6G modems make the connection between data and decisions

Two years ago Shell Exploration and Production (Shell E&P) approached Metocean organisation RPS Evans Hamilton Inc to expand the capabilities of their service to measure seabed current profile data at the Walker Ridge area in the Gulf of Mexico.

The challenge

Operations in deep and ultra-deep water (6,000 to 10,000 feet) are challenging for drilling, construction and pipeline installation. These challenges can be made safer and more efficient through a good understanding of subsurface current patterns. For this to be effective, wireless transmission of observations to the surface are essential for instant analysis.

This type of data is usually obtained using acoustic Doppler current profilers (ADCPs) mounted near the surface looking down through the water column. As operational depths increase, a second ADCP, placed on the seabed looking-up, provides the additional data.

The most common approach involves deploying the second ADCP for several months at a time. This is set to log bottom currents at intervals from minutes to hours. While this data is extremely useful for site surveys and planning exploration activities, the delay between collection, instrument recovery, download and analysis, means its usefulness is limited. Particularly when needed for supporting on-site decision making during operations (including complying with government directives). A faster way to retrieve the data collected by the ADCP is needed.

The solution

An acoustic modem directly connected to the ADCP provides a cost-effective and increasingly popular option for providing instant access to the data collected. The modem enables access to the data from almost anywhere in the world.

But not all acoustic modems are made equal. It’s vital to make sure when choosing one for use in an application such as offshore drilling, the signal processing and error correction techniques reliably deliver critical data payloads over long distances and, if needed, through acoustically hostile transmission paths.

RPS Ocean Science identified Sonardyne’s 6G (sixth generation) wireless communications platform as the optimum solution. 6G has an enviable reputation across the region. Today it’s the only acoustic technology to have been proven as a successful monitoring solution during a well containment situation.

The seabed component of the monitoring system incorporated a Sonardyne Compatt 6 telemetry transponder interfaced with a Teledyne RDI Workhorse 300 kHz ADCP. These were mounted together in a deployment frame. 10,000 feet above, a Sonardyne HPT modem deployed from the rig acted as the surface receiver. It was enclosed within a rugged cage to protect it during deployment and recovery phases, and weighted to prevent drifting in high surface currents.

The HPT was integrated with the data collection system RPS Ocean Science had previously supplied to the rig, this included a 38 kHz ADCP at the surface and load handling system. The Compatt 6G modems and ADCP were deployed by ROV on the seabed at a depth of 9,970 feet, approximately 150 feet away from the rig’s BOP.

After establishing reliable seabed to surface communications, data collection was initiated. The acquisition system is designed to receive and display data from the surface and bottom ADCPs at 10 minute intervals.

Modem 6

0

m

operating depth

0

bps

acoustic comms

The results

Following initial system deployment, the signal analysis tools built into the Compatt 6 and HPT enabled the bidirectional communications link to be optimised for the local conditions. This resulted in highly reliable and low latency data return rates.

Water velocity profiles were generated from approximately three metres to 100 m off the seabed. The profiles were composed of 50, two metre bins. Data was averaged over 75 seconds at a 1 Hz sample rate. Velocity and direction profiles were processed by the subsurface instrument and transmitted to the rig’s data acquisition system where profiles were displayed, along with the velocity and direction profiles from the surface ADCP, on the platform bridge.

The data has been utilised by the metocean team to support exploration operations in daily advisories as well as providing a unique perspective on potential Topographic Rossby Waves thought to be a common feature in the area. Processed data files were also transmitted to our client’s shore-based server and the National Data Buoy Center (NDBC) in near real-time.

A demonstration of the system’s capability took place during the summer of 2015. Since then, the RPS-Sonardyne solution has proven to offer reliable self-contained operation with long service intervals. The configuration of the upward looking ADCP and Sonardyne 6G digital modem technology perfectly complements conventional near-surface and mid-column current monitoring. It also contributes toward lowering operational risk and increasing the safety of drilling, survey and ROV operations in deep water.

