Using a hammer to crack a nut? Try using a USV instead

USVs are no longer new. They’ve been used in defence for some time now, for a range of tasks from surveillance to mine counter measures. USVs are being used to survey coastal and offshore waters in hydrographic surveys, for ocean science and in oil and gas

The challenge

Crewed vessels used in offshore construction projects are costly and can even hinder progress. But it doesn’t have to be that way. Other sectors that operate in the marine space are now finding new, smaller, smarter, cleaner tools. They’ve been using uncrewed surface vessels (USVs), so the big, crewed vessels can stick to the jobs they’re good at.

So why are we not using them heavily in offshore construction?

One reason may be because offshore construction was in fact an early adopter. But, at the time, there were only a handful of commercial USV operators whose vehicles were just too big for what was needed, making them unwieldy to deploy from an offshore vessel, defeating the point of the exercise.

Another may be the worry of the complexity involved in offshore construction. Creating complex structures on shore is one thing. Creating them under metres of salt water is entirely another.

Then there is the issue of communication and control over the construction process. Making sure each step is taken exactly as planned is fundamental to the overall success of a construction project.

The solution

USV technology has come a long way since their inception. They’ve been used in defence for some time now, for a range of tasks from surveillance to mine countermeasures. USVs are being used to survey coastal and offshore waters in hydrographic surveys, for ocean science and in oil and gas. They’re being used to go out and gather data, either as a platform for oceanographic instruments or by carrying acoustic communications systems to harvest data from sensors deployed at the seabed. You could think of them being like a remote-controlled Dunker.

USVs are now part of the toolbox across a number of sectors and the levels of sophistication and capability are increasing. Worries about lack of control, the complexity of operations or large clunky kit that isn’t up to the delicate tasks required in offshore construction are today unfounded.

In offshore renewables and oil and gas USVs are being used as part of site and seismic surveys, and then through field life, for inspection operations. They’re also being used for maintenance and repair, by acting as deployment platforms for autonomous underwater vehicles (AUVs), remotely operated vehicles (ROVs) and even aerial drones (UAVs).

The results

Today there’s a wide choice of USVs to choose from. From one-man portable USVs to full sized vessels, and on to fully electric coastal systems and hybrid long-range ocean-going vehicles that can operate for weeks on end. The range of commercial models has also grown. You can buy them outright or purchase a data service where you just order the end result – be it data or an inspection campaign.

USVs can now play a central role in construction operations. They can streamline operations and reduce risk for manned offshore construction teams. When deployed they reduce reliance on heavier, costlier tools and free-up crewed assets to be used on elements of a project where they’ll bring more value.

Deploy, retrieve, repeat – made easy with RT 6 acoustic release

Deploying sensors in a strong-current tidal estuary is a challenge. Try retrieving them and then redeploying them back in exactly the same position, multiple times. It’s a task vastly simplified with our RT 6-1000 release transponder, used alongside any of our Ranger 2 family of Ultra-Short BaseLine (USBL) systems.

The challenge

Deploying, locating and retrieving seabed sensors can be a challenge. Choosing reliable sensors that will work for the whole duration of the deployment and provide robust reliable results is just the start. Accurate seabed positioning data that are delivered in real-time to enable dependable acoustic release of the sensors is also required.

An additional layer of complexity is introduced for these kinds of operations when the site in question has a significant tidal range and current regime.

This is just what independent physical oceanography consultancy DynamOcean has been doing in the Rance estuary in Brittany, France. The Rance estuary – where the River Rance enters the English Channel – has one of the largest tidal ranges in France. It averages around 8m between low and high tide. During spring tides this figure can jump to as high as 13.5m!

DynamOcean has been studying sediment transport through the estuary with the aim of measuring current, waves and turbidity in the Rance estuary. To do this, they’ve been using an acoustic Doppler current profiler (ADCP). The measurements are being taken over six months, with recovery and re-deployment of the ADCP – in exactly the same position – every two months. This requires both a reliable acoustic release and accurate seabed positioning in real-time.

The solution

For this project, DynamOcean chose our RT 6-1000 acoustic release transponder. Their choice was guided by several years’ experience in using our Lightweight Release Transponder (LRT) and deciding to upgrade to our newer RT 6-1000.

The RT 6-1000 is our entry-level release transponder with features that are far from entry-level. The 1,000 m depth rating, 15-month battery life, optional rope canister and – crucially – the reliable release mechanism made this an ideal choice for the deployment, retrieval and redeployment work DynamoOcean needed it for.

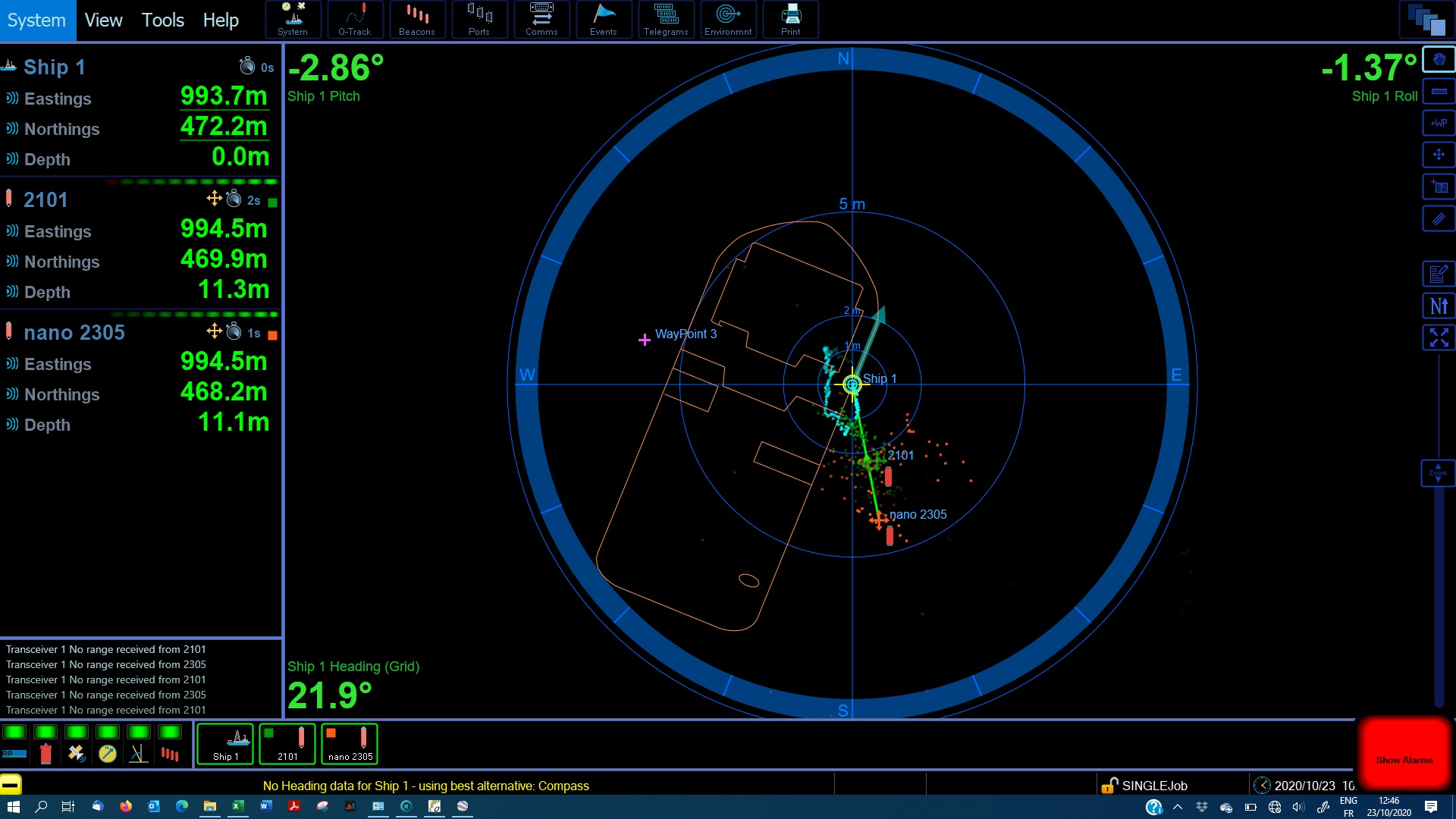

Alongside the RT 6-1000, DynamOcean chose our Micro-Ranger 2, the smallest USBL system we have available at Sonardyne.

