A 'custom-off-the-shelf' product provides a timely solution for Dana Petroleum

Our experience and expertise allowed us to rapidly adapt our off-the-shelf technology for Dana Petroleum. This delivered a cost-efficient, low environmental impact, and timely solution for them to monitor their suspended wells in the North Sea.

The challenge

As they reach the end of their productive life, oil and gas well heads still need to be monitored whilst suspended – for up to five years, before they become fully abandoned / decommissioned. A regime must be in place to monitor the assets ‘in perpetuity’ to meet government regulations. As this is ‘abandonment expenditure’, rather than capital expenditure, any monitoring schedule must be conducted as cost effectively as possible.

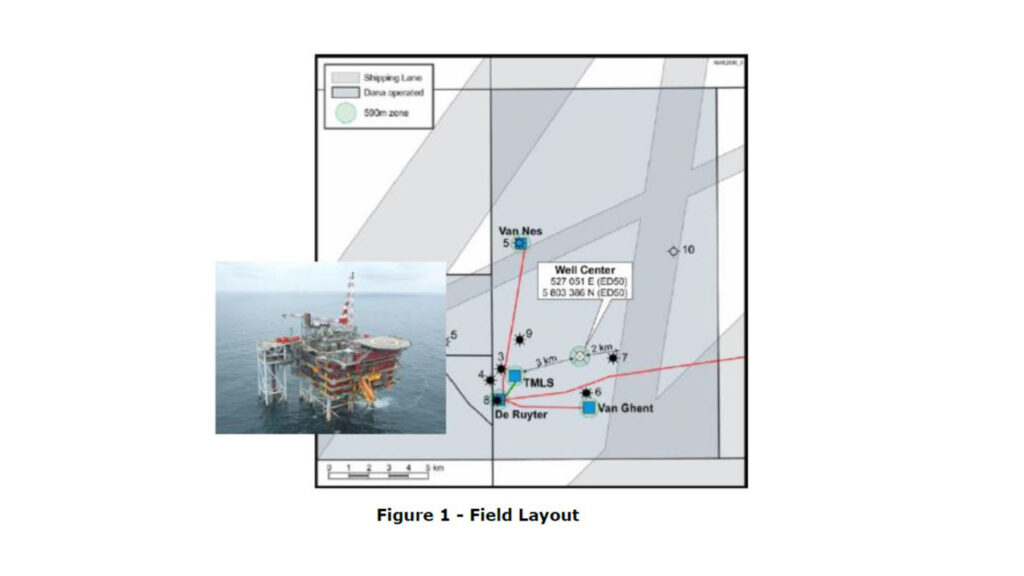

Dana Petroleum (Netherlands) was faced with one such challenge in early 2023 when they needed to plan and implement a well annulus monitoring schedule for suspended wells at their Van Ghent and Van Nes subsea wells, situated in the North Sea approximately 60km West of The Hague. The wells were situated alongside others still in operation and although the topside platform remained, communication links with the sensors on the suspended subsea wells had been lost. There was an additional challenge of the system needing to be in place within 12 weeks.

The solution

The ’simple’ solution would have been to lay new communication cables from the suspended well heads to the topside platform to enable the monitoring. But this would have been lengthy, expensive and carbon intensive, involving bringing in large vessels to lay long stretches of subsea cables. A quicker, cost effective and lower carbon solution was needed. Having heard about Sonardyne’s experience and expertise in long-term subsea asset monitoring, Dana Petroleum approached us for a solution.

We have many years’ experience in providing subsea pressure and temperature data directly from well downhole gauges, mostly during the appraisal phase in a field development, providing essential data to the reservoir engineers before connection is made to the offshore or onshore facility.

Although Dana Petroleum’s requirement was well within our capabilities, there were some initial unknowns such as; field layout, pressure gauge model and manufacturer and how the equipment would be mounted to the subsea manifold. Also, which topside would be most suitable for data harvest? Something which is typically dictated by the vessel size, noise profile and water depth. The timeframe was also very challenging.

In the following weeks, Dana Petroleum provided information on the field layout, drawings of the subsea infrastructure and a strong specification for a system capable of monitoring the annulus pressures at both locations. Having received this, we were able to provide illustrations of previously designed bracketry, 3D CAD images of our potential offering and expert advice to work out the optimum placement to enable best line of site for data harvesting. With a firm specification and known time constraints we looked to our off-the-shelf products with a view to creating a semi-custom solution with our projects team.

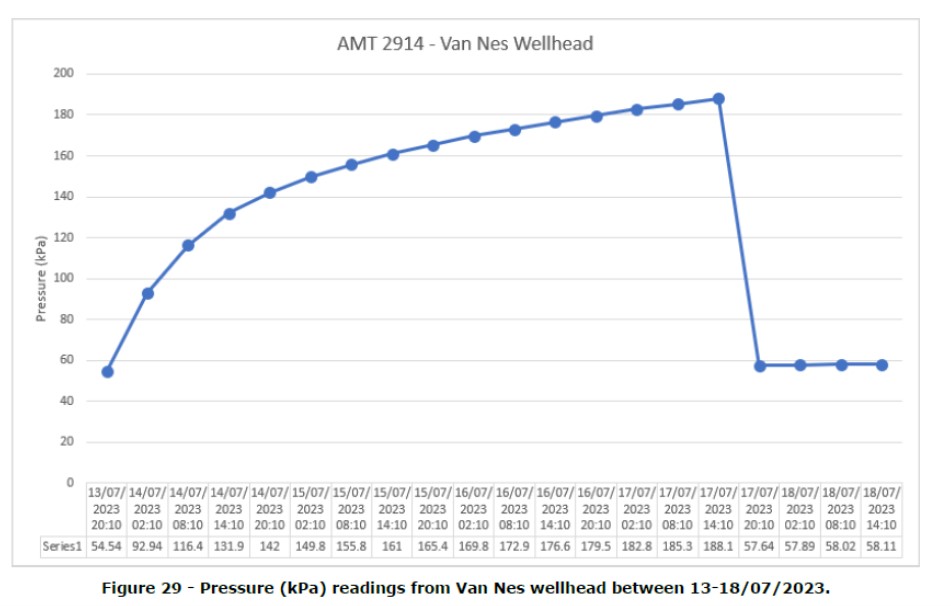

The obvious choice was to make custom alterations to our Autonomous monitoring transponder (AMT). The AMT has been used in a wide variety of different applications including overburden monitoring and pipeline movement monitoring, all utilising and autonomously logging pressure sensor data. These solutions can operate autonomously over long periods of time, over five years – depending on deployment – logging data and making it accessible for wireless upload.

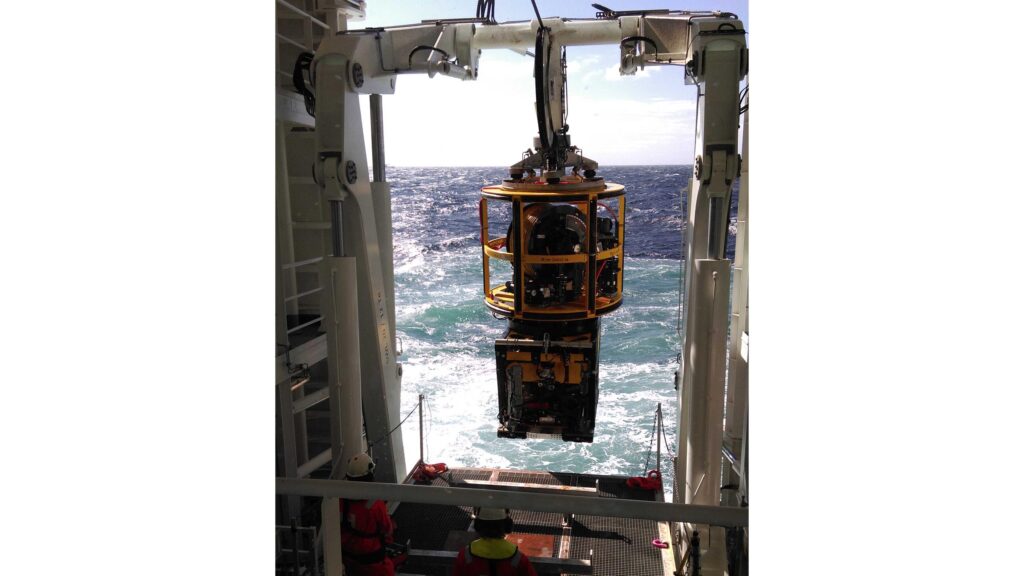

The topside platform of choice was a Nano topside equipped with a ruggedised laptop running Sonardyne’s Monitor software fitted to a small crew transfer vessel that would pass by the wells at regular intervals, delivering workers to the platforms. The size of the vessel dictated a small portable solution but other options are available for all sizes of vessels.