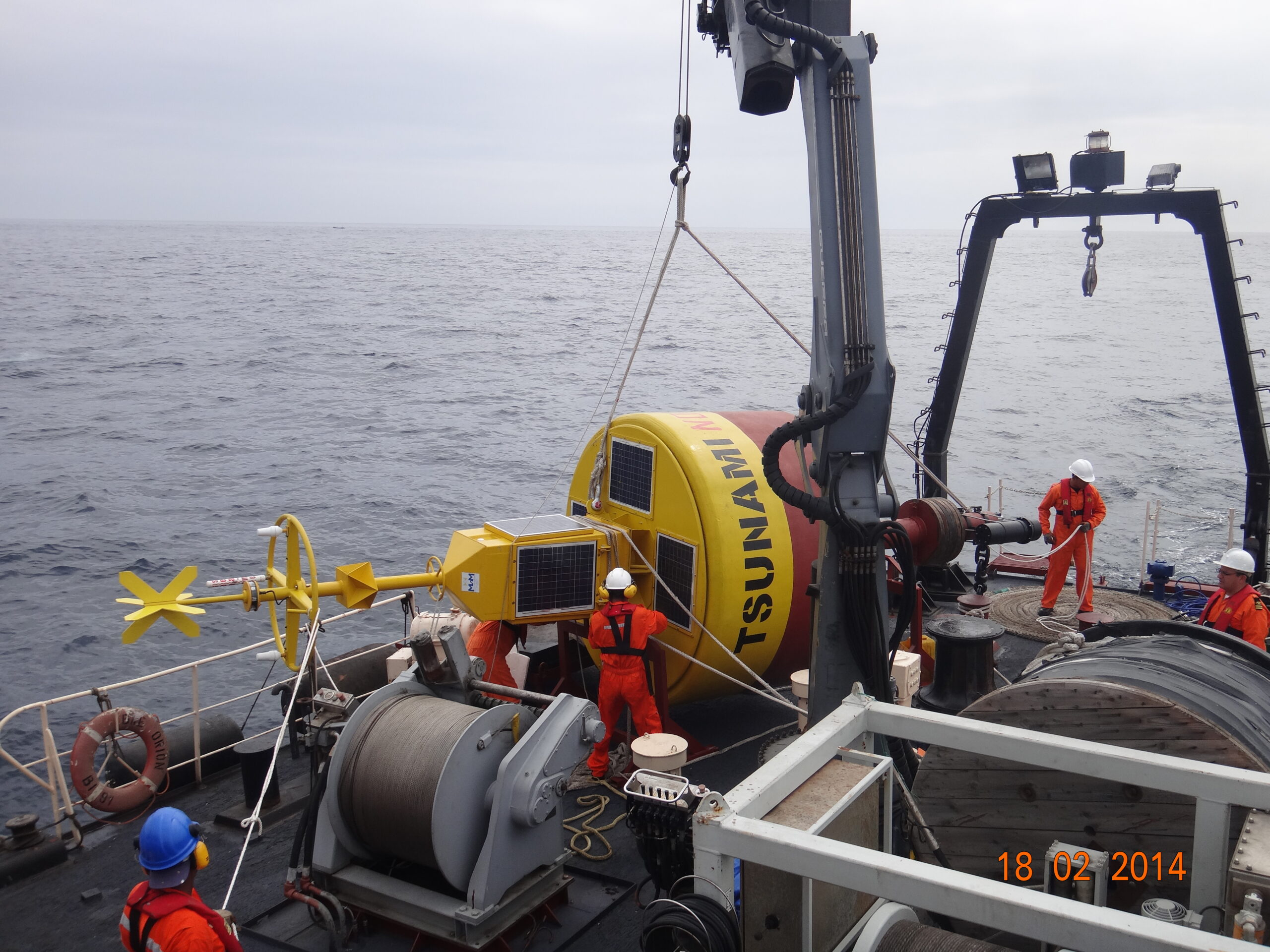

Underpinning the Indian Tsunami early warning system

Sonardyne Bottom Pressure Recorders (BPR) have been at the heart of the Indian Tsunami Early Warning System (ITEWS) since its establishment in 2007. Based on Sonardyne’s workhorse Compatt transponder, our BPR instrument was developed in direct response to the devastating 2004 Indian Ocean Tsunami.

The challenge

30% of India’s population (ca. 420 million) live on its 7,500 km long coast and are consequently highly vulnerable to devastating Tsunamis such as the one that occurred on 26th December 2004. This killed over 230,000 people in the Indian Ocean region, with 10,749 confirmed deaths in India and another 5,640 missing. While seismometers are an important component of Tsunami warning, only Bottom Pressure Recorders can detect the passage of an actual Tsunami. Indeed, Tsunami warnings based purely on seismic data have the potential to produce false alarms, which are costly in wasted evacuations and undermine public confidence.

The essential elements of a Tsunami Detection System (TDS) are:

1. The capability to detect a Tsunami – While a Tsunami may arrive at the coast many metres high, in open ocean they pass almost imperceptibly and may only be a few centimetres in height, although this elevation in sea-level can be maintained for as long as 20 minutes.

2. The functionality to provide this detection ashore with sufficient warning time – A Tsunami travels (in ms-1) at roughly the square root of the depth of the water (in m) multiplied by the acceleration due to gravity (9.81ms-1): In short, it travels faster in deeper water, so for example, in 1,000m of water it will be travelling at over 1,100 kmh-1. In India’s case, the Andaman-Sumatra and Makran subduction zones are located within a few hours Tsunami travel time of the Indian coastline

3. High reliability in delivering the detection information ashore – BPRs, as the name implies are deployed on the seabed, so rely on robust telemetry, which has to operate even in poor weather conditions continuously 24/7/365.

The solution

The catastrophic 2004 Indian Ocean Tsunami led Sonardyne’s founder, John Partridge, to initiate development of a variant of the Compatt 5 seabed transponder to detect a Tsunami passing overhead.

With an extensive track record in the oil and gas industry, this instrument was ideal to form the heart of a TDS requiring very high reliability. Nevertheless, integration of a Digiquartz pressure sensor to enable the Compatt 5 as a BPR, required significant development. This particularly involved reduction of the power required for continuous operation on battery power. Similarly, a new transceiver with low quiescent power, capable of long endurance deployment on a surface telemetry buoy, also had to be developed.

Development was so rapid that when India’s National Institute of Ocean Technology (NIOT) in Chennai, started looking for a TDS in 2005, it was ready for competitive field trial. Sonardyne’s solution was subsequently selected in 2006, leading to deployment of operational systems in the Bay of Bengal and Arabian Sea in 2007.

In normal operation the Digiquartz pressure sensor in the BPR continuously measures water pressure and this data is stored every 15 seconds. The pressure data is then acoustically transmitted every hour to the surface, where an acoustically baffled transceiver, mounted beneath a buoy, receives this data. The buoy is linked to NIOT’s Mission Control Centre (MCC) by satellite communications, so that not only can data be transmitted ashore quickly, but also the health of the BPR is remotely monitored and, if necessary, reconfigured.

Embedded in the BPR is the National Oceanic and Atmospheric Administration’s (NOAA) Tsunami detection algorithm, which compares each measurement to the predicted pressure [Figure]. This predicted pressure uses the previous 3-hour history to take account of tide, weather and temperature variation. Should the difference between the two exceed a programmable default threshold of 3 cm for two consecutive samples, the BPR switches into Tsunami Alert Mode, which then initiates a sequence of data transmissions for the next few hours.

Sonardyne’s Wideband acoustics are central to the functioning of the system, and with the subsequent replacement of the Compatt 5 with Compatt 6, Sonardyne’s latest TDS offering is equipped with the most robust and efficient wideband acoustic telemetry available.

Of India's population

0

%

live on its long coast line

Monitoring

24/7/365

The results

Soon after the first batch of BPRs were deployed, on the 12th September 2007, the system detected its first Tsunami, which was triggered by an 8.2 magnitude event off the coast of Sumatra at 04° 30’ S 101° 18’ E. How the Tsunami generated was tracked across three of the Indian Tsunami Buoys (ITB) is shown in the gallery.

Located between 1,760 – 2,300 km away, all three stations recorded the seismic ground wave arrival between 7 – 12 mins after the event started. Between 2 – 3 hrs later, the wave itself, which was less than 10 cm in height, passed over the three BPRs, indicating that it had travelled at between 740 – 800 km/h over this period.

