Transponders provide reliable releases for Allton offshore Norway

When placing vital equipment such as Nodes on the seabed you need to be sure that you can retrieve them. During the development process, a lack of other products available in the marketplace that met their requirements led Norwegian technology and service company Allton to turn to Sonardyne for a solution.

Starting life as Petromarker in 2005, Allton has been operating offshore Norway for almost 20 years. The company specialises in: marine subsurface electro-magnetic (EM) data acquisition and imaging for hydrocarbon exploration and production, CO2 measurement, monitoring and verification for carbon capture sequestration and marine mineral exploration. It has now expanded its technology and service offering to include multiphysics joint acquisition of both EM and seismic OBN data.

With their innovative multiphysics platform relying on the data they retrieve from both EM and seismic OBN nodes, Allton need to be one hundred percent confident that they can locate and recover their nodes once they’ve been deployed. This can be from depths of up to 3,500 m in often challenging conditions.

When Allton expanded its operational work department and began the redesign of its subsea equipment, a search began for new and reliable solutions as existing transponders and release mechanisms were unsuitable for their specific requirements.

With several decades of subsea transponder and release manufacturing experience, Sonardyne was an obvious choice for a solution.

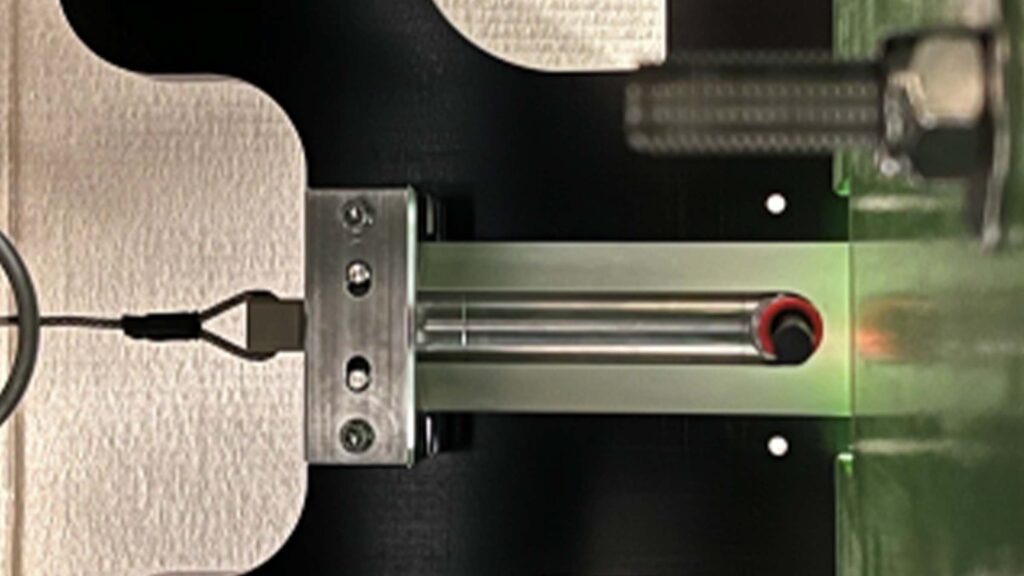

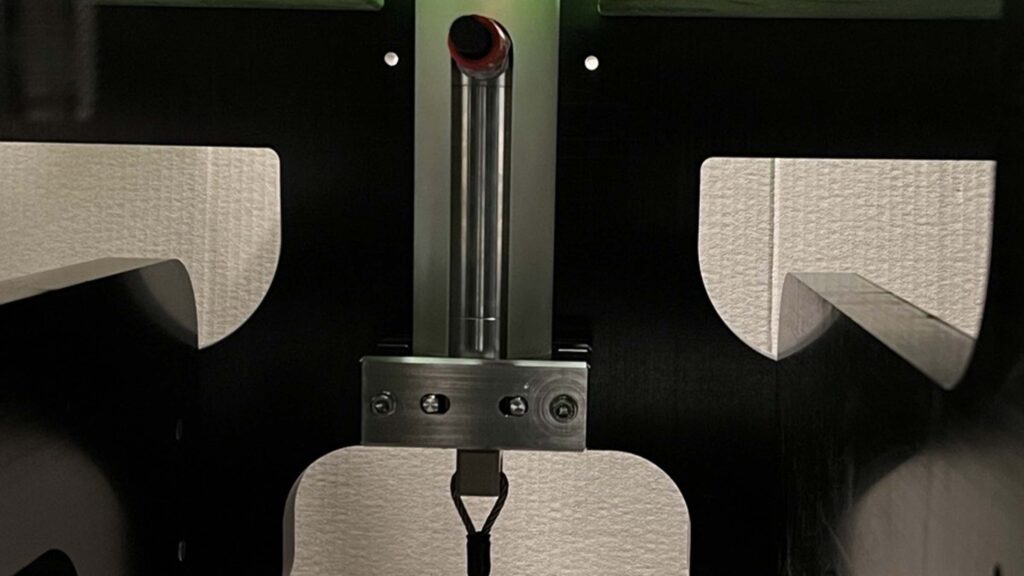

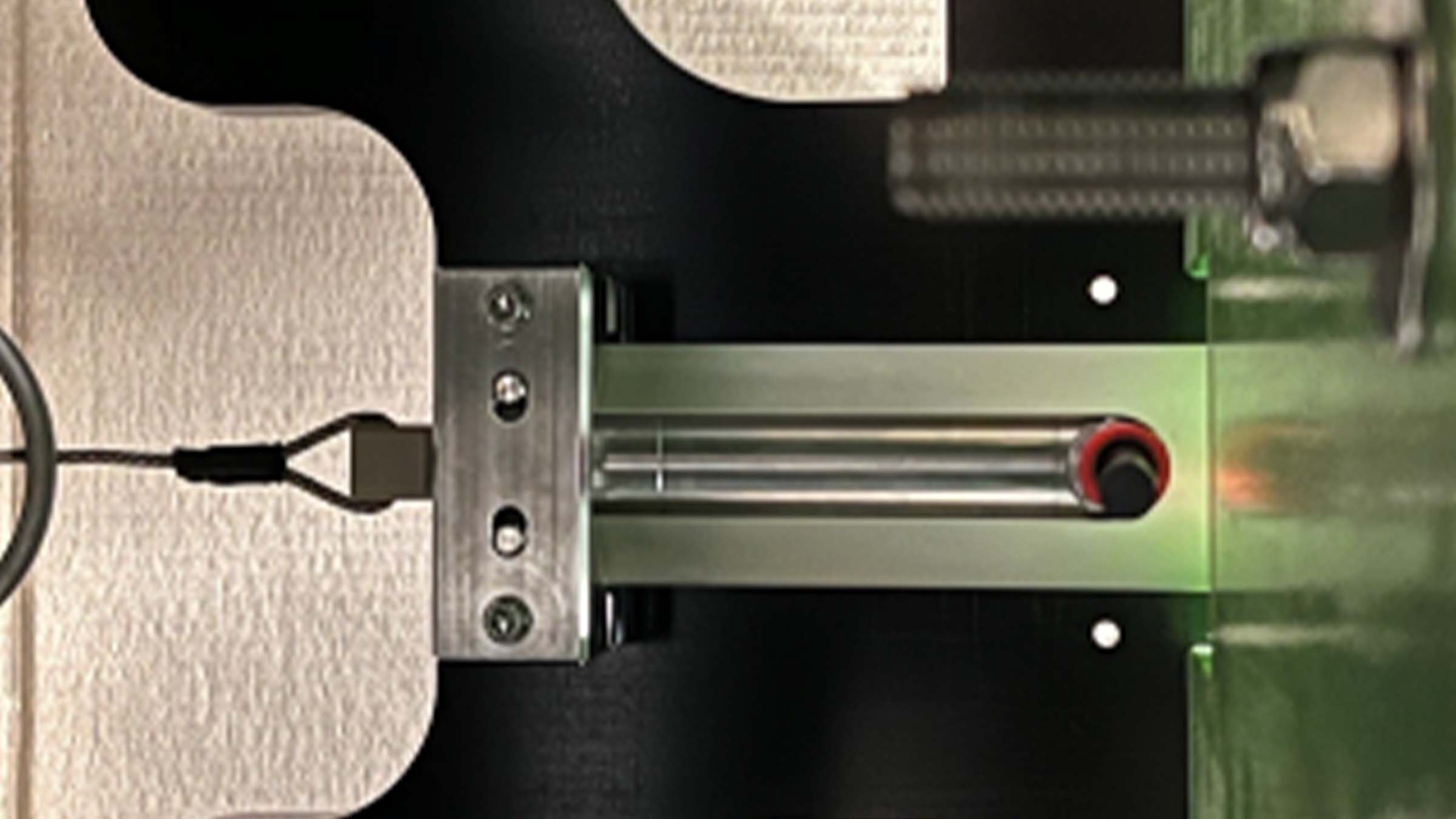

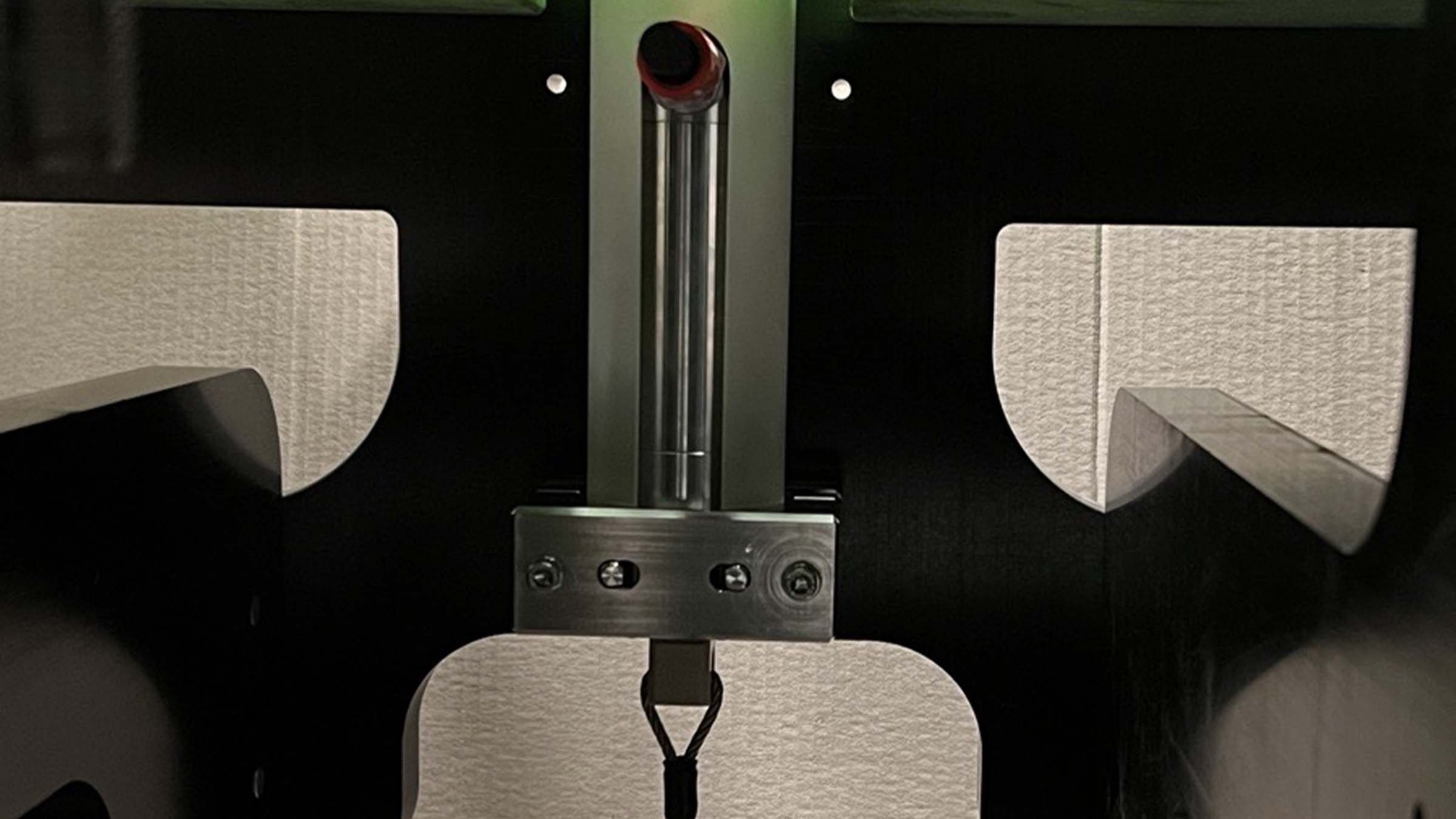

Our RT 6 family of acoustic release transponders combine the extensive track record of our previous models with the flexibility of a 6G hardware platform, meaning they can be deployed, located and released using any of our Ranger 2 USBL systems or 6G topsides.

An acoustic release transponder is fixed to a subsea asset so it can be found and recovered. An acoustic signal from a surface vessel locates the transponder on the asset. A second acoustic signal then tells the transponder to release the mechanism anchoring the asset to the seabed so that it can be retrieved.

Having gained a full understanding of Allton’s requirements, our engineering team worked closely with them to custom modify an existing RT 6 model to meet their exact needs. Aleksander Kristiansen, Supply Chain and Asset Manager, from Allton explains, “The custom manufacture of our RT 6-4000 was based on an existing model (RT 6-1000) which Sonardyne modified to suit our operational needs. This included extending its range and adding a secondary burn release circuit.

Working with our customers to fully appreciate their needs and the challenges their businesses face enables us to develop solutions for their specific operations. As Trevor Barnes, Sonardyne Sales Manager, explains: “Allton was looking for a robust, reliable acoustic release to give them confidence in retrieving their equipment from a range of depths. Whilst our RT 6-1000 is perfect for depths of up to 1,000 m, Allton operate in depths of up to 3,500 m so our engineers worked closely with them to develop an RT 6-4000 to enable this. A secondary burn-wire release was also added at their request, as a backup in the unlikely event that the first acoustic release fails.”

Aleksander Kristiansen continued “Sonardyne were always willing to assist and put the right technical expertise onto the variety and wide range of tasks to solve our many, often complex at times, challenges. Their creative ideas were well aligned with our expectations and letting us borrow equipment for an extensive time to conduct in-house testing was much appreciated. It gave us further confirmation that we were making the right choice in the RT 6 releases.”

Allton’s nodes are now fitted with RT 6-4000 acoustic releases to ensure that they can be reliably located and retrieved from the seabed at all their operating depths and in any conditions.

They can now provide data across all of their services with confidence that they have consistent, reliable access to their network of nodes.

Our standard RT 6s come in three depth ratings, 1,000 m, 3,000 m and 6,000 m and all use our workhorse Ranger 2 USBL system or deck topside to command and track. Some models can even be controlled using an Android app.

If you have a similar operational challenge, take the worry out of mooring and retrieving your kit and talk to us today.