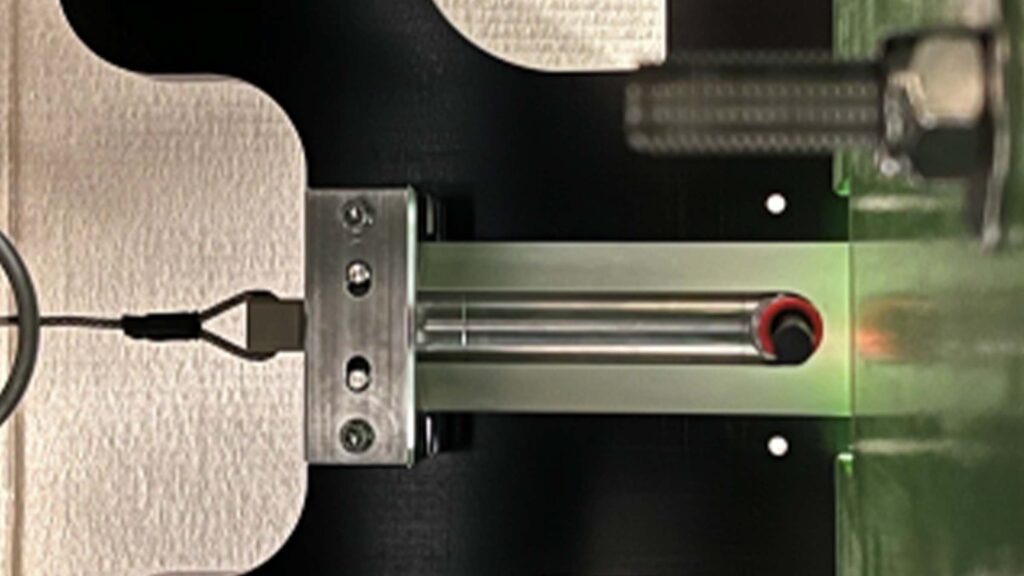

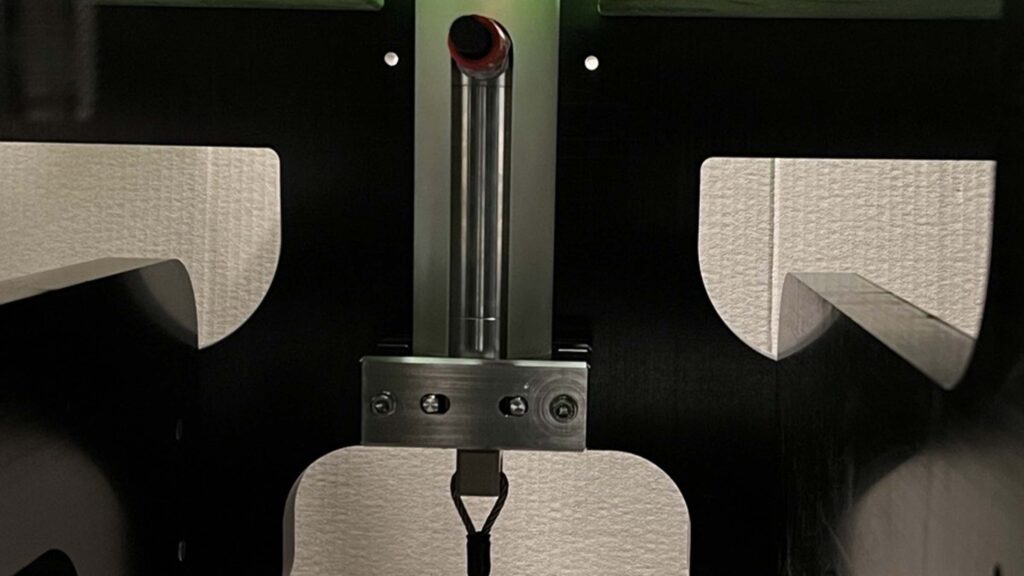

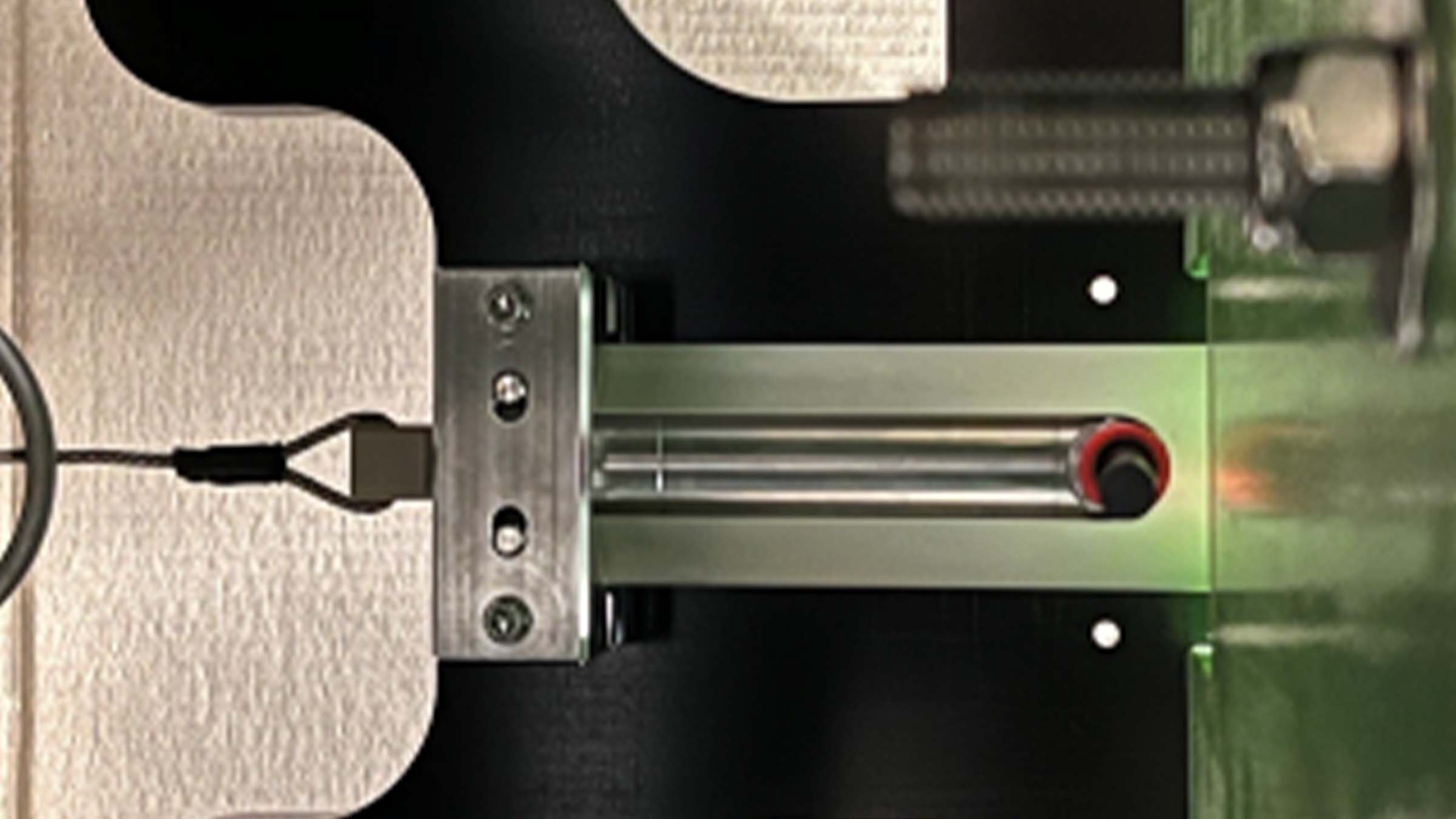

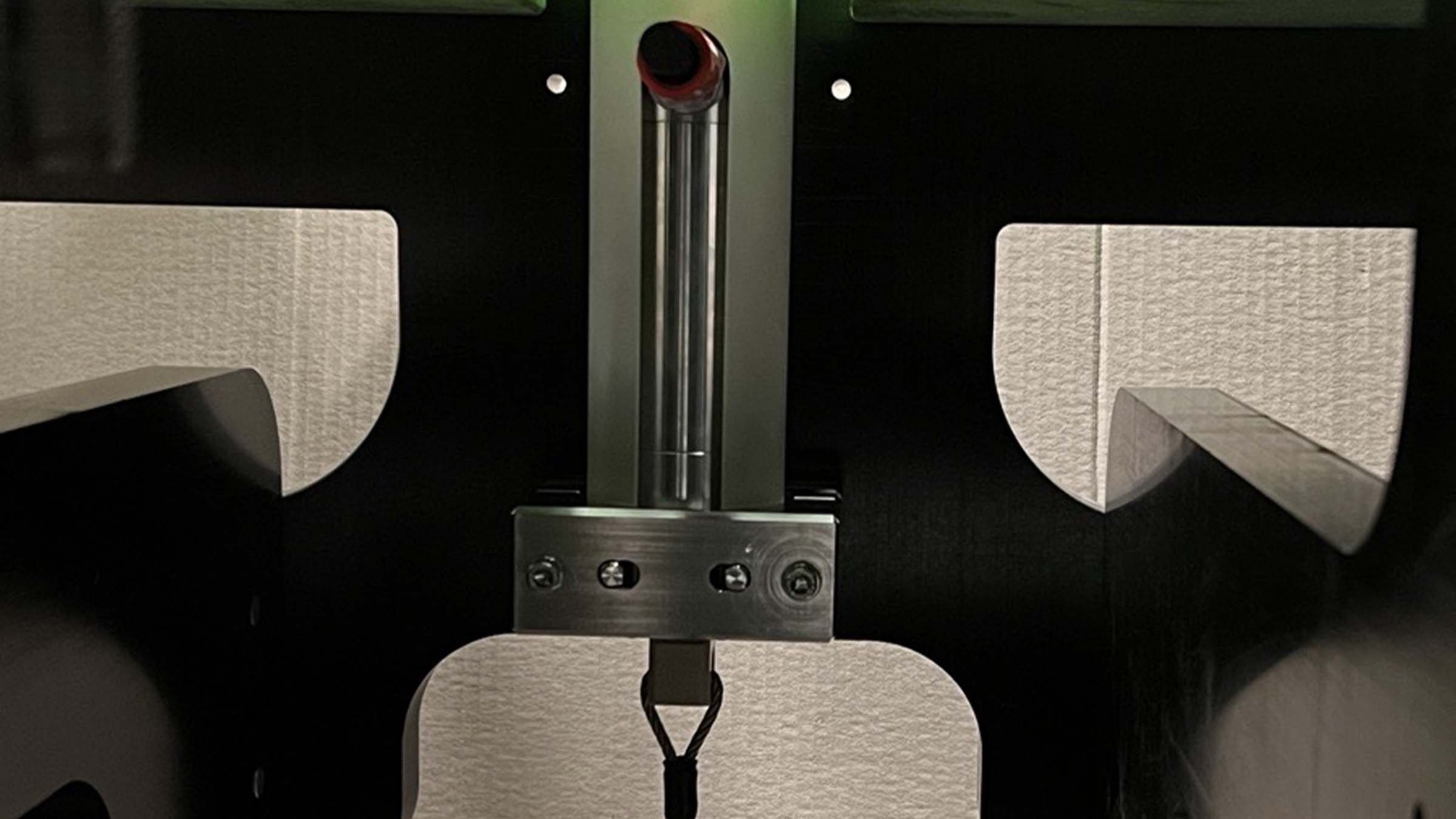

Once the seabed and topside products were selected, custom modifications were made by the projects team to the AMT, allowing the pressure sensor to be connected to the annulus via a flange – rather than inside the AMT –to give flexibility in the location of the AMT and achieve best line of communication with the Nano transceiver when it passed overhead.

A factory acceptance test was witnessed by Dana Petroleum where our projects team provided documentation and coordinated the testing. Following this the equipment was shipped and ready for installation – all within a few months!

Over the horizon robotic data harvest aids Shell's net zero ambition

Sonardyne, working with XOCEAN’s Uncrewed Surface Vehicles (USV), deliver a lower cost, lower risk and lower carbon, remote acoustic data harvesting service to Shell from their Ormen Lange gas field in the Norwegian Sea.

Shell’s Ormen Lange gas field is a deep-sea site 120 km / 75 miles off the coast of Norway. As Norway’s second largest gas producer, it plays a key role delivering stable gas supplies to Europe. Built on the site close to Storegga, a major landslide which occurred some 8000 years ago, about 5 million tonnes of rock was used to prepare the seabed for subsea equipment back in 2005. The field has been operational since 2007. Ormen Lange is distinctive in that it doesn’t have conventional surface operation platforms.

Close monitoring of any seabed movement is key to prevent any potential impact to the pipe system. Monitoring of the ocean floor around the well heads is conducted by seabed sensors. The first monitoring array at the site saw 203 Acoustic Monitoring Transponders (AMTs) installed in 2011. These sensors enabled monitoring of changes in pressure and tilt to provide an understanding of seabed movement.

This array was recovered in 2016 due to battery limitations and uncertainty in drift. Today the monitoring is undertaken by an array of 75 Sonardyne seabed Pressure Monitoring Transponders (PMTs). Shell took the decision to install 30 PMTs in 2019 with a further 45 installed in 2020.

The challenge

Without surface platforms, acoustic data from the subsea sensors had to be harvested by crewed vessels in the early years of the field’s operation. This was costly, carbon heavy and posed a risk to personnel in often challenging sea conditions.

With a company ‘Powering Progress’ strategy to achieve net-zero emissions by 2050, Shell was looking for an alternative data harvest method that would reduce cost and risk as well as its carbon footprint.

The solution

Marine robotic platforms provide the opportunity to remove carbon and personnel risk. Working with the customer and XOCEAN as a sub-contractor we developed a solution that would save time, costs. and carbon, while also eliminating the human risk element, using a USV to conduct the data harvest.