Today, Sonardyne’s TDS continues to deliver bottom pressure and event data to NIOT, which is responsible for delivering sea-level data to the Indian Tsunami Early Warning Center (ITEWC) at the Indian National Centre for Ocean Information Sciences (INCOIS) in Hyderabad. In 2014, NIOT reported that system data availability had been 98.83%, with a Mean Time Between Failure (MTBF) of 1.62 years, noting that the majority of these failures were due to external impacts, including weather and human interference with the surface buoys, resulting in damage to surface communication and data systems.

Greater efficiency, lower overheads, with underwater autonomy in deepwater seismic

Shell Brasil, in partnership with Petrobras, Sonardyne and Brazilian research institute SENAI CIMATEC are working together to bring a step-change to 4D seismic data gathering in Brazil’s deepwater pre-salt region.

Discover how we’re collaborating to develop innovative autonomous technology that will make monitoring these challenging deepwater fields more efficient, with fewer people and lower environmental footprint.

Scroll down to read this case study in Portuguese.

The challenge

Seismic data is an essential part of offshore field development activity, especially to support proactive reservoir management and production optimisation. Techniques for gathering this data have evolved dramatically over the decades; from the use of marine streamers for large exploration seismic campaigns to the now routine use of remote operated vehicles (ROV) to deploy ocean bottom nodes (OBN) for high-resolution imaging of pre-salt reservoirs.

Yet, gathering seismic data for pre-salt reservoir imaging remains intensive work. It involves large, costly and carbon-emitting crewed vessels for deployment and recovery of, typically, thousands of nodes. As an example, for a 10-month campaign over one of Brazil’s giant pre-salt fields, a node handling vessel could emit close to 10,000 tons of CO₂. Costly and complex operations can mean a reduction in frequency of surveys, including of those done to gather what’s called time lapse or 4D seismic data, which is required to monitor the pre-salt reservoirs.

Shell and Petrobras came to us believing that there could be a lower-cost, more sustainable, way of acquiring 4D seismic data, as well as other parameters such as seafloor subsidence, to help better monitor reservoirs. They also saw this could be done with a lower environmental footprint and while keeping more people safe.

The solution

Together, Shell Brasil, Petrobras, and Sonardyne joined forces with SENAI CIMATEC to develop an advanced seismic data acquisition system under a Brazilian National Agency of Petroleum, Natural Gas and Biofuels (ANP) promoted research and development project.

At its core is an On-Demand Ocean Bottom Node, or OD OBN. This semi-permanent seabed system is used for the acquisition of high resolution seismic and seafloor subsidence data.

Like conventional seabed nodes (OBN), each OD OBN contains three geophones and one hydrophone, a data recording system, batteries and a highly accurate clock. The sensors detect pressure waves emitted by an airgun source, usually towed by a ship, as they are reflected upwards towards the seabed from the underlying layers of rock surrounding the reservoir.

Unlike conventional nodes, these OD OBNs remain on the seabed, down to 3,000 m, gathering seismic data for up to five years. This significantly reduces the cost of repeated ocean bottom seismic campaigns, as the node handling vessel is removed from the operations. It also reduces the impact on the environment and marine ecosystems.

The activation of the nodes, verification of subsidence event alarms, calibration of internal clocks and harvesting of seismic data will be performed using an autonomous underwater vehicle (AUV) called Flatfish developed, in a closely interlinked ANP project, by partners Shell Brasil, Petrobras, SENAI CIMATEC and Saipem.

Flatfish will find each node using Sonardyne’s 6th generation (6G) of acoustic positioning systems. Our acoustics will also support data telemetry with the nodes, for health checks, configuration and acoustic time synchronization. The Flatfish will then hover above each node, in turn. Using an extremely high bandwidth and energy efficient laser-based variant of Sonardyne´s BlueComm optical communications device, it will wirelessly harvest many gigabytes of seismic data in just a few minutes.

This variant uses two rapidly modulated lasers to produce simultaneous bi-directional communications over more than five meters range. It is optimised for peak data transfer performance, with speeds of over 600 megabits per second demonstrated. This makes it excellent for harvesting large amounts of data from seabed nodes.

“Using OD OBN in combination with Flatfish, a 4D seismic campaign in the pre-salt may be executed in a simpler manner, with lower operational cost, lower risk of human exposure and lower environmental impact,” says Jorge Lopez, Manager of Subsurface Technology at Shell Brasil. “On top of this, the nodes also measure seafloor deformation and can continuously monitor for possible subsidence events that may occur during the production of the field.”

The results

In the first phase of the OD OBN project, eight fully functional prototype nodes were built. These comprised of two different concept types and were designed and built by SENAI CIMATEC in Salvador, Bahia together with Sonardyne Brasil.

In 2021, initial tests of seismic data recording were conducted at the Sapinhoá pre-salt field offshore Brazil and interoperability tests between the nodes and the Flatfish AUV were performed in shallow water in Trieste, Italy.

A very intensive laboratory and offshore testing and demonstration program is being conducted over the next 18 months to ensure the OD OBN system meets its operational requirements. This program will increase the maturity of the solution, with tests in pre-salt fields for recording seismic data with the OD OBN prototypes and the communication and data harvesting AUV missions.

In the next phase of the project, starting later in 2022, Shell and Petrobras will sign a new agreement to manufacture 600 nodes and deploy them for three years of reservoir monitoring in a Brazilian pre-salt field.

Maior eficiência, baixo custo de operação, para sísmica em águas profundas através de autonomia submarina

A Shell Brasil, em parceria com a Petrobras, a Sonardyne e o instituto de pesquisa brasileiro SENAI CIMATEC estão trabalhando juntos para trazer uma mudança radical na coleta de dados sísmicos 4D na região do pré-sal em águas profundas do Brasil.

Descubra como estamos colaborando para desenvolver tecnologia autônoma inovadora que tornará o monitoramento desses desafiadores campos em águas profundas mais eficiente, com menos pessoas e menor impacto ambiental.

O desafio

Os dados sísmicos são uma parte essencial da atividade de desenvolvimento de campos offshore, especialmente para apoiar o gerenciamento proativo de reservatórios e a otimização da produção. As técnicas para coletar esses dados evoluíram dramaticamente ao longo das décadas; desde o uso de streamers marinhos para grandes campanhas sísmicas de exploração até o uso rotineiro de veículos operados remotamente (ROV) para implantar nós de fundo oceânico (OBN) para imagens de alta resolução de reservatórios do pré-sal.