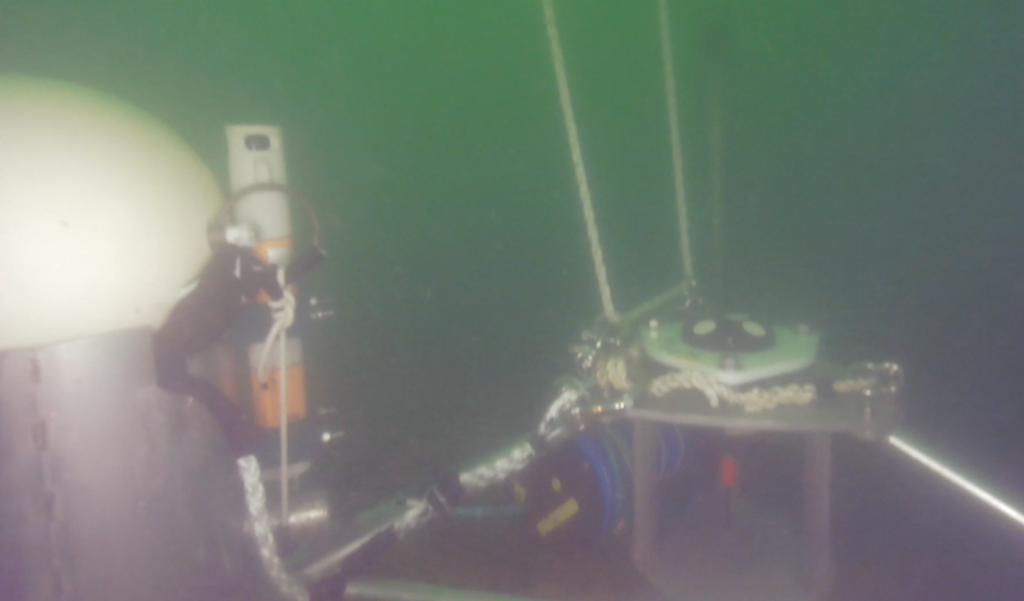

It’s easy to set up and use – even from a RIB or uncrewed surface vessel (USV) – and enables tracking of up to 10 targets out to 995 m range. For this project, it means DynamOcean can instantaneously position its seabed ACDP platform and inspect it using a mini-ROV, which can also be positioned via a Nano beacon using the same Micro-Ranger 2 topside.

Because the RT 6-1000s, Nano and Ranger USBL systems work with the same 6G platform, they can be used interchangeably and seamlessly. The time needed to coordinate each part is minimal and integration with the topside platforms is simple.

DynamOcean’s managing director Eloi Droniou explained the three key benefits they enjoyed when speaking with us about the setup for the Rance estuary project:

“The RT6-1000 integrated within a pop-up buoy on the seabed platform has multiple purposes,” he says, “one, release the pop-up buoy for the recovery of the seabed platform without the need for divers at the end of the measurements; two, measure inclination to make sure the platform is more or less level; and three, position accurately the seabed platform using various Sonardyne 6G topside options.

“With the release of Micro-Ranger 2 and Mini-Ranger 2, DynamOcean was thrilled to be able to not only instantaneously position the seabed platform but also to inspect it using a mini ROV, [which was] positioned using the lightweight and compact Nano transponder.”

The results

“This allows us to make sure that it has landed properly, without needing any divers,” adds Droniou. “If the landing location is not satisfactory, the seabed platform can be raised from the seabed and moved to another nearby location. The seabed platform can also be inspected with the mini ROV just before releasing the pop-up buoy with the RT 6-1000 to check that everything is in order and verify the instrument’s height above seabed.

“Having the positions of the vessel, the seabed platform and the mini ROV, simultaneously and on the same survey window (Ranger 2 software), is essential for these operations.”

DynamOcean were able to simplify their operation, thus cutting costs and the time needed to position, deploy, retrieve and redeploy sensors for the estuary study. On top of this, because the need for divers was removed the risk associated with the study has also been reduced.

DVL aiding – in the harshest environments

In pipeline inspection operations, for example, it’s preferable to get the vehicle as close to the seabed – and the pipeline it’s inspecting – as possible. But, this can cause the DVL’s bottom lock to be compromised, due to being too close to the seabed.

The challenge

For a number of operations, getting survey and positioning sensors as close to the seafloor as possible is important. However, this can lead to special requirements for sensor and vehicle design and an increase in operational complexity. Mounting the Doppler Velocity Log (DVL) with an unobstructed downward view, to achieve bottom lock, can become particularly difficult.

When operating ploughs or trenchers, most mounting options – eg. pointing the DVL directly towards the seabed, as is commonly done – compromises the DVL’s accuracy, due to the highly turbid water created by the vehicle it’s mounted on and the DVL beams being reflected or blocked by the trencher or plough itself.

One option, in these applications, is to separate the DVL from the inertial navigation system (INS). This allows more flexibility in terms of where the DVL is mounted. However, this can also adversely impact navigational accuracy, as it introduces lever arm and mounting angle errors between the INS and the DVL. Furthermore, performing DVL to INS calibrations are often impossible or very impractical on vehicles such as ploughs and trenchers, because vehicle manoeuvrability is not suitable for calibration purposes.

A solution for DVL mounting that improves flexibility on integration without compromising performance is required.

The solution

When mounting a DVL, one of the limitations is that optimal performance often requires vertical mounting. Our SPRINT-Nav – a compact INS and DVL in one – removes this limitation as it can be mounted at an angle. This avoids turbidity and the vehicle’s own infrastructure, which would otherwise interrupt its DVL beams.

The SPRINT-Nav can do this because the DVL it contains is tightly integrated at beam level. Each individual DVL beam is fed directly into the INS solution, instead of feeding in a 3D velocity solution that the DVL resolves by itself. This low-level integration means that SPRINT-Nav does not rely on the DVL alone for resolving a 3D velocity solution – it is handled more optimally by the INS. The SPRINT-Nav is then constrained and, critically, can be mounted at an angle, without compromising accuracy.

The idea of mounting the SPRINT-Nav at an angle was initially raised during a meeting with offshore survey solution provider UTEC. The concept instantly sparked great interest, as it had not previously been possible with existing INS solutions.

The next step was to test and evaluate how the alternative SPRINT-Nav mounting arrangement would perform for this specific application. The operation chosen for the evaluation was a cable lay project in the East Anglia ONE offshore wind farm, in the UK’s southern North Sea. There, UTEC was working from DeepOcean’s Maersk Connector cable lay vessel, providing positioning of DeepOcean’s plough during simultaneous lay and trench of a cable. UTEC’s objective was to get an accurate INS/DVL based position for the plough in order to replace the USBL positioning which had been degraded by acoustic noise from the vessel thrusters.

The project included both shallow and deeper water operations, with some very challenging conditions – highly turbid water, changing altitudes from the varying plough depth and sand waves and a very high level of vibration. Additional considerations included varying speeds as the plough made its way along the seabed and intermittent, noisy USBL updates from long layback tracking and vessel thrust.

All-in-all, it was a very tough application, in a very demanding environment. Both the inertial solution and the acoustics were thoroughly put through their paces. All the same, we were confident that SPRINT-Nav would perform well, despite the challenges it faced.

The ring laser gyro (RLG) technology used within SPRINT-Nav is almost immune to vibration; this is not the case for other competing gyro technologies. The tight beam-level DVL aiding increases robustness, so even if the DVL loses bottom track periodically or loses individual beams high levels of accuracy and reliability are maintained. What’s more, the pre-calibrated SPRINT-Nav does not rely on any additional calibrations or fine-tuning to ensure performance and the robustness of the SPRINT-Nav solution makes it less dependent on regular USBL updates.

This mounting arrangement had two benefits. Firstly, the SPRINT-Nav would always have four DVL beam returns as opposed to mounting it vertically, which would cause at least one of the beams to bounce off the plough’s infrastructure. Secondly, three out of four DVL beams would be directed away from the most turbid water surrounding the plough. This improves the signal-to-noise ratio and provides a more robust INS solution.

A bespoke mount was manufactured for this project. This enabled us to adjust pitch and yaw angles when needed during testing. Furthermore, post-processing in our Janus software was proposed to deliver the most accurate as-laid cable data.

The cable lay project was divided in three parts: integration and mobilisation; shallow water shake-down; and ploughing. A Sonardyne engineer was present for the initial shallow water shake-down and after a review of the integration, the system was deployed.