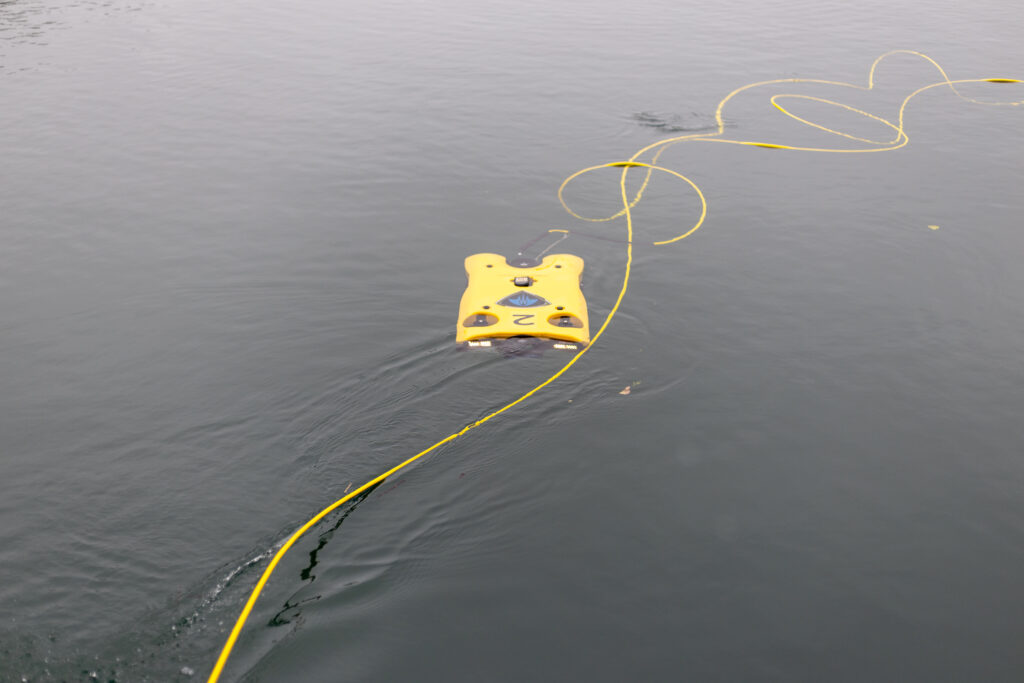

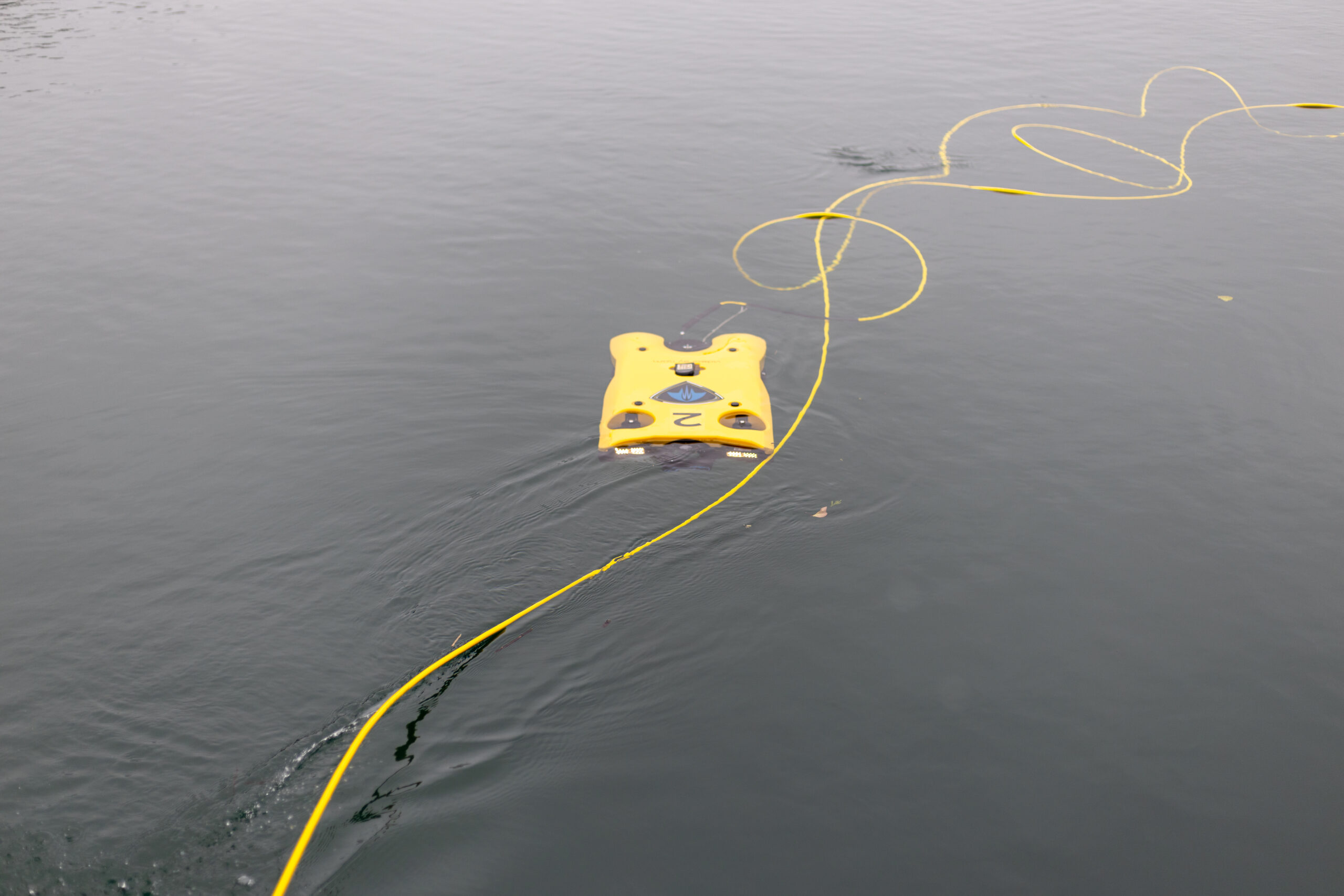

The proposal was to use our HPT 3000 transceiver mounted to an XOCEAN USV to remotely harvest data from the 75 seabed PMTs. The HPT 3000 is perfect in terms of size, weight and power for deployment from a USV and can communicate with seabed transponders at depths up to 995 m (or 4000 m with an extended range version).

XOCEAN USVs are perfect for the data harvesting mission at Ormen Lange. They enable full over-the-horizon 24/7 operations. This means that operators and data analysts can remain safely onshore whilst the operation takes place and data can be sent ashore and verified in near real-time using the USV’s satellite communications.

This satisfied Shell’s commitment to accelerate the transition of their business to net-zero emissions and to integrate sustainability within their business strategy. Following the successful PMT installation in 2019, a five year project was agreed where Sonardyne are responsible for the data delivery to Shell and XOCEAN are responsible for delivering the transceiver to the field for data collection via their USV.

The results

The project began in January 2020 and this was the first time a remote USV data harvest was completed offshore in Norwegian waters by any operator.