No entanto, a coleta de dados sísmicos para imagens de reservatórios do pré-sal continua sendo um trabalho intensivo. Envolve embarcações tripuladas grandes, caras e emissoras de carbono para implantação e recuperação de, normalmente, milhares de nós. Como exemplo, para uma campanha de 10 meses em um dos campos gigantes do pré-sal brasileiro, uma embarcação de manuseio de nós pode emitir cerca de 10.000 toneladas de CO₂. Operações caras e complexas podem reduzir a frequência de levantamentos, inclusive daqueles feitos para coletar o lapso temporal que é chamado de dados sísmicos 4D, necessários para monitorar os reservatórios do pré-sal.

A Shell e a Petrobras nos procuraram acreditando que poderia haver uma forma mais barata e sustentável de adquirir dados sísmicos 4D, além de outros parâmetros, como subsidência do fundo do mar, para ajudar a monitorar melhor os reservatórios. Eles também viram que isso poderia ser feito com um impacto ambiental menor e mantendo mais pessoas seguras.

A solução

Juntos, Shell Brasil, Petrobras e Sonardyne uniram forças com o SENAI CIMATEC para desenvolver um sistema avançado de aquisição de dados sísmicos em um projeto de pesquisa e desenvolvimento promovido pela Agência Nacional do Petróleo, Gás Natural e Biocombustíveis (ANP).

Em seu núcleo está um On-Demand Ocean Bottom Node, ou OD OBN. Este sistema semipermanente do fundo do mar é usado para a aquisição de dados sísmicos de alta resolução e subsidência do fundo do mar.

Assim como os nós convencionais do fundo do mar (OBN), cada OD OBN contém três geofones e um hidrofone, um sistema de gravação de dados, baterias e um relógio de alta precisão. Os sensores detectam ondas de pressão emitidas por uma fonte do tipo airgun, rebocada por um navio, à medida que são refletidas para cima em direção ao fundo do mar a partir das camadas subjacentes de rocha ao redor do reservatório.

Ao contrário dos nós convencionais, os OD OBNs permanecem no fundo do mar, até 3.000 m, coletando dados sísmicos por até cinco anos. Isso reduz significativamente o custo de repetidas campanhas sísmicas no fundo do oceano, uma vez que a embarcação de manuseio de nós é removida das operações. Também reduz o impacto no meio ambiente e nos ecossistemas marinhos.

A ativação dos nós, a verificação dos alarmes dos eventos de subsidência, a calibração dos relógios internos e a coleta dos dados sísmicos serão realizados por meio de um veículo submarino autônomo (AUV) denominado Flatfish, desenvolvido em um projeto ANP estreitamente interligado, pelos parceiros Shell Brasil, Petrobras, SENAI CIMATEC e Saipem.

O Flatfish encontrará cada nó usando a 6ª geração (6G) de sistemas de posicionamento acústico da Sonardyne. Nossa acústica também suportará telemetria de dados com os nós, para verificações de integridade, configuração e sincronização de tempo acústico. O Flatfish irá então pairar acima de cada nó, por sua vez. Usando uma largura de banda extremamente alta e uma variante baseada em laser com eficiência energética do dispositivo de comunicação óptica BlueComm da Sonardyne, ele coletará sem fio muitos gigabytes de dados sísmicos em apenas alguns minutos.

Esta variante usa dois lasers modulados rapidamente para produzir comunicações bidirecionais simultâneas em um alcance de mais de cinco metros. Ele é otimizado para desempenho de transferência de dados de pico, com velocidades demonstradas de mais de 600 megabits por segundo. Isso o torna excelente para coletar grandes quantidades de dados de nós do fundo do mar.

“Usando OD OBN em combinação com o Flatfish, uma campanha sísmica 4D no pré-sal pode ser executada de forma mais simples, com menor custo operacional, menor risco de exposição humana e menor impacto ambiental”, afirma Jorge Lopez, Gerente de Tecnologia de Subsuperfície da Shell Brasil. “Além disso, os nós também medem a deformação do fundo do mar e podem monitorar continuamente possíveis eventos de subsidência que podem ocorrer durante a produção do campo”.

Os resultados

Na primeira fase do projeto OD OBN, doze nós protótipos totalmente funcionais foram construídos. Estes são compostos por dois tipos de conceito diferentes e foram projetados e construídos pelo SENAI CIMATEC em Salvador, Bahia em conjunto com a Sonardyne Brasil.

Em 2021, os testes iniciais de registro de dados sísmicos foram realizados no campo do pré-sal de Sapinhoá no litoral brasileiro e os testes de interoperabilidade entre os nós e o Flatfish AUV foram realizados em águas rasas em Trieste, Itália.

Um intenso trabalho em laboratório e um programa de demonstração e testes offshore estará sendo realizado nos próximos 18 meses para garantir que o sistema OD OBN atenda aos seus requisitos operacionais. Este programa aumentará a maturidade da solução, com testes em campos do pré-sal para registro de dados sísmicos com os protótipos OD OBN e as missões AUV de comunicação e coleta de dados.

Na próxima fase do projeto, a partir do final de 2022, a Shell e a Petrobras assinarão um novo acordo para fabricar 600 nós e implantá-los para três anos de monitoramento de reservatórios num campo do pré-sal brasileiro.