Throughout, SPRINT software was used to monitor the raw beam velocity data from the SPRINT-Nav’s integrated DVL. It became instantly obvious that all beams were achieving a good lock, even with the 30° pitch angle. It was also seen that the system continued to observe good data throughout the entire operation.

0

degree

angle of operation

SPRINT-Nav

0

m

depth rating

The results

Throughout both the shallow water and deeper water cable lay operations, the SPRINT-Nav performed well and no performance degradation from the 30° pitch angle mounting was experienced. On-board team members also found the topside software (SPRINT) intuitive and very useful for troubleshooting and tweaking the system.

As the environment was very new to Sonardyne (low speed, jerking motion, high turbidity), we also collected a lot of very useful data. This included DVL and INS data, which has helped us to understand how we can further improve the set up for these and similarly challenging applications.

We thank UTEC and DeepOcean for supporting this trial and look forward to providing this solution on future projects.

Shallow water site investigation for offshore wind

From the topside to the underwater instruments, our goal is to make offshore operations easier and less time-consuming, but also highly accurate. As PDE Offshore discovered, with Mini-Ranger 2, our 6G hardware and our Wideband 2 digital acoustic technology onboard, safe and efficient shallow-water site investigation operations, from tracking towfish to positioning seabed geotechnical equipment, are assured.

The challenge

In a short period of time, Taiwan has quickly become a leader in the global build-out of offshore wind. Starting from scratch in 2018, the country has been quick to ramp up its offshore wind capability. Taiwanese company PDE Offshore, based in New Taipei City, was quick to get involved in this new industry and came to us for a USBL system to underpin its offshore wind geotechnical site investigation service offering.

Specifically, it was looking for a system to support geotechnical site and soil investigation works for a new offshore wind farm in the shallow water Taiwan Strait. This involves deploying geotechnical drilling equipment on the seabed at each planned turbine site in just 20 – 60 m water depth. The frame holding the equipment has to be positioned accurately to ensure it’s aligned with the drill string deployed from PDE Offshore’s geotechnical survey vessel.

The solution

PDE Offshore chose a combination of our Mini-Ranger 2 USBL system and our Wideband Sub-Mini 6+ (WSM 6+) transponder/responders to track and position their drilling frame on the seabed. Mini-Ranger 2 is built around the same market-leading 6G hardware and Wideband 2 digital acoustic technology you’ll find in our entire family of USBL systems – even the software is the same.

Critically, it’s designed to easily handle just the kind of shallow waters PDE Offshore had to work in on the project in the Taiwan Strait. At the heart of Mini-Ranger 2 is our HPT 3000, a highly capable surface-deployed USBL transceiver that’s optimised for high performance in shallow water, as well as high elevation and long lay back operating scenarios and data telemetry.

It was a simple choice for PDE Offshore, not least as their onboard surveyor was already familiar with Mini-Ranger 2. What’s more, it’s also a great option for smaller vessels and even unmanned surface vessels (USVs).

A wide range of Sonardyne 6G transponders can be used with Mini-Ranger 2, allowing you to select the most appropriate took for each task. For its operations in the Taiwan Strait, PDE Offshore chose our Wideband Sub-Mini 6+ (WSM 6+) transponder/responders. Designed for positioning ROVs, towfish and other mobile targets in water depths up to 4,000 m, WSM 6+ incorporates our Wideband signal technology, so it offers superior ranging accuracy and fast USBL position updates as well as full two-way Wideband support – interrogation and reply signals.

Targeting

0

GW

by 2025

0

m/s

average wind speed

Average water depth

0

m

for each turbine

The results

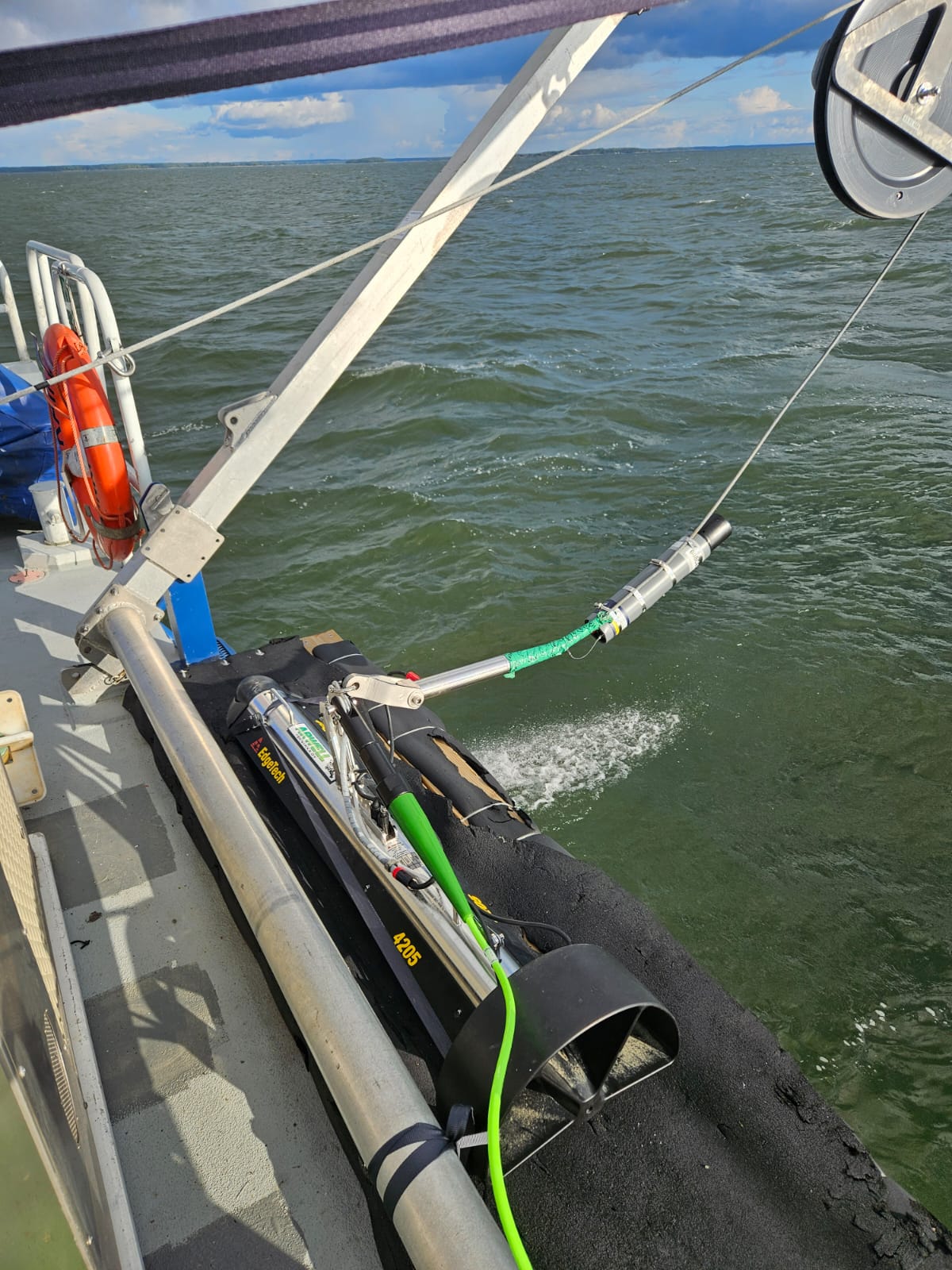

PDE Offshore spent summer 2020 performing site investigation works from the MV Geo Energy in the Taiwan Strait. Our WSM 6+s were mounted on the seabed frame and tracked using the Mini-Ranger 2’s HPT 3000, which was deployed on an over-the-side deployment pole from the MV Geo Energy.

Huang Hsin-chih, president of PDE Offshore, says, “Where we work in the Taiwan Strait, water depth is from 20 to 60 meters; in the future, there might be a chance to work in offshore wind farm with water depth from 50 to 200 meters, so whilst we do need a very precise USBL, we don’t need one that’s full ocean depth capable. Through renting, we became familiar with Mini-Ranger 2 and the benefits it brought to our busy geotechnical operations. So it was a simple choice to decide to go ahead and purchase one of our own and it has proven fully capable for our needs on this and future offshore wind projects.”

Facing the challenge of speeding up consent in offshore renewable energy

The drive for cleaner, greener energy set against financial constraints in a challenging world market could mean testing times ahead for offshore renewable energy (ORE).