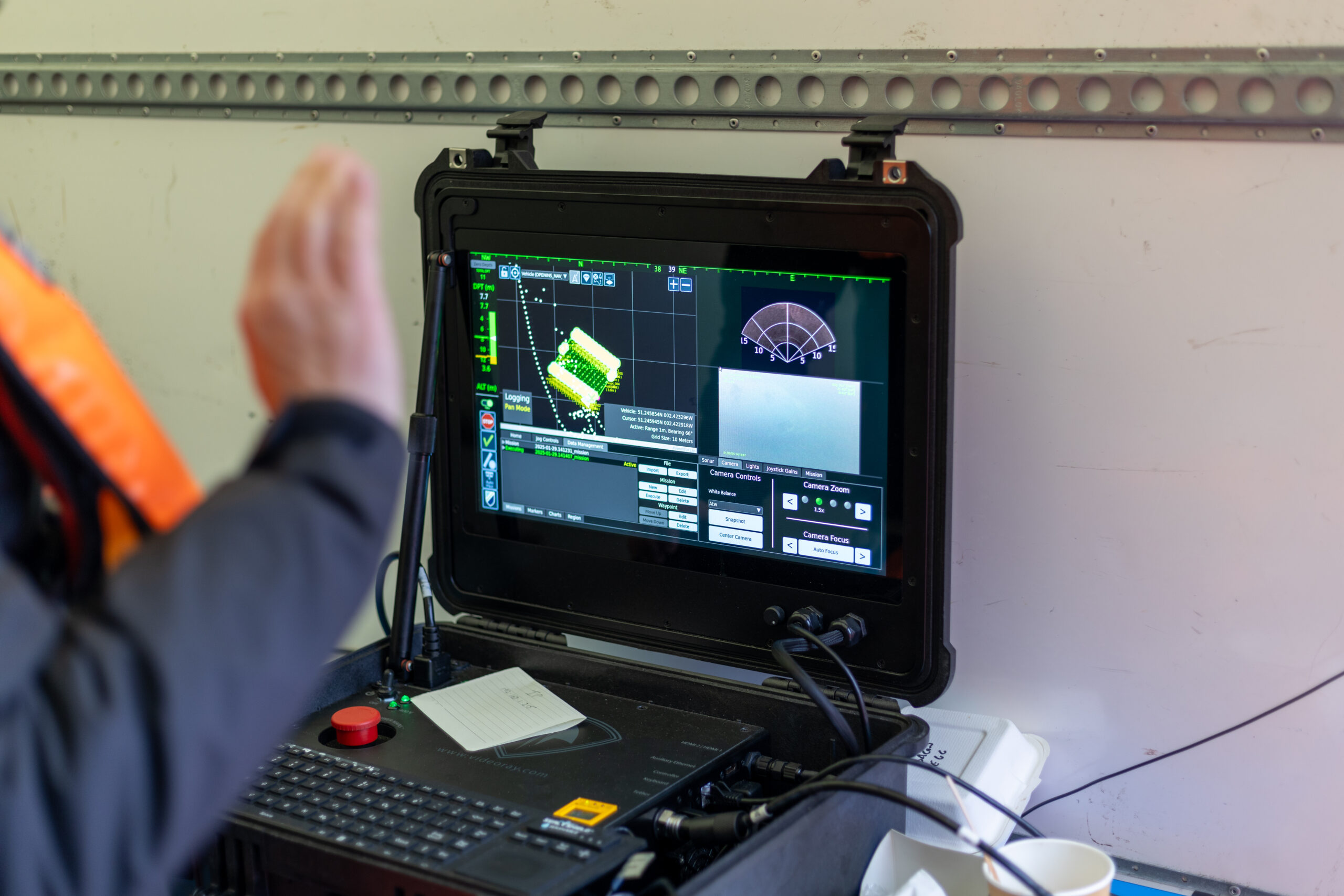

Whilst the USV and HPT 3000 were in Norwegian waters surveying the Ormen Lange site, the Sonardyne and XOCEAN personnel never left their bases in England and Ireland.

The data harvest was monitored in real time, 24/7 and the two teams were in contact with each other as well as the remote equipment. This mean that data was being monitored by our team as it was collected and there was no risk of the USV returning with missing or irrelevant data. Had there been any missed or partially collected data the Sonardyne team could ask the XOCEAN team to return to recollect from a particular PMT whilst still in the field, rather than waiting until the vessel returned and having to send it out again.

Successful data harvests have been conducted yearly since 2020 and continue to be a cost effective, low impact operation. This year we collected data from the Ormen Lange site twice, in Spring and Autumn.

If you think you have a similar challenge for us, contact us today.

Facing the challenge of speeding up consent in offshore renewable energy

The drive for cleaner, greener energy set against financial constraints in a challenging world market could mean testing times ahead for offshore renewable energy (ORE).

In order to meet pressing timescales, cost saving criteria and governmental targets for energy production, the industry needs shorter consenting periods for offshore wind projects but also better characterisation data. Better data would suggest the need for a longer, more costly, consenting period. So how can this challenge be met?

At Sonardyne, we believe our Origin® acoustic Doppler current profilers (ADCPs) may offer at least part of the solution. ADCPs use acoustics to measure the water column to determine currents and many can also measure wave motion and turbulence. They can provide metocean data for decision making on where to place floating turbines to ensure moorings are not stressed, determining where scour may occur that will damage cables or structures, array cable selection, route planning and cable’s depth of burial predictions etc.

Obtaining high quality, accurate, current and wave data has always been a challenge in the marine environment. Which is far from ideal when there’s a need for more timely, precise data. Meanwhile, traditional ADCP technology does not have resolution high enough to distinguish fine-scale turbulence. The correct measurement of turbulence is a key factor in ensuring that any planning at the consenting stage is based on accurate data.

With accurate data at the consenting stage, developers can reduce options and decide on the exact foundation solution, maximum turbine size etc. They can then plan with certainty and model simple environmental impact assessments for presentation to the consenting authorities.

Enter Origin…

Our Origin 600 and 65 ADCPs signify a sea change in ocean floor ADCP technology and are the most advanced ADCP’s presently on the market.

Alongside industry standard PD0, new and exclusive A-gram and B-gram proprietary data formats offer up to ten times greater spatial resolution and provide superior quality data for more informed decision making.

The inbuilt acoustic modem provides the ability to; check operating status, test data quality and change schedules mid-mission. It also provides remote access to the customisable Edge data processing applications on Origin. This means that while the device is deployed, it can be programmed to output concise, relevant information, rather than bulky raw data that would normally be processed once the device is recovered from the water. All without the cost and risk associated with interfacing an external modem or running a cabled ADCP operation.

Realising the potential

Taking this a step further and combining Origin’s data and communication capabilities with autonomous data collection via an uncrewed surface vehicle (USV) or surface buoy potentially offers many advantages.

Operators can make informed decisions faster as more frequent, concise data samples can be collected throughout the deployment, rather than waiting for the ADCP’s retrieval. Data can be collected at intervals via a USV passing overhead or transmitted to Cloud storage via a LiDAR buoy.

Reduction of carbon emissions during missions can also be achieved. USV data harvesting and an ADCP battery life of over three months are just two in which the need for a carbon-heavy crewed vessel would be reduced. The associated costs and HSE exposure hours would be reduced too.

Origin’s ability to provide high fidelity data, often in near real-time – depending on the harvesting method – offers the potential to meet the data requirements within a shorter timeframe.

Concept testing

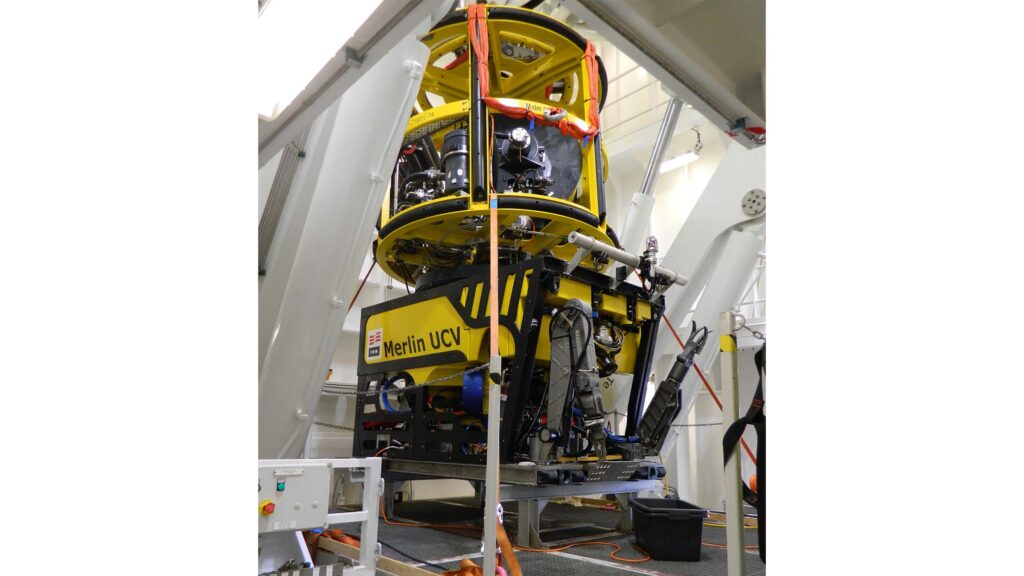

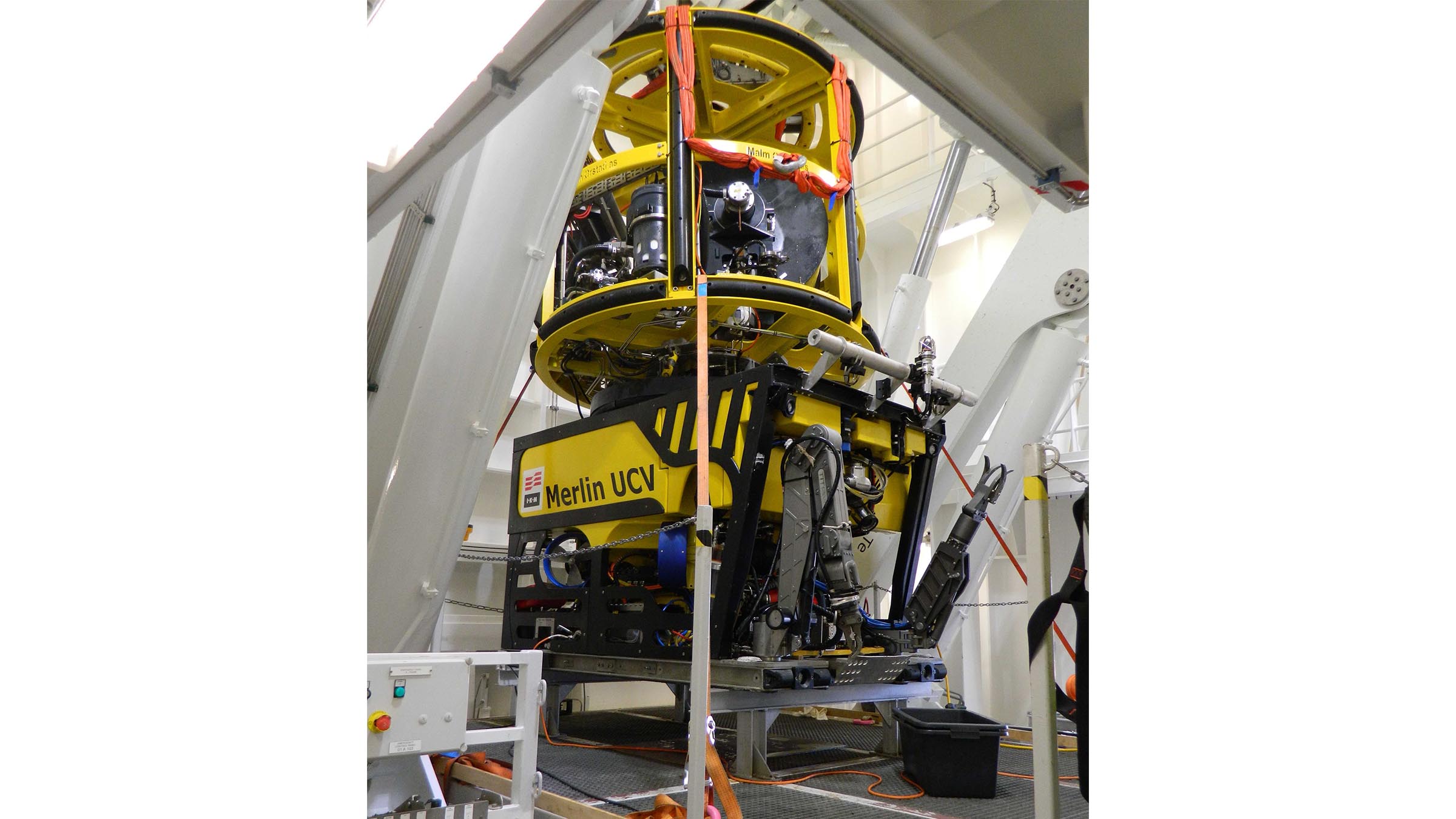

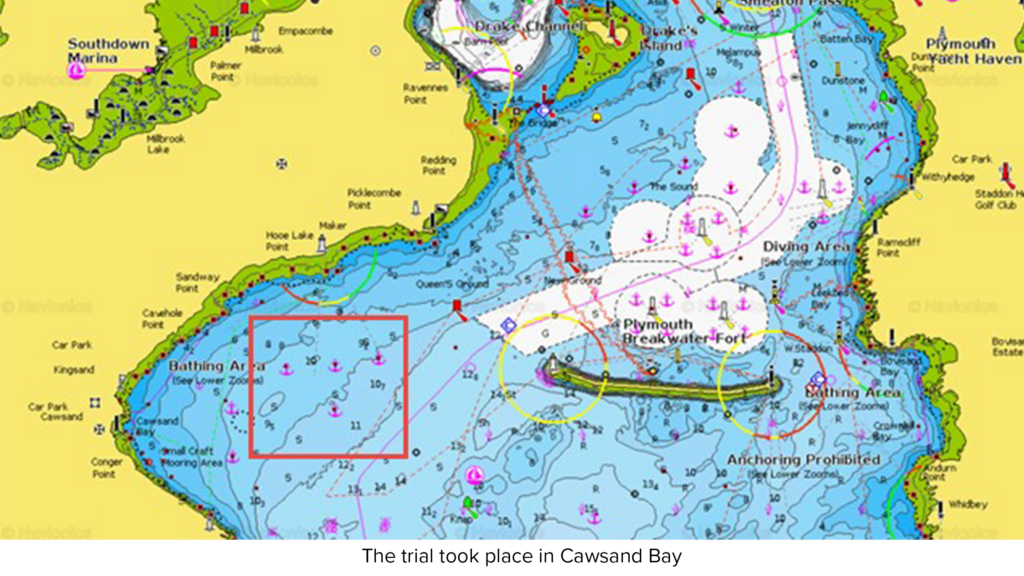

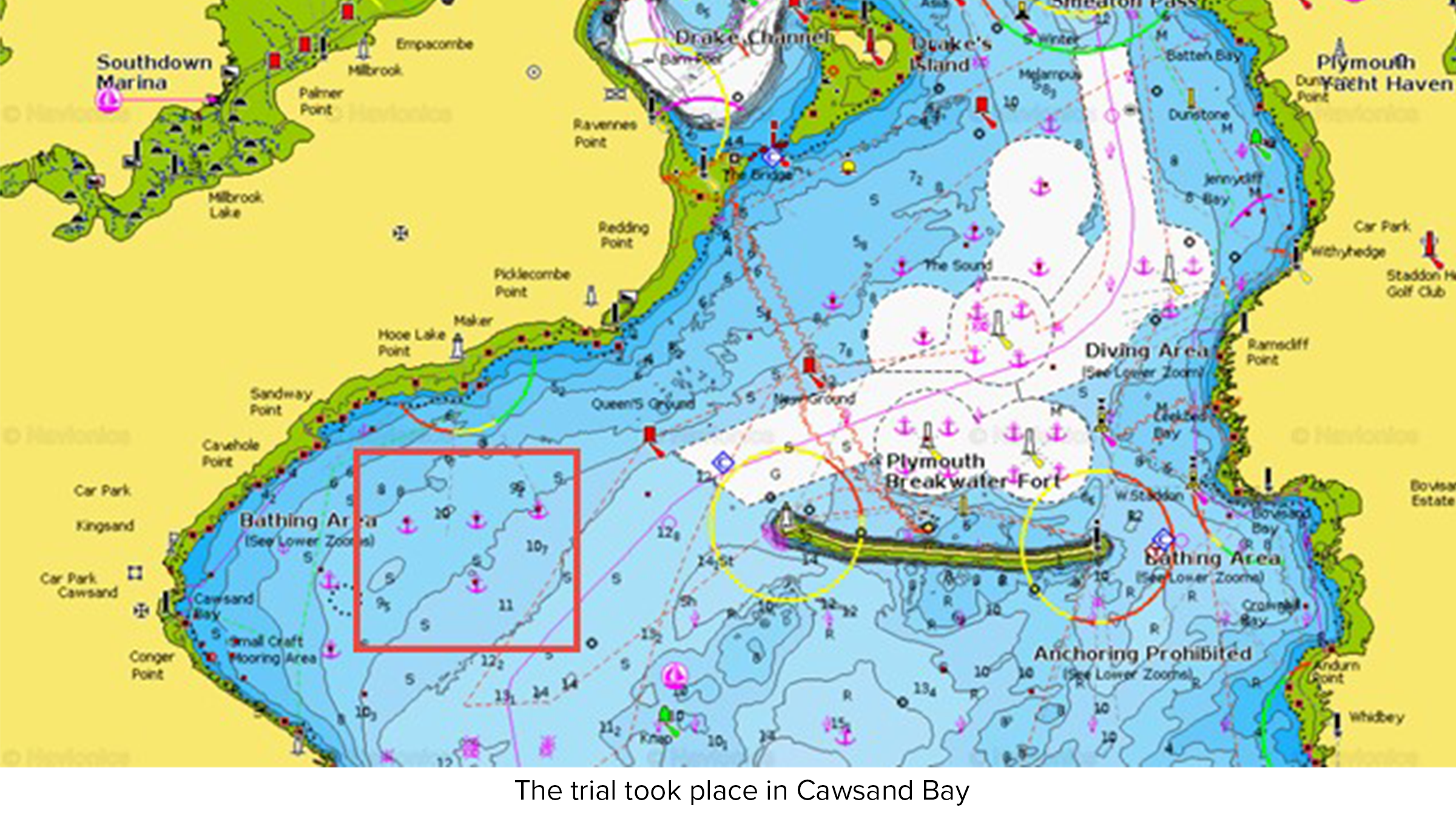

A proof-of-concept trial was conducted in Plymouth Sound in April 2023, with the aim of establishing the range and quality of data transmittable from the seabed via Origin and a USV to the shore.

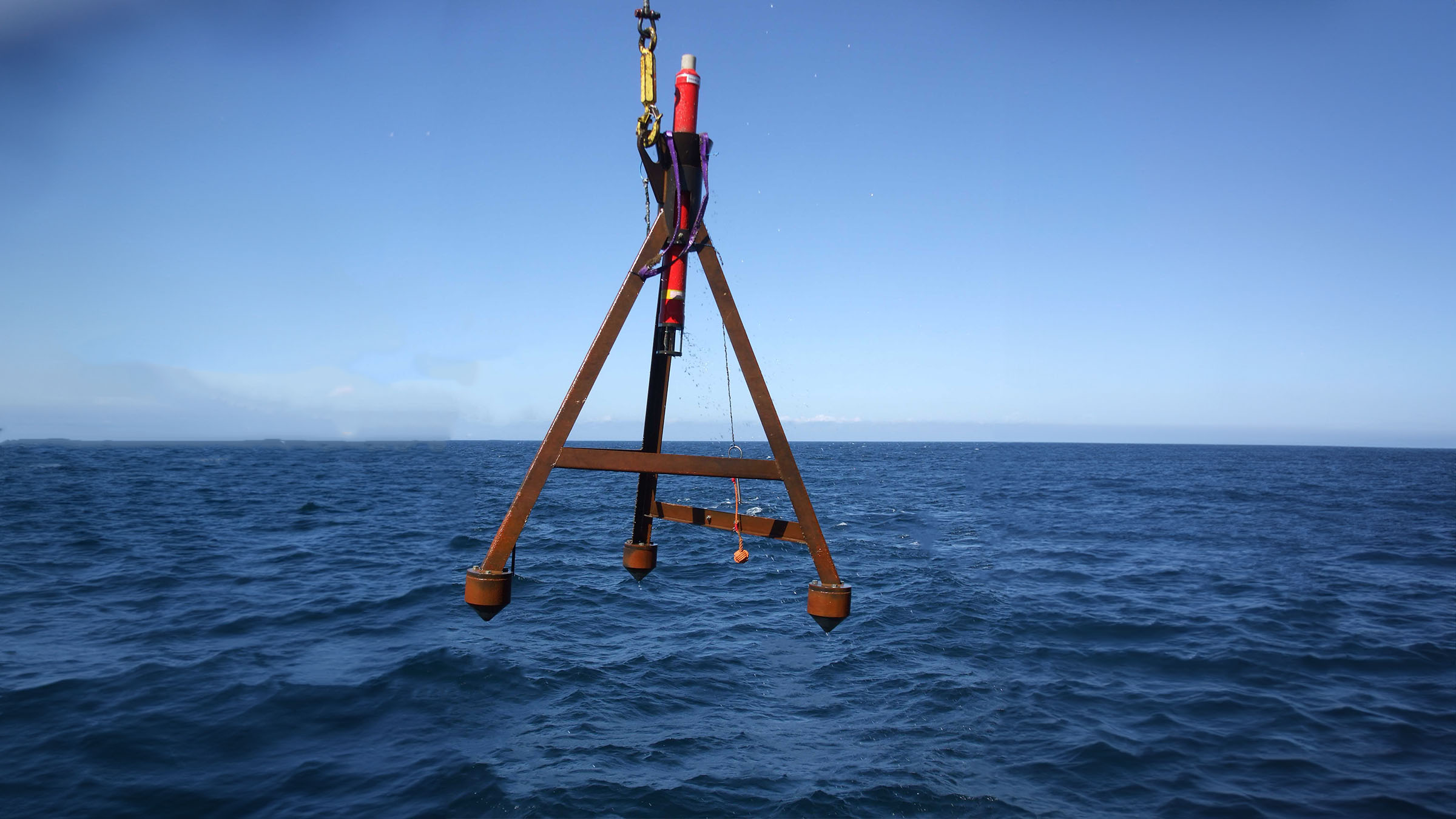

An Origin 600 was mounted on a tripod frame and integrated with a third-party turbidity sensor before being deployed at a depth of approximately 8m in Cawsand Bay. For the purposes of the test, Origin was configured, via the Edge processing app, to average out its readings alongside those from the turbidity sensor for the previous 20 minutes and to send the results acoustically every five minutes. In a real-world scenario, this update rate would usually be configured less frequently.

Our USV ‘Decibel’ was fitted with; an Avtrak6 Nano to receive the data, a deck topside box running the Origin topside software and a control unit payload supplied by the Metocean, Science and Technology team at RPS, to push the data to a Cloud storage via Iridium. For this trial, the team at RPS took LiDAR technology and integrated it into a buoy with power, data storage and satellite communication capabilities. Applying deep expertise of offshore measurement, the design and development process was focussed on creating a reliable design to maximise data accuracy and return, while making the process of information gathering easier and more cost-effective.

Decibel then hovered on the surface above Origin and performed a slow drift off test to establish an understanding of communication coverage/range limits. A lateral excursion of 87 metres was achieved, which equates to a very small elevation angle of almost five degrees – important for shallow water buoys in areas with strong tidal patterns. Once the test was complete, data that had been stored by Origin was compared to the data it had transmitted to the Cloud, via the acoustic modem, Nano and the RPS control unit.

As expected, there was no significant difference between the two data sets other than Origin storing more data than was transmitted to the cloud. This was due to the USV drifting off location to test its range. In a real-life situation, a USV or buoy would maintain a set position and link to the Cloud so more data would be transmitted.

The trial proved proof of concept getting data into the Cloud. Further work is now underway into how we can further integrate Origin with floating LiDAR buoys.

Edge’s future value to offshore wind

As discussed, Edge computing enables users to process data directly on the Origin 600 and send only the critical information over the acoustic modem to the topside. This approach has numerous benefits, including early data insights, more efficient data management at the front end and a sense of relief that the unit is performing as expected (or reducing PDA: post-deployment anxiety!).

Implementing Edge computing via an Origin ADCP can help revolutionise the way in-situ ORE monitoring is conducted in the future. Processing the data at source before transmission reduces data overload by focusing solely on critical information. When combined with AI learning, it will reduce data swamping, lead to quicker but better decision-making and, hopefully, help get turbines in the ground sooner. All while advancing the move towards cleaner, greener, autonomous ORE operations.

Transponders provide reliable releases for Allton offshore Norway

When placing vital equipment such as Nodes on the seabed you need to be sure that you can retrieve them. During the development process, a lack of other products available in the marketplace that met their requirements led Norwegian technology and service company Allton to turn to Sonardyne for a solution.

Starting life as Petromarker in 2005, Allton has been operating offshore Norway for almost 20 years. The company specialises in: marine subsurface electro-magnetic (EM) data acquisition and imaging for hydrocarbon exploration and production, CO2 measurement, monitoring and verification for carbon capture sequestration and marine mineral exploration. It has now expanded its technology and service offering to include multiphysics joint acquisition of both EM and seismic OBN data.