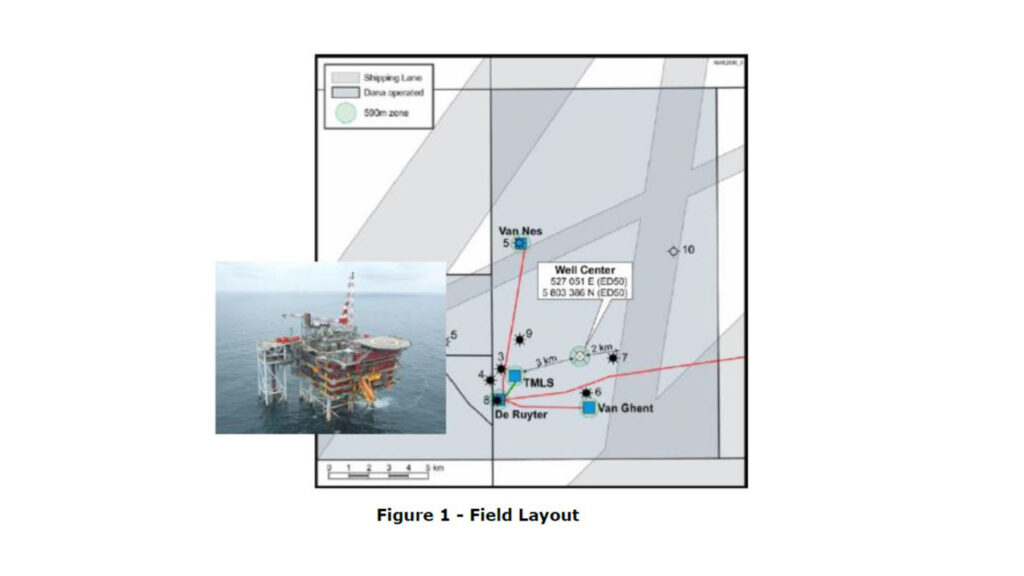

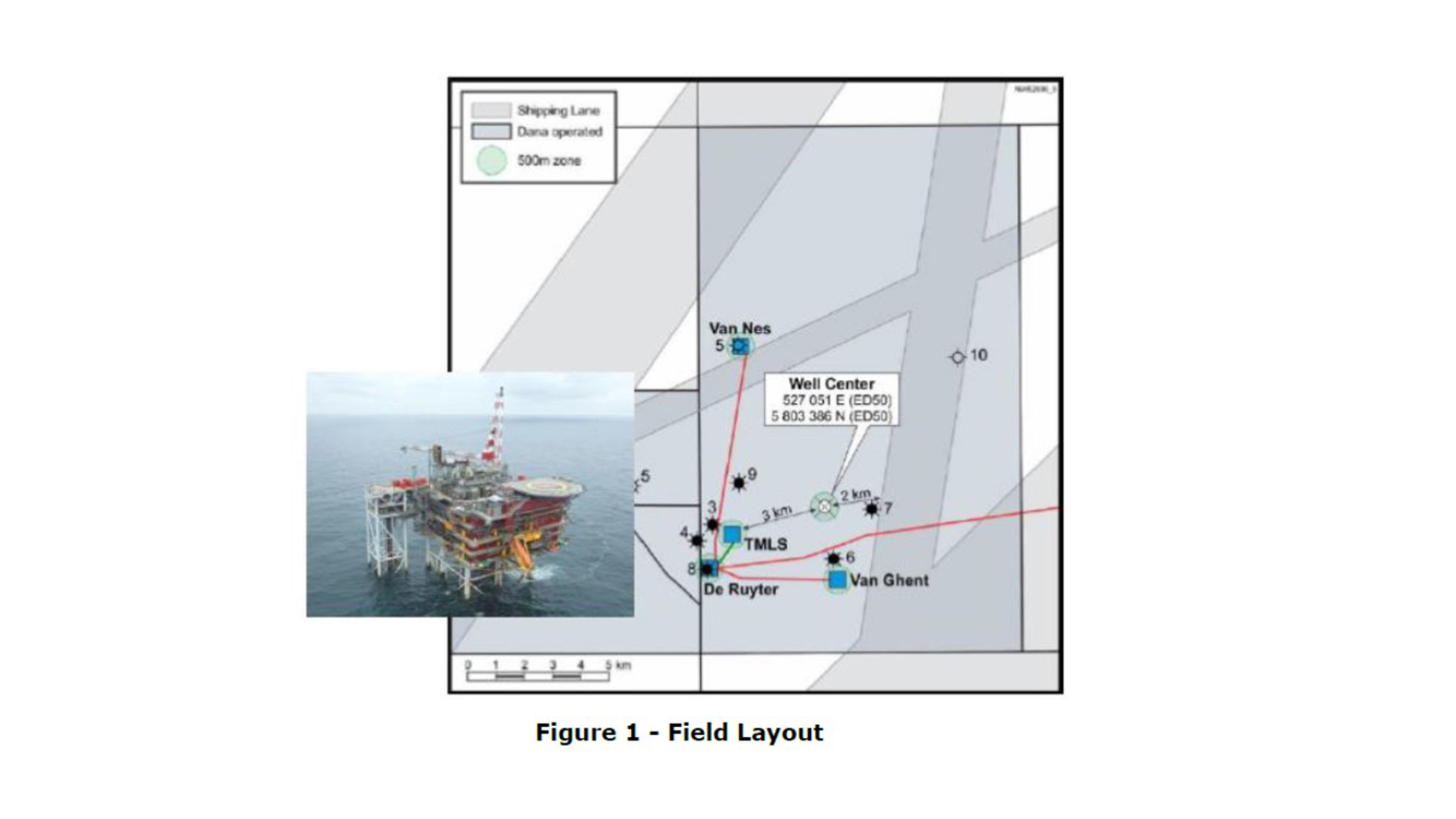

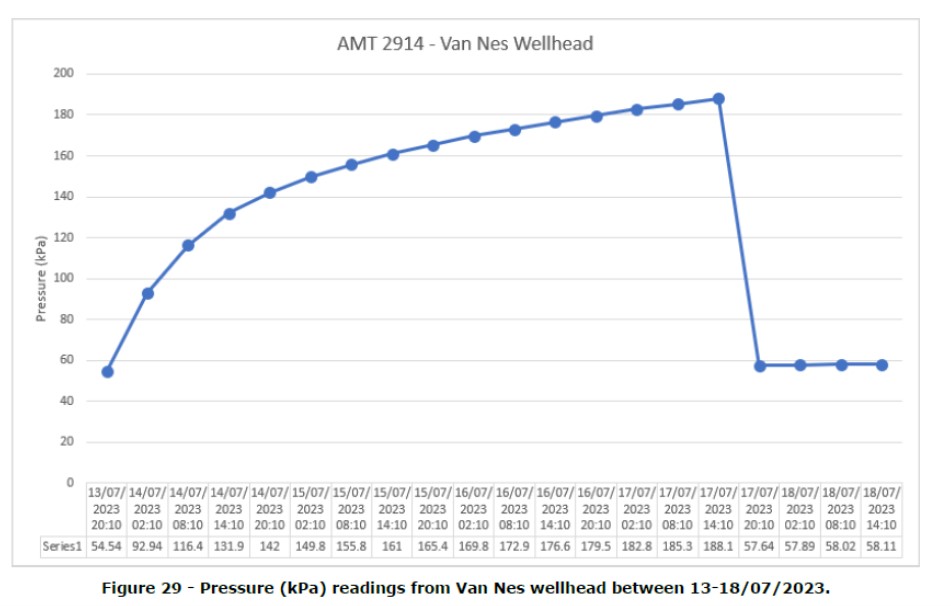

A 'custom-off-the-shelf' product provides a timely solution for Dana Petroleum

Our experience and expertise allowed us to rapidly adapt our off-the-shelf technology for Dana Petroleum. This delivered a cost-efficient, low environmental impact, and timely solution for them to monitor their suspended wells in the North Sea.

