possible. It allows us to state with much higher confidence the location of any faults and anomalies, and allows us to repeat inspections, year on year, as we document the changing condition of those faults. With the positioning and control managed through Greensea, we can set up autonomous routes and sea patterns with more accuracy and precision than even before, especially in the environments we most commonly find ourselves.”

Mark Salter, Senior Project Manager, Atlantas Marine.

“Providing improved accuracy when operating in ports and areas where large metallic objects are buried on or beneath the seabed, improves not only the reciprocal bearings of the lanes the ROV is flying, but feeds a more accurate heading into the navigation solution which is streamed to the surveyor.

Beyond seabed surveys, the ability to maintain a stable heading while piloting a compact inspection-class ROV through culverts with rebar or complex subterranean tunnels is a key advantage. It reduces the need for frequent heading corrections and ensures precise navigation when traversing long distances. This ultimately enhances the quality of deliverables for our clients, providing us with a competitive edge when deploying our equipment.”

Richard Stanley, Project Leader, Atlantas Marine