In order to meet pressing timescales, cost saving criteria and governmental targets for energy production, the industry needs shorter consenting periods for offshore wind projects but also better characterisation data. Better data would suggest the need for a longer, more costly, consenting period. So how can this challenge be met?

At Sonardyne, we believe our Origin® acoustic Doppler current profilers (ADCPs) may offer at least part of the solution. ADCPs use acoustics to measure the water column to determine currents and many can also measure wave motion and turbulence. They can provide metocean data for decision making on where to place floating turbines to ensure moorings are not stressed, determining where scour may occur that will damage cables or structures, array cable selection, route planning and cable’s depth of burial predictions etc.

Obtaining high quality, accurate, current and wave data has always been a challenge in the marine environment. Which is far from ideal when there’s a need for more timely, precise data. Meanwhile, traditional ADCP technology does not have resolution high enough to distinguish fine-scale turbulence. The correct measurement of turbulence is a key factor in ensuring that any planning at the consenting stage is based on accurate data.

With accurate data at the consenting stage, developers can reduce options and decide on the exact foundation solution, maximum turbine size etc. They can then plan with certainty and model simple environmental impact assessments for presentation to the consenting authorities.

Enter Origin…

Our Origin 600 and 65 ADCPs signify a sea change in ocean floor ADCP technology and are the most advanced ADCP’s presently on the market.

Alongside industry standard PD0, new and exclusive A-gram and B-gram proprietary data formats offer up to ten times greater spatial resolution and provide superior quality data for more informed decision making.

The inbuilt acoustic modem provides the ability to; check operating status, test data quality and change schedules mid-mission. It also provides remote access to the customisable Edge data processing applications on Origin. This means that while the device is deployed, it can be programmed to output concise, relevant information, rather than bulky raw data that would normally be processed once the device is recovered from the water. All without the cost and risk associated with interfacing an external modem or running a cabled ADCP operation.

Realising the potential

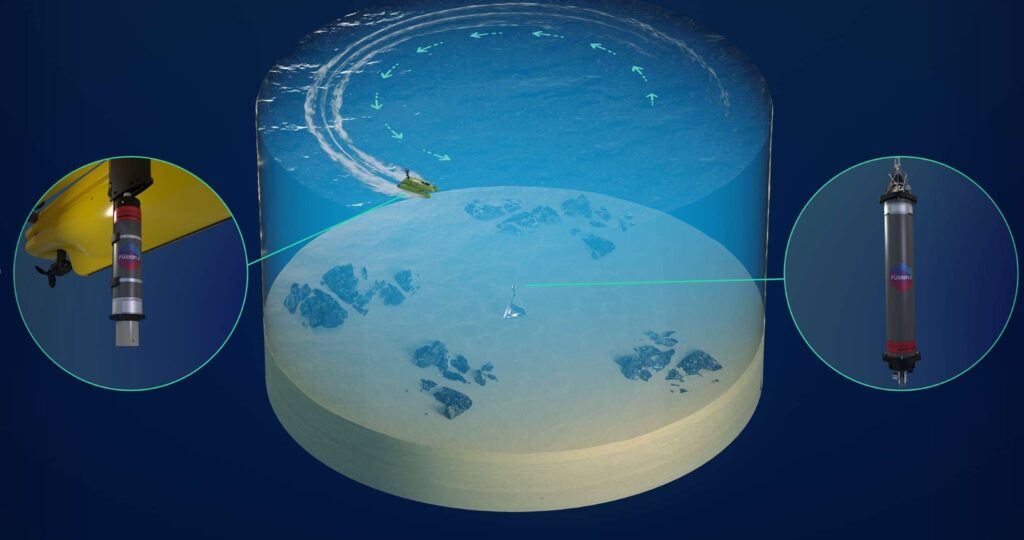

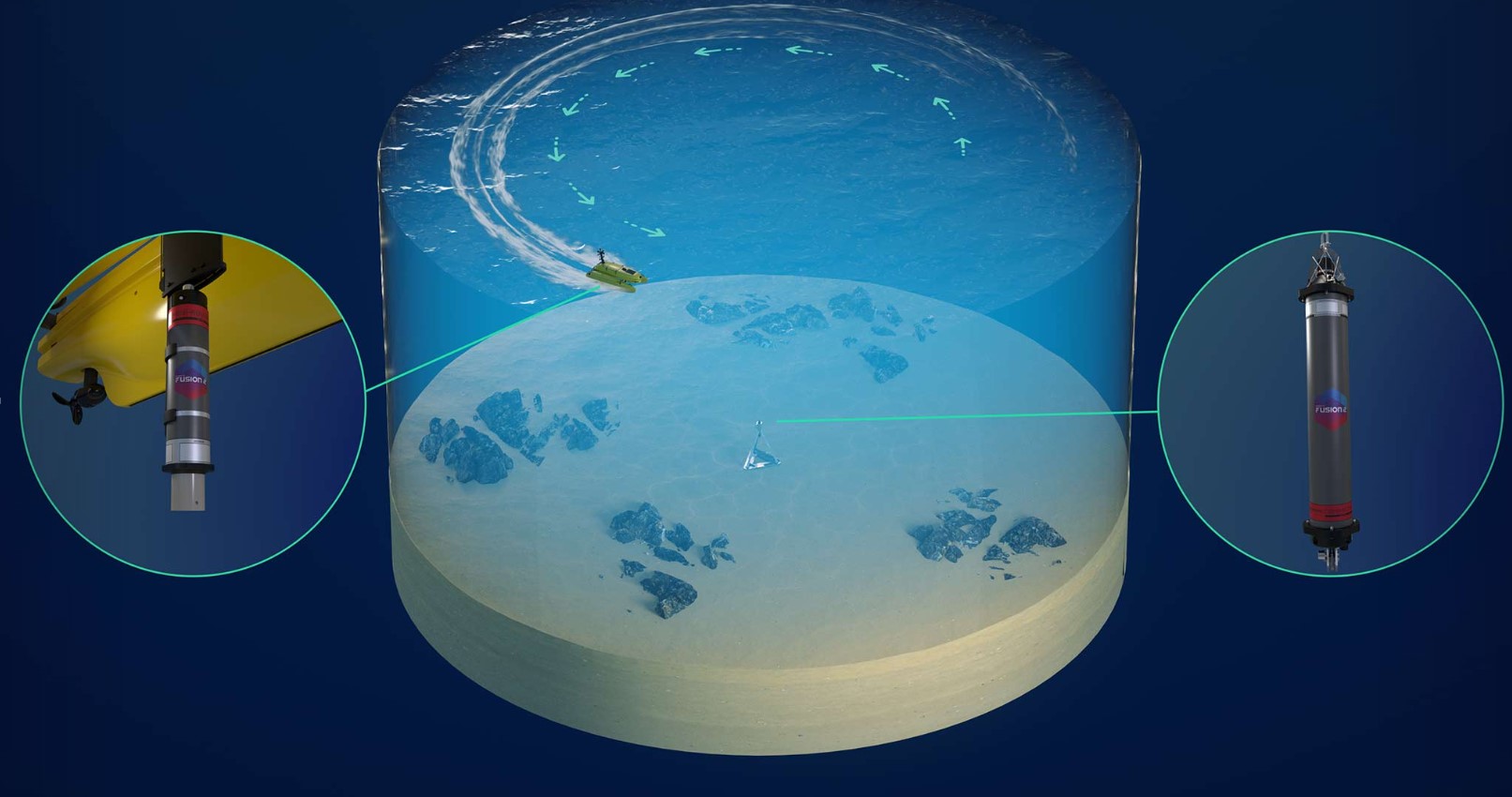

Taking this a step further and combining Origin’s data and communication capabilities with autonomous data collection via an uncrewed surface vehicle (USV) or surface buoy potentially offers many advantages.

Operators can make informed decisions faster as more frequent, concise data samples can be collected throughout the deployment, rather than waiting for the ADCP’s retrieval. Data can be collected at intervals via a USV passing overhead or transmitted to Cloud storage via a LiDAR buoy.

Reduction of carbon emissions during missions can also be achieved. USV data harvesting and an ADCP battery life of over three months are just two in which the need for a carbon-heavy crewed vessel would be reduced. The associated costs and HSE exposure hours would be reduced too.

Origin’s ability to provide high fidelity data, often in near real-time – depending on the harvesting method – offers the potential to meet the data requirements within a shorter timeframe.