With their innovative multiphysics platform relying on the data they retrieve from both EM and seismic OBN nodes, Allton need to be one hundred percent confident that they can locate and recover their nodes once they’ve been deployed. This can be from depths of up to 3,500 m in often challenging conditions.

When Allton expanded its operational work department and began the redesign of its subsea equipment, a search began for new and reliable solutions as existing transponders and release mechanisms were unsuitable for their specific requirements.

With several decades of subsea transponder and release manufacturing experience, Sonardyne was an obvious choice for a solution.

Our RT 6 family of acoustic release transponders combine the extensive track record of our previous models with the flexibility of a 6G hardware platform, meaning they can be deployed, located and released using any of our Ranger 2 USBL systems or 6G topsides.

An acoustic release transponder is fixed to a subsea asset so it can be found and recovered. An acoustic signal from a surface vessel locates the transponder on the asset. A second acoustic signal then tells the transponder to release the mechanism anchoring the asset to the seabed so that it can be retrieved.

Having gained a full understanding of Allton’s requirements, our engineering team worked closely with them to custom modify an existing RT 6 model to meet their exact needs. Aleksander Kristiansen, Supply Chain and Asset Manager, from Allton explains, “The custom manufacture of our RT 6-4000 was based on an existing model (RT 6-1000) which Sonardyne modified to suit our operational needs. This included extending its range and adding a secondary burn release circuit.

Working with our customers to fully appreciate their needs and the challenges their businesses face enables us to develop solutions for their specific operations. As Trevor Barnes, Sonardyne Sales Manager, explains: “Allton was looking for a robust, reliable acoustic release to give them confidence in retrieving their equipment from a range of depths. Whilst our RT 6-1000 is perfect for depths of up to 1,000 m, Allton operate in depths of up to 3,500 m so our engineers worked closely with them to develop an RT 6-4000 to enable this. A secondary burn-wire release was also added at their request, as a backup in the unlikely event that the first acoustic release fails.”

Aleksander Kristiansen continued “Sonardyne were always willing to assist and put the right technical expertise onto the variety and wide range of tasks to solve our many, often complex at times, challenges. Their creative ideas were well aligned with our expectations and letting us borrow equipment for an extensive time to conduct in-house testing was much appreciated. It gave us further confirmation that we were making the right choice in the RT 6 releases.”

Allton’s nodes are now fitted with RT 6-4000 acoustic releases to ensure that they can be reliably located and retrieved from the seabed at all their operating depths and in any conditions.

They can now provide data across all of their services with confidence that they have consistent, reliable access to their network of nodes.

Our standard RT 6s come in three depth ratings, 1,000 m, 3,000 m and 6,000 m and all use our workhorse Ranger 2 USBL system or deck topside to command and track. Some models can even be controlled using an Android app.

If you have a similar operational challenge, take the worry out of mooring and retrieving your kit and talk to us today.

Operating a small robotic platform in any marine environment is not without its challenges. Reliability and precision with accurate positioning data are key for safe operations and where repeat inspections or surveys are needed.

The size of the platform may present its own limitations, restricting the size and weight of any payload and therefore the extent of its operational capabilities. Environmental or locational factors may also play a part in the reliability of operations. Most navigational and positioning payloads use magnetic compasses to provide heading. This reliance on magnetic heading makes the platform susceptible to interference from ferrous materials in its surroundings. These could be wind turbine or energy platform monopiles, wreckage or unexploded ordnance (UXO) on the seabed, the presence of vessels / submerged infrastructure in harbours and coastal locations or even just naturally occurring ferrous minerals in the seabed.

These factors introduce heading errors that compromise the supervised autonomous functions of the platform, particularly when following line headings between reciprocal bearings. Even minor heading inaccuracies can cause cumulative deviations over extended missions, leading to imprecise data and potentially requiring time-consuming survey line re-runs.

Any inaccuracies during survey when locating UXOs are particularly unwelcome, by their nature most UXOs are located based on magnetic signature. So, any poor navigation during the wide area or detailed UXO survey can be misleading and potentially dangerous. With repeat inspections of monopiles, for example, ensuring the survey platform returns to the exact same spot on each visit is important to ensure no anomalies or potential problems are missed.

Heading accuracy

0.15°

Regardless of the environment

Depth rating

0

m

Weight in water

0.6kg

“Historically, smaller electric vehicles have been limited in the amount of work they are capable of due to size, power and operational limits presented by weather conditions and surroundings.

Recent iterations of handheld ROVs such as the VideoRay Defender have looked to change what electric ROVs are capable of, while maintaining a platform that is easy to mobilise, operate and maintain. That said, the ROV is only as powerful as the tooling that it holds, so it still requires support from companies such as Sonardyne, to reduce the form factor and weight of their tools and sensors, to enable their integration and deployment offshore.

Atlantas Marine have already been utilising the SPRINT Nav Mini to great success on our Ocean Modules V8 M500 platform, but the latest SPRINT-Nav U will allow us to go further and integrate it onto our VideoRay Defender ROVs, and provide another service that we can offer our customers – a hand-launched ROV, that can be mobilised in as little as half an hour, transported to site in the back of an car” Mark Salter, Senior Project Manager, Atlantas Marine.

“Like the other hybrid navigators in the SPRINT-Nav family, SPRINT-Nav U’s true north seeking gyrocompass means that it delivers reliable subsea navigation even when in close contact with the types of environmental factors outlined above. With its ultra-compact form factor (135mm X 114mm) and a weight in water of just 0.6kg, SPRINT-Nav U gives unrivalled navigation capability to small marine robotic system allowing users to maintain a heading accuracy of 0.15° regardless of environmental factors.

“SPRINT-Nav U has been designed with our customers in mind. We’ve been speaking to them for a number of years about their aspirations for operations with small platforms. With the help of valued customers like Atlantas Marine, our trials have demonstrated a variety of use cases for this new, compact navigator and we’re excited to work on many more innovative uses in future.” Aidan Thorn, Business Development Manager – Marine Robotics, Sonardyne.

Small, light, precise

SPRINT-Nav U is simple to integrate into any marine vehicle along with other payload sensors and uses same field-proven web user interface found on the SPRINT-Nav Mini. Pre-calibration in the factory also means that SPRINT-Nav U is incredibly quick to set up and deploy on site with an alignment time of as little as five minutes, compared to the standard 15-20 minutes of other gyrocompassing inertial navigation systems, making it the world’s fastest aligning hybrid navigator.

“SPRINT-Nav U can turn any marine robot into a survey grade platform. For UXO and asset inspection it drastically improves deliverable data quality. As part of the proven Sonardyne SPRINT-Nav family, customers can be assured of reliable, accurate navigation and positioning every time, no matter the operating environment.” John Houlder, Senior Product Manager, Sonardyne.

“Of particular significance to us, is the work we undertake on offshore wind turbines. With a high AC voltage running through the subsea cabling, and the strong magnetic signatures associated with that, plus the ferrous nature of the turbines themselves, the SPRINT-Nav U allows us to offer our customers a level of accuracy and precision that was previously not possible. It allows us to state with much higher confidence the location of any faults and anomalies, and allows us to repeat inspections, year on year, as we document the changing condition of those faults. With the positioning and control managed through Greensea, we can set up autonomous routes and sea patterns with more accuracy and precision than even before, especially in the environments we most commonly find ourselves.”

Mark Salter, Senior Project Manager, Atlantas Marine.

“Providing improved accuracy when operating in ports and areas where large metallic objects are buried on or beneath the seabed, improves not only the reciprocal bearings of the lanes the ROV is flying, but feeds a more accurate heading into the navigation solution which is streamed to the surveyor.

Beyond seabed surveys, the ability to maintain a stable heading while piloting a compact inspection-class ROV through culverts with rebar or complex subterranean tunnels is a key advantage. It reduces the need for frequent heading corrections and ensures precise navigation when traversing long distances. This ultimately enhances the quality of deliverables for our clients, providing us with a competitive edge when deploying our equipment.”

Richard Stanley, Project Leader, Atlantas Marine