The challenge

As they reach the end of their productive life, oil and gas well heads still need to be monitored whilst suspended – for up to five years, before they become fully abandoned / decommissioned. A regime must be in place to monitor the assets ‘in perpetuity’ to meet government regulations. As this is ‘abandonment expenditure’, rather than capital expenditure, any monitoring schedule must be conducted as cost effectively as possible.

Dana Petroleum (Netherlands) was faced with one such challenge in early 2023 when they needed to plan and implement a well annulus monitoring schedule for suspended wells at their Van Ghent and Van Nes subsea wells, situated in the North Sea approximately 60km West of The Hague. The wells were situated alongside others still in operation and although the topside platform remained, communication links with the sensors on the suspended subsea wells had been lost. There was an additional challenge of the system needing to be in place within 12 weeks.

The solution

The ’simple’ solution would have been to lay new communication cables from the suspended well heads to the topside platform to enable the monitoring. But this would have been lengthy, expensive and carbon intensive, involving bringing in large vessels to lay long stretches of subsea cables. A quicker, cost effective and lower carbon solution was needed. Having heard about Sonardyne’s experience and expertise in long-term subsea asset monitoring, Dana Petroleum approached us for a solution.

We have many years’ experience in providing subsea pressure and temperature data directly from well downhole gauges, mostly during the appraisal phase in a field development, providing essential data to the reservoir engineers before connection is made to the offshore or onshore facility.

Although Dana Petroleum’s requirement was well within our capabilities, there were some initial unknowns such as; field layout, pressure gauge model and manufacturer and how the equipment would be mounted to the subsea manifold. Also, which topside would be most suitable for data harvest? Something which is typically dictated by the vessel size, noise profile and water depth. The timeframe was also very challenging.

In the following weeks, Dana Petroleum provided information on the field layout, drawings of the subsea infrastructure and a strong specification for a system capable of monitoring the annulus pressures at both locations. Having received this, we were able to provide illustrations of previously designed bracketry, 3D CAD images of our potential offering and expert advice to work out the optimum placement to enable best line of site for data harvesting. With a firm specification and known time constraints we looked to our off-the-shelf products with a view to creating a semi-custom solution with our projects team.

The obvious choice was to make custom alterations to our Autonomous monitoring transponder (AMT). The AMT has been used in a wide variety of different applications including overburden monitoring and pipeline movement monitoring, all utilising and autonomously logging pressure sensor data. These solutions can operate autonomously over long periods of time, over five years – depending on deployment – logging data and making it accessible for wireless upload.

The topside platform of choice was a Nano topside equipped with a ruggedised laptop running Sonardyne’s Monitor software fitted to a small crew transfer vessel that would pass by the wells at regular intervals, delivering workers to the platforms. The size of the vessel dictated a small portable solution but other options are available for all sizes of vessels.