Concept testing

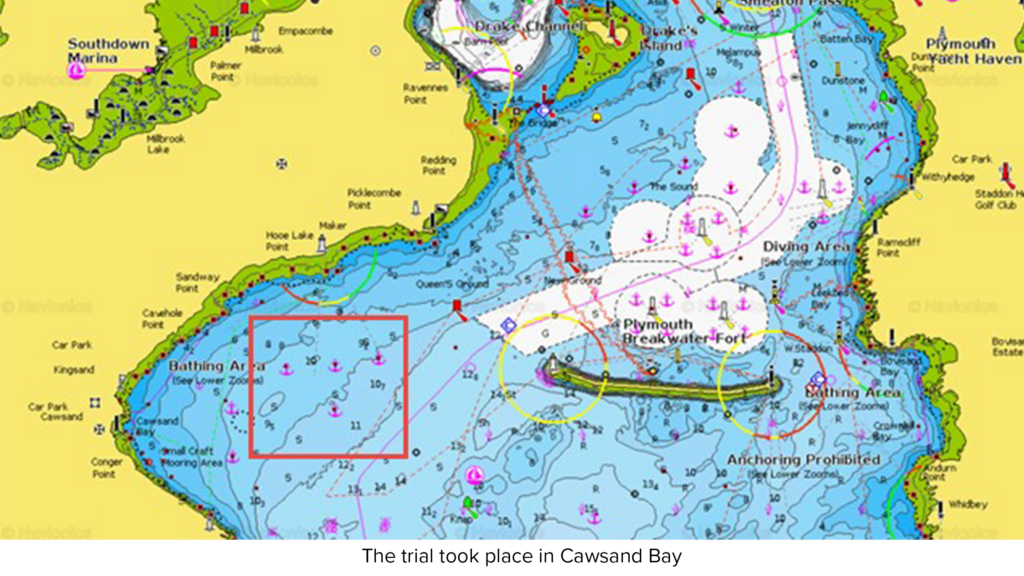

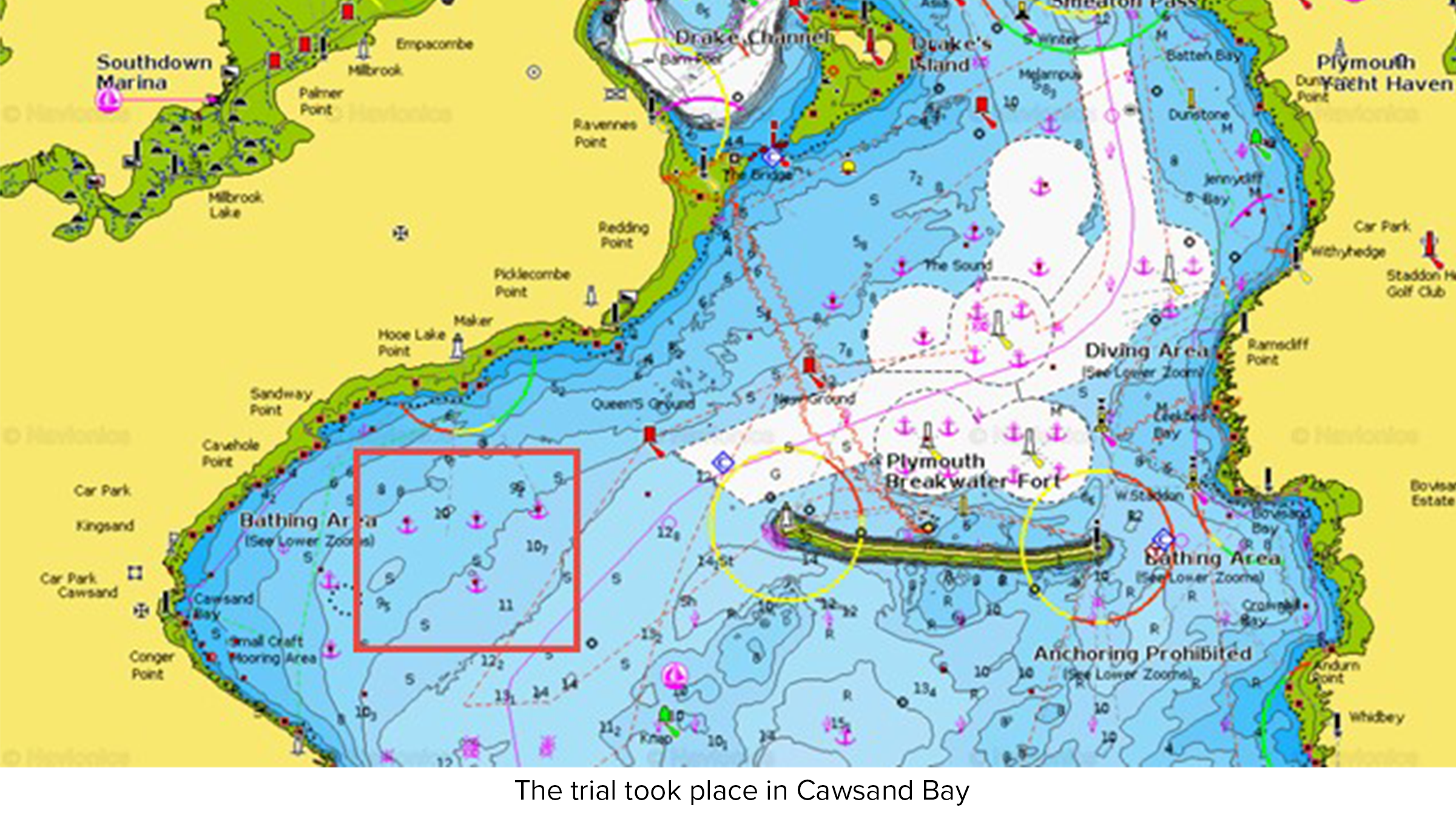

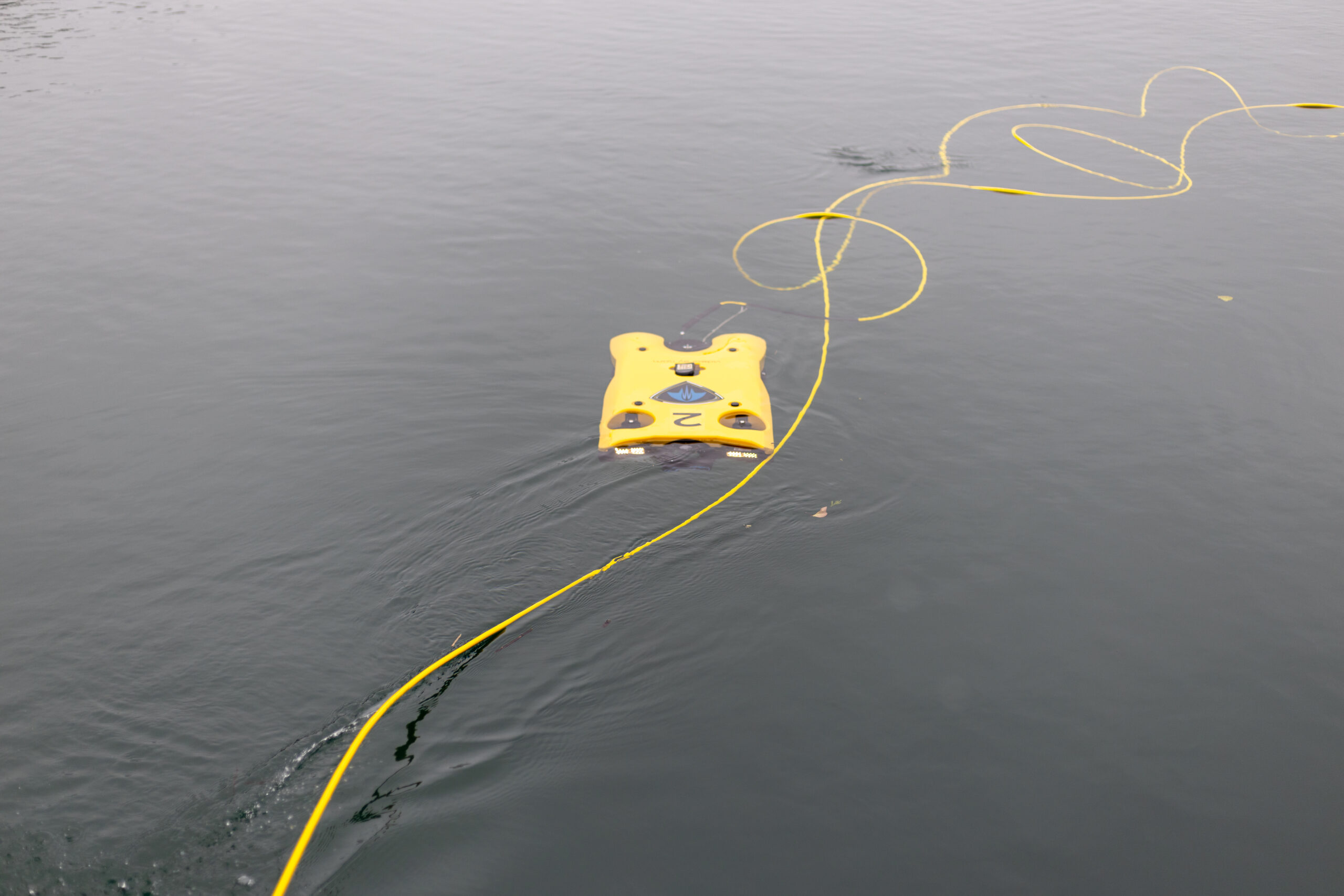

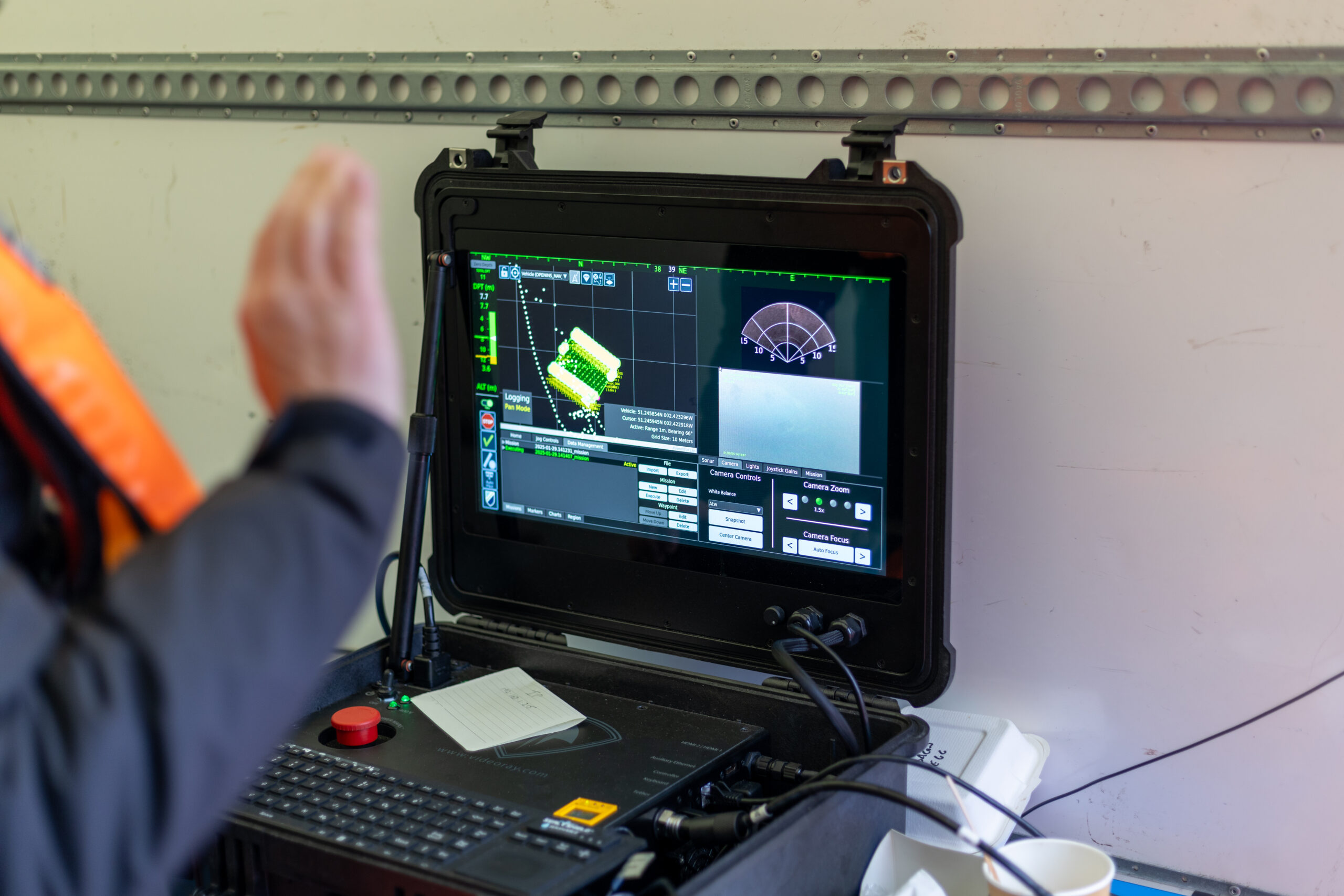

A proof-of-concept trial was conducted in Plymouth Sound in April 2023, with the aim of establishing the range and quality of data transmittable from the seabed via Origin and a USV to the shore.

An Origin 600 was mounted on a tripod frame and integrated with a third-party turbidity sensor before being deployed at a depth of approximately 8m in Cawsand Bay. For the purposes of the test, Origin was configured, via the Edge processing app, to average out its readings alongside those from the turbidity sensor for the previous 20 minutes and to send the results acoustically every five minutes. In a real-world scenario, this update rate would usually be configured less frequently.

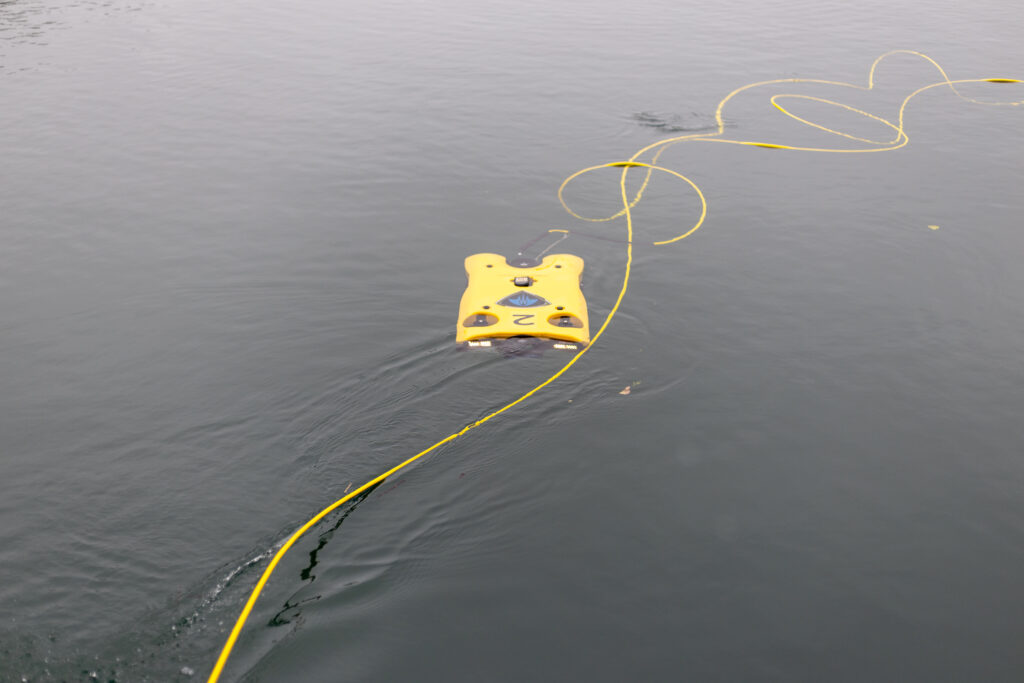

Our USV ‘Decibel’ was fitted with; an Avtrak6 Nano to receive the data, a deck topside box running the Origin topside software and a control unit payload supplied by the Metocean, Science and Technology team at RPS, to push the data to a Cloud storage via Iridium. For this trial, the team at RPS took LiDAR technology and integrated it into a buoy with power, data storage and satellite communication capabilities. Applying deep expertise of offshore measurement, the design and development process was focussed on creating a reliable design to maximise data accuracy and return, while making the process of information gathering easier and more cost-effective.