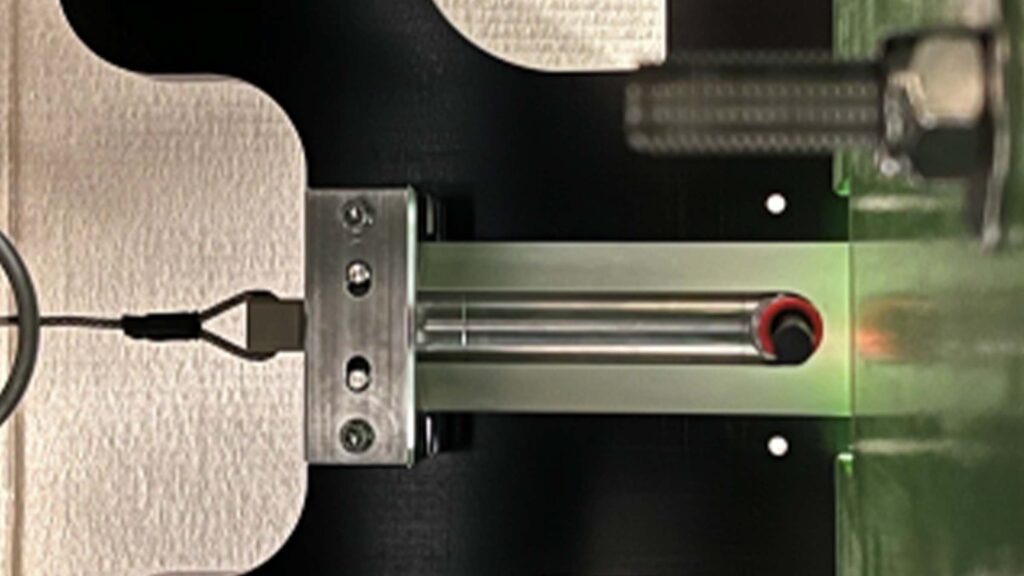

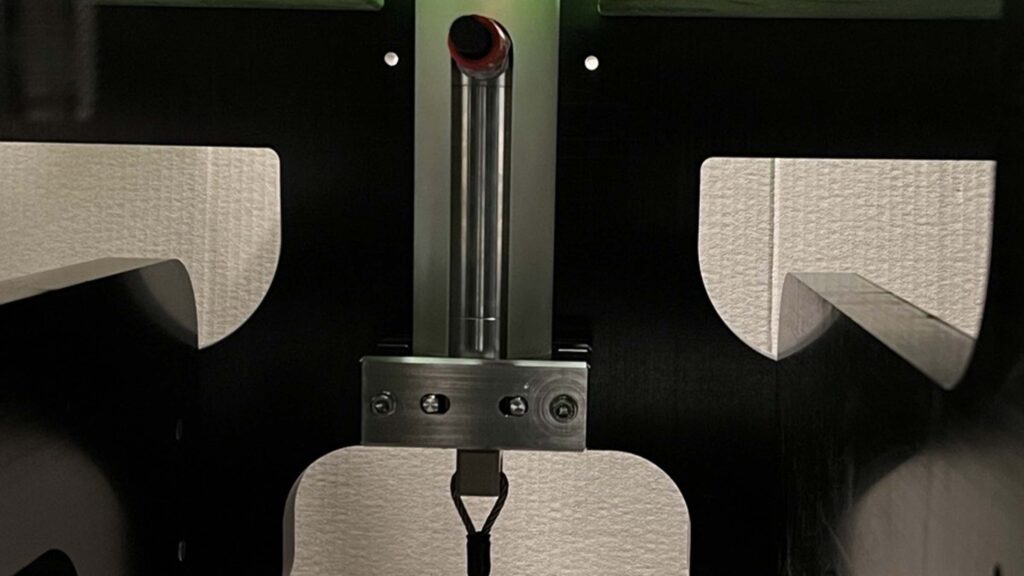

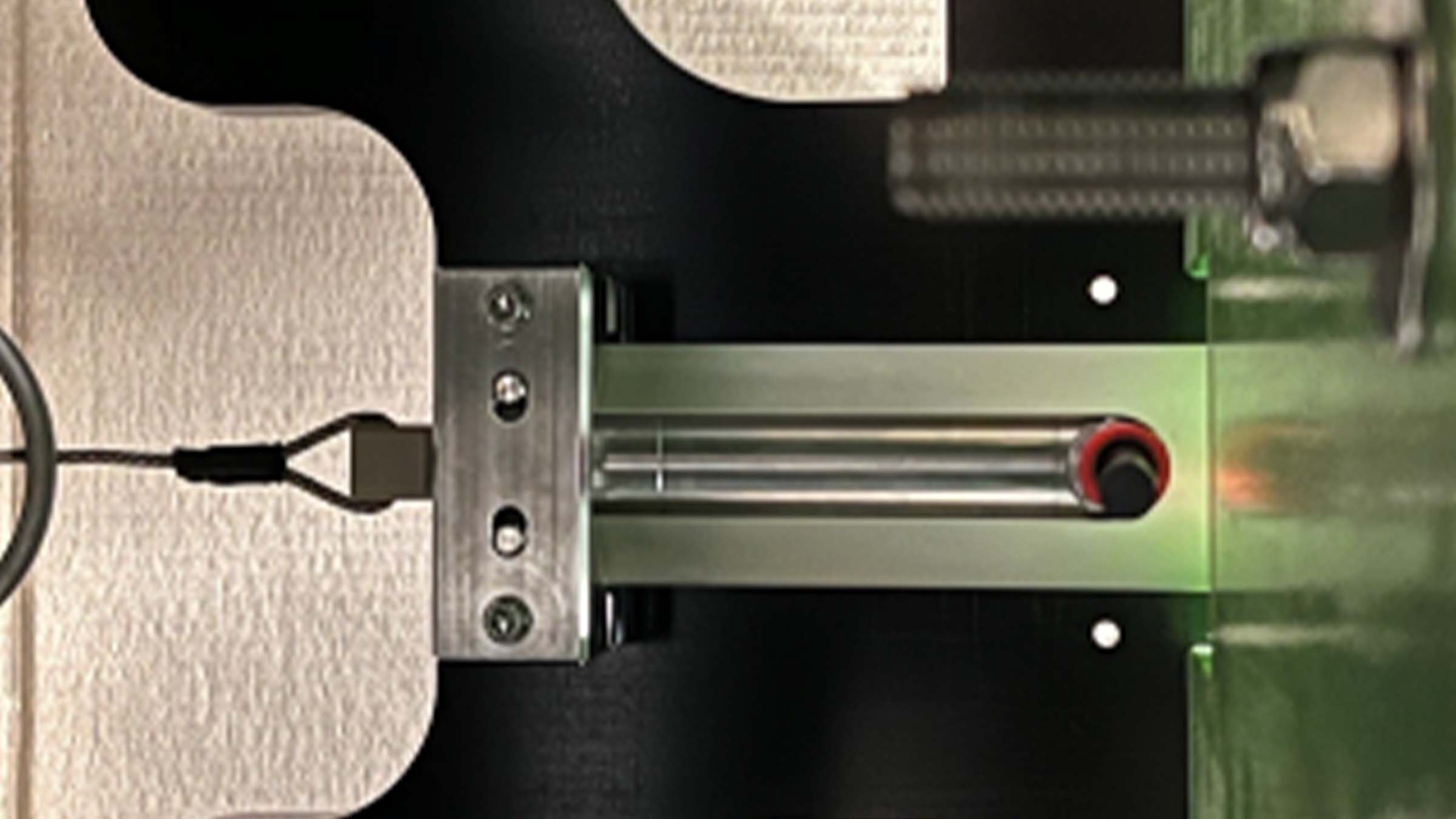

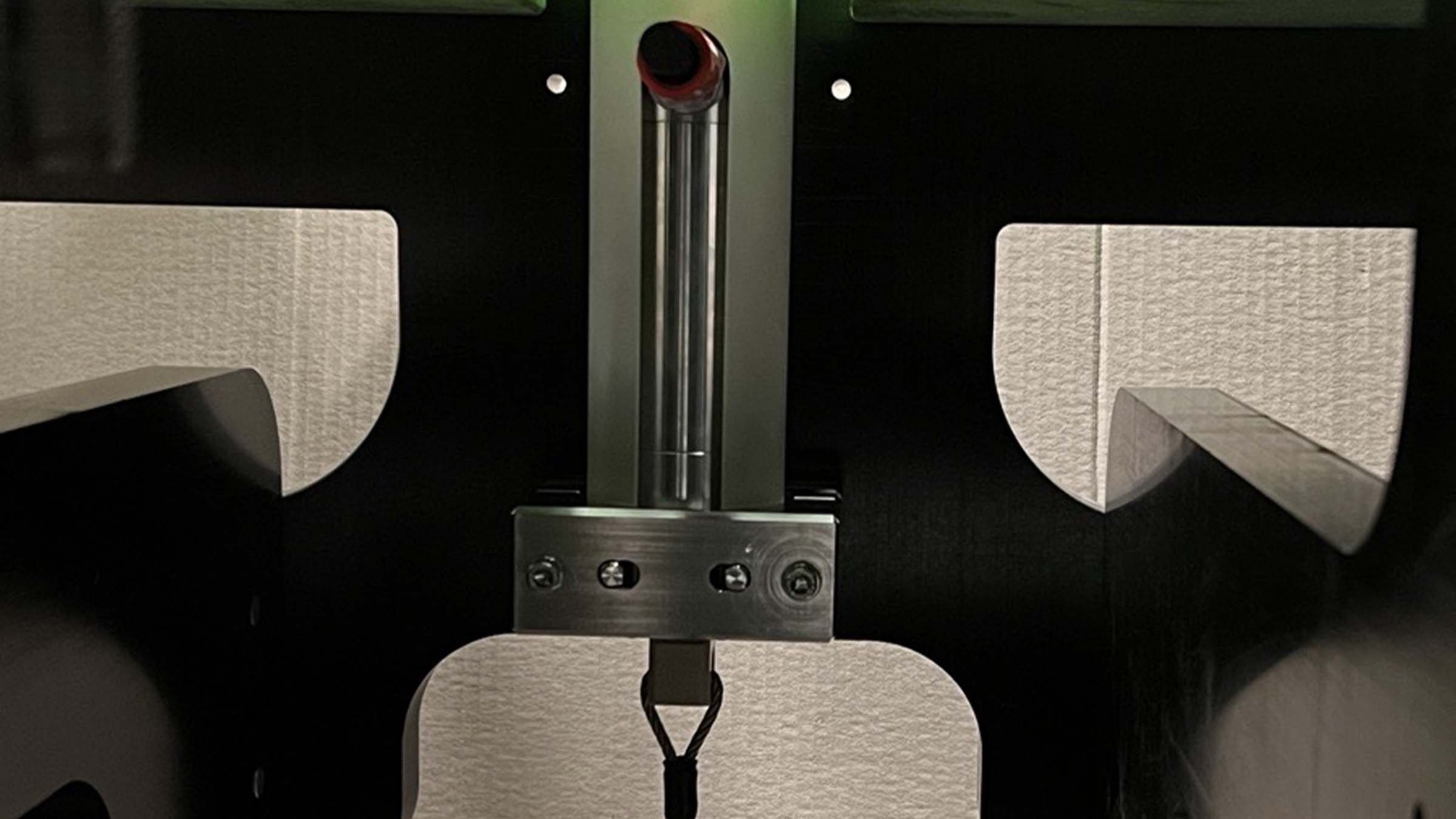

Once the seabed and topside products were selected, custom modifications were made by the projects team to the AMT, allowing the pressure sensor to be connected to the annulus via a flange – rather than inside the AMT –to give flexibility in the location of the AMT and achieve best line of communication with the Nano transceiver when it passed overhead.

A factory acceptance test was witnessed by Dana Petroleum where our projects team provided documentation and coordinated the testing. Following this the equipment was shipped and ready for installation – all within a few months!

Transponders provide reliable releases for Allton offshore Norway

When placing vital equipment such as Nodes on the seabed you need to be sure that you can retrieve them. During the development process, a lack of other products available in the marketplace that met their requirements led Norwegian technology and service company Allton to turn to Sonardyne for a solution.

Starting life as Petromarker in 2005, Allton has been operating offshore Norway for almost 20 years. The company specialises in: marine subsurface electro-magnetic (EM) data acquisition and imaging for hydrocarbon exploration and production, CO2 measurement, monitoring and verification for carbon capture sequestration and marine mineral exploration. It has now expanded its technology and service offering to include multiphysics joint acquisition of both EM and seismic OBN data.

With their innovative multiphysics platform relying on the data they retrieve from both EM and seismic OBN nodes, Allton need to be one hundred percent confident that they can locate and recover their nodes once they’ve been deployed. This can be from depths of up to 3,500 m in often challenging conditions.

When Allton expanded its operational work department and began the redesign of its subsea equipment, a search began for new and reliable solutions as existing transponders and release mechanisms were unsuitable for their specific requirements.

With several decades of subsea transponder and release manufacturing experience, Sonardyne was an obvious choice for a solution.

Our RT 6 family of acoustic release transponders combine the extensive track record of our previous models with the flexibility of a 6G hardware platform, meaning they can be deployed, located and released using any of our Ranger 2 USBL systems or 6G topsides.

An acoustic release transponder is fixed to a subsea asset so it can be found and recovered. An acoustic signal from a surface vessel locates the transponder on the asset. A second acoustic signal then tells the transponder to release the mechanism anchoring the asset to the seabed so that it can be retrieved.

Having gained a full understanding of Allton’s requirements, our engineering team worked closely with them to custom modify an existing RT 6 model to meet their exact needs. Aleksander Kristiansen, Supply Chain and Asset Manager, from Allton explains, “The custom manufacture of our RT 6-4000 was based on an existing model (RT 6-1000) which Sonardyne modified to suit our operational needs. This included extending its range and adding a secondary burn release circuit.

Working with our customers to fully appreciate their needs and the challenges their businesses face enables us to develop solutions for their specific operations. As Trevor Barnes, Sonardyne Sales Manager, explains: “Allton was looking for a robust, reliable acoustic release to give them confidence in retrieving their equipment from a range of depths. Whilst our RT 6-1000 is perfect for depths of up to 1,000 m, Allton operate in depths of up to 3,500 m so our engineers worked closely with them to develop an RT 6-4000 to enable this. A secondary burn-wire release was also added at their request, as a backup in the unlikely event that the first acoustic release fails.”

Aleksander Kristiansen continued “Sonardyne were always willing to assist and put the right technical expertise onto the variety and wide range of tasks to solve our many, often complex at times, challenges. Their creative ideas were well aligned with our expectations and letting us borrow equipment for an extensive time to conduct in-house testing was much appreciated. It gave us further confirmation that we were making the right choice in the RT 6 releases.”

Allton’s nodes are now fitted with RT 6-4000 acoustic releases to ensure that they can be reliably located and retrieved from the seabed at all their operating depths and in any conditions.

They can now provide data across all of their services with confidence that they have consistent, reliable access to their network of nodes.

Our standard RT 6s come in three depth ratings, 1,000 m, 3,000 m and 6,000 m and all use our workhorse Ranger 2 USBL system or deck topside to command and track. Some models can even be controlled using an Android app.

If you have a similar operational challenge, take the worry out of mooring and retrieving your kit and talk to us today.