Decibel then hovered on the surface above Origin and performed a slow drift off test to establish an understanding of communication coverage/range limits. A lateral excursion of 87 metres was achieved, which equates to a very small elevation angle of almost five degrees – important for shallow water buoys in areas with strong tidal patterns. Once the test was complete, data that had been stored by Origin was compared to the data it had transmitted to the Cloud, via the acoustic modem, Nano and the RPS control unit.

As expected, there was no significant difference between the two data sets other than Origin storing more data than was transmitted to the cloud. This was due to the USV drifting off location to test its range. In a real-life situation, a USV or buoy would maintain a set position and link to the Cloud so more data would be transmitted.

The trial proved proof of concept getting data into the Cloud. Further work is now underway into how we can further integrate Origin with floating LiDAR buoys.

Edge’s future value to offshore wind

As discussed, Edge computing enables users to process data directly on the Origin 600 and send only the critical information over the acoustic modem to the topside. This approach has numerous benefits, including early data insights, more efficient data management at the front end and a sense of relief that the unit is performing as expected (or reducing PDA: post-deployment anxiety!).

Implementing Edge computing via an Origin ADCP can help revolutionise the way in-situ ORE monitoring is conducted in the future. Processing the data at source before transmission reduces data overload by focusing solely on critical information. When combined with AI learning, it will reduce data swamping, lead to quicker but better decision-making and, hopefully, help get turbines in the ground sooner. All while advancing the move towards cleaner, greener, autonomous ORE operations.

Delivering subsea synergy in ORE inspections

There are numerous challenges associated with offshore wind visual inspections, including currents, turbidity, time and cost. Sonardyne, EIVA and Voyis, all part of the Covelya Group, are working together to bring a complete imaging, navigation and autonomy solution to overcome these obstacles and enhance the inspection data product.

With almost a century of combined subsea expertise between them, the companies are ideally placed to offer a solution to the offshore renewable energy (ORE) market that is even greater than the sum of its parts.

Combining great experience to create even greater things.

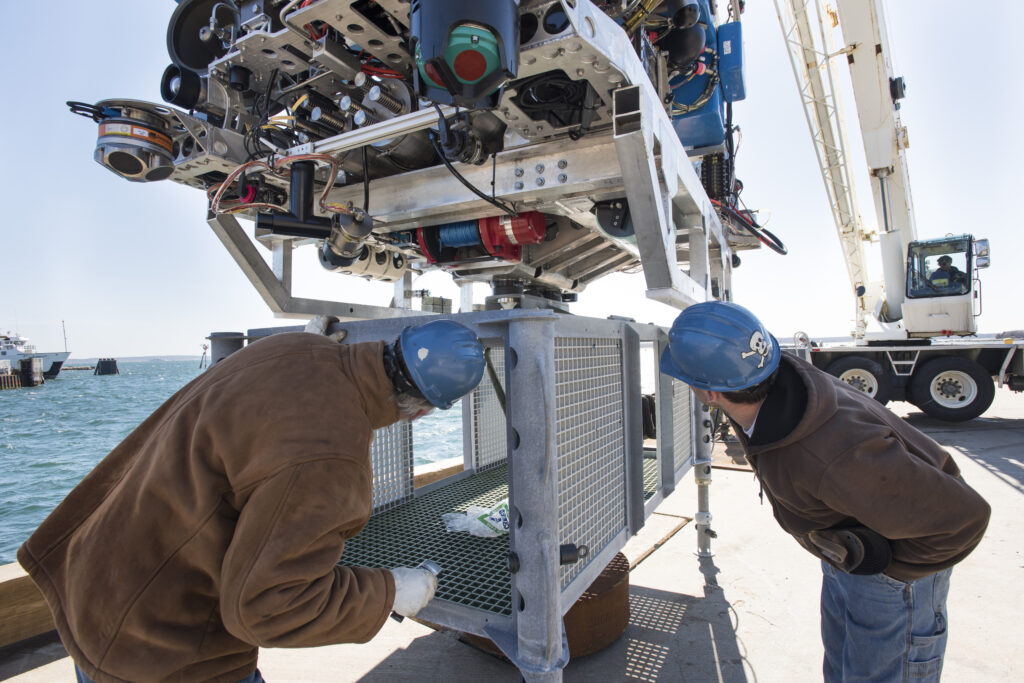

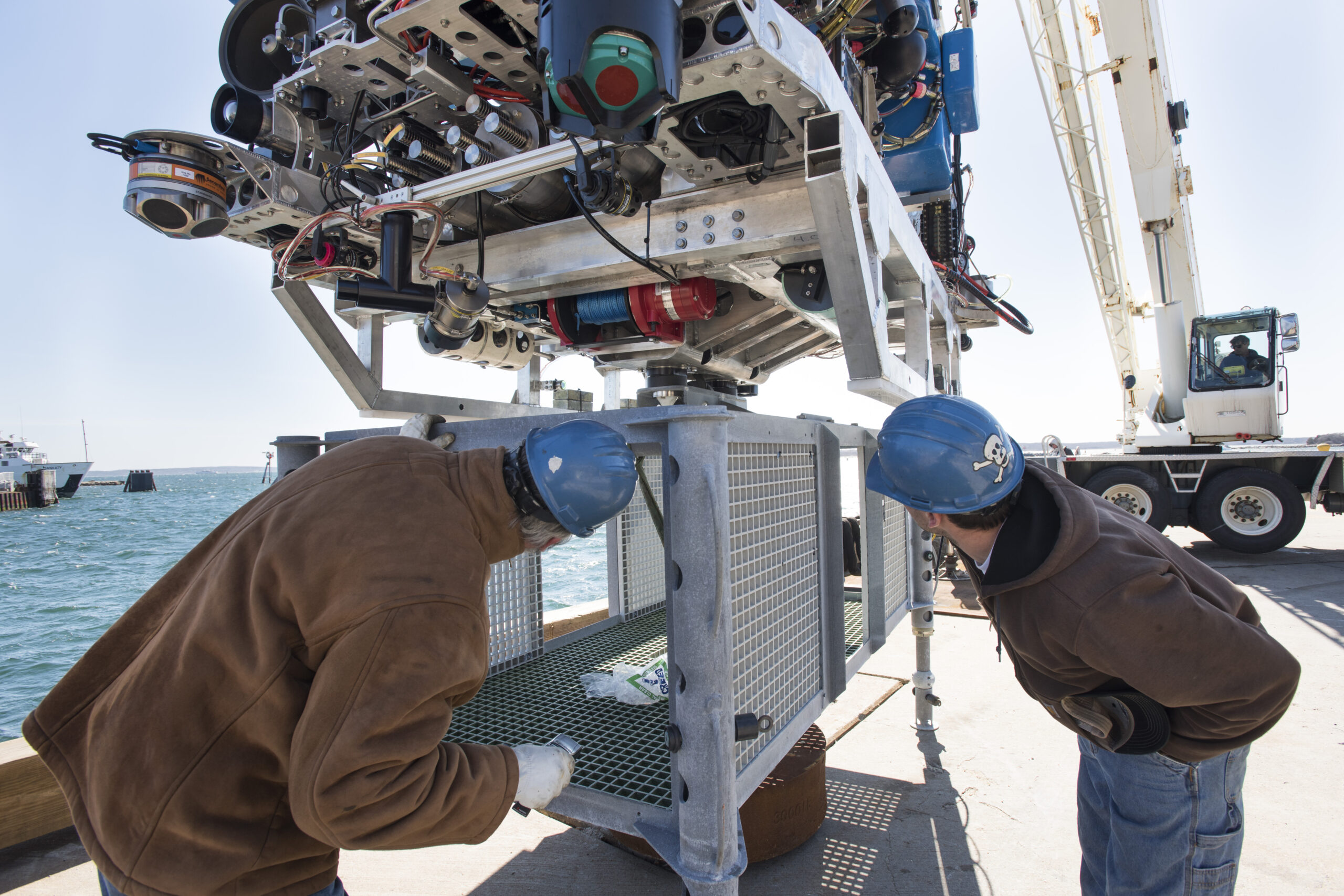

Bringing together their combined expertise at a technology accelerator event at the ORE Catapult Subsea and Marine testing facility in Blyth, Northumberland, UK, Sonardyne, EIVA and Voyis were able to demonstrate the potential of their ORE inspection solution to industry users, vehicle manufacturers and end clients recently.

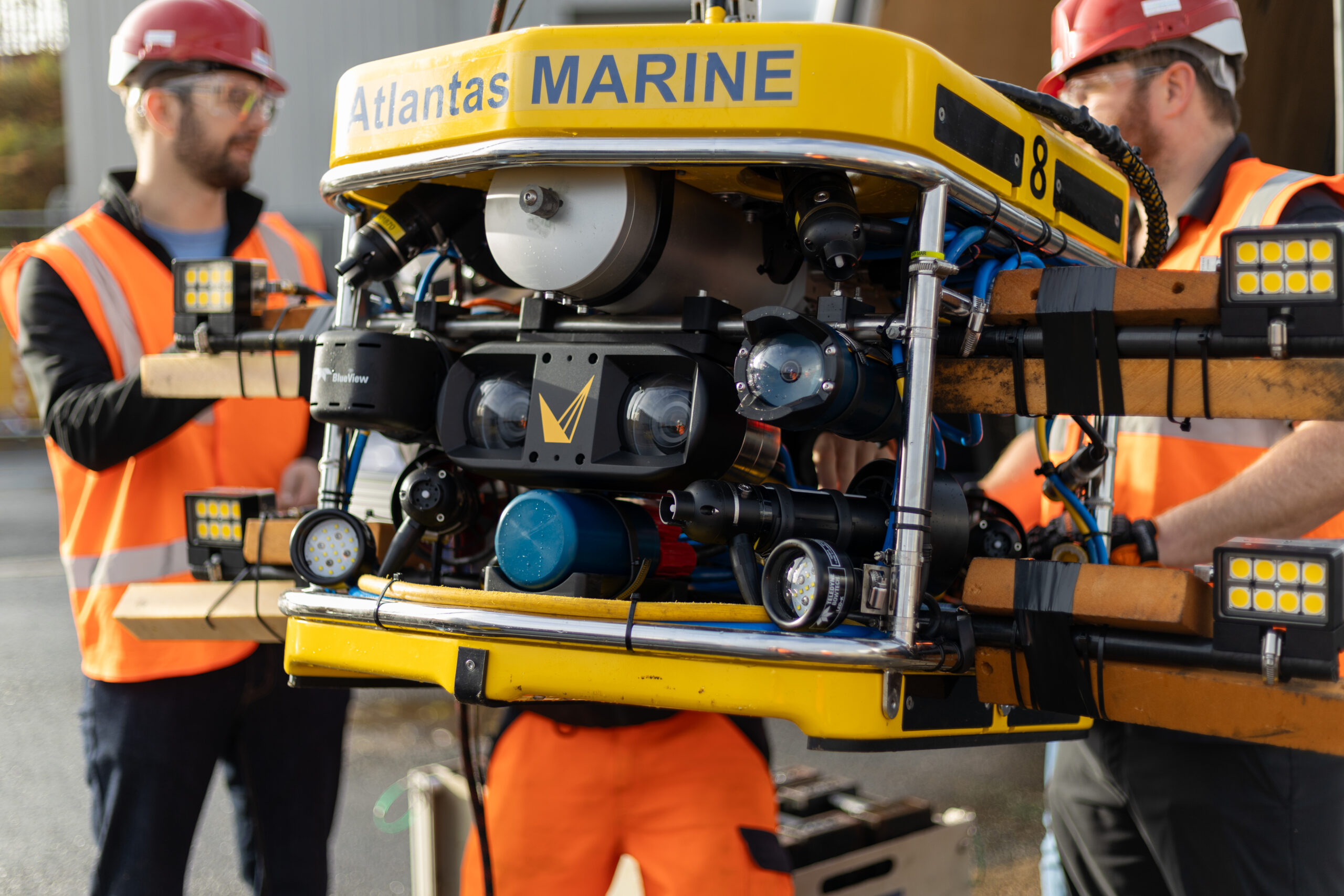

Each company brought its own existing technologies which were integrated, on remotely operated vehicles (ROVs) provided by Atlantas Marine , to demonstrate an even more effective solution for underwater surveying.

During the demonstration, NaviSuite VSLAM leveraged the Discovery Stereo system to enable augmented piloting through real-time 3D point cloud images for quality control, while NaviSuite Mobula provided an end-to-end software solution for acquisition, processing and delivery of data.

Sonardyne SPRINT-Nav Mini

Sonardyne’s SPRINT-Nav Mini provides robust, reliable, navigation for piloting and surveying. It is the world’s smallest hybrid acoustic-inertial navigation system and can be used as an all-in-one vessel and marine robot navigation instrument with performance beyond its size. The SPRINT-Nav Mini eliminates the need for separate sensors, such as AHRS, DVL, INS, and depth sensors. This results in no further calibration requirements, fewer cables and connectors to manage and it is more cost-effective than the four sensors it replaces.

It will work in the most challenging environments and remains unaffected by steel structures such as wind turbine foundations and provides a continuous stream of positions, orientation, velocities, depth and altitude at up to 200 updates per second.

Voyis Discovery Stereo camera

Voyis’ Discovery Stereo camera provides a powerful platform for a vehicle’s subsea vision needs, delivering stills images, video, IMU data and 3D data with a data-centric DDS architecture. Through edge computing, it integrates with EIVA’s visual simultaneous localisation and mapping (VSLAM) software technology to provide real-time 3D reconstruction, ensuring area coverage mapping and augmented piloting. Mounted on the front of the ROV, the Discovery Stereo provided 4K video stream and high-resolution images for both navigation and inspection throughout the demonstration.

EIVA NaviSuite Mobula

EIVA’s NaviSuite Mobula software package provides a complete topside software solution for the ROV, enabling efficient acquisition of data with the Voyis Discovery Stereo and Sonardyne SPRINT-Nav Mini. This software offers unique capabilities for automating remotely operated subsea inspection and surveying operations – using tools for a wide variety of tasks, leveraging the software toolbox of NaviSuite.

Demonstrating the difference.

The technology accelerator event at Catapult provided the perfect opportunity to showcase the possibilities in developing this combined subsea inspection solution. The test dock contains a turbine foundation and various other structures, perfect for subsea navigational and photogrammetry demonstrations.

The ROV was fitted with a SPRINT-Nav Mini at the rear, Discovery Stereo camera at the front and utilised the NaviSuite Mobula and VSLAM software packages to control the ROV movements, represent the operation in a real-time 3D visualisation and pilot view, along with monitoring coverage and inspection data quality.

Once the ROV was launched, focus shifted to the control room where the assembled delegates watched the live 4K video stream from the Discovery Stereo camera as the vehicle navigated the dock.

Whilst its primary navigation and positioning was provided by the SPRINT-Nav Mini, as the ROV navigated and surveyed the subsea structures the Discovery Stereo camera and NaviSuite software combined their capabilities to provide millimetric positioning precision and 3D point cloud detail which was fed back to the control room. A video from the demonstration, giving more information about the technology, can be viewed here.

In real-life operations, these actionable insights could then be used to make immediate decisions about state of the asset, the quality of the data and subsequent actions required from the ROV. Having the capability to make real-time operational decisions greatly reduces the risk of collecting inaccurate data and helps to avoid the associated wasted time and cost.

For Sonardyne, EIVA, Voyis and the wider Covelya Group, this demonstration of synergetic working is just the beginning of our ‘Better Together’ approach. The opportunities for delivering smarter, faster, cleaner and more effective subsea technology solutions from within the group of companies are almost endless.

Pinpointing Precision: Arctia chooses Sonardyne system for subsea surveys

When Finnish state-owned hydrographic services and icebreaking company Arctia need to accurately and reliably position their subsea survey equipment there is only one logical solution.

Arctia provide a wide range of services for Finland’s maritime industry including icebreaking, hydraulic engineering, planning and permit services, fairway maintenance and survey services, hydrographic services and research.

Their services all rely on precise subsea navigation and tracking, especially those using towed survey equipment. This is where Sonardyne come in, Arctia have chosen their Mini-Ranger 2 Ultra Short BaseLine (USBL) system with WSM 6+ transponders for their marine survey services.

Many of their marine surveys are conducted around offshore wind farms where teams of internationally certified hydrographic surveyors and shallow water experts provide tailor-made survey, analysing and planning solutions to meet even the most demanding of customer needs.

Mini-Ranger 2 is one of Sonardyne’s most popular USBL systems, chosen for its small size, value and dependable performance in all underwater environments. It’s the perfect choice for fitting to small survey vessels, moored barges and uncrewed vessels.

For Arctia, it is the perfect partner for towed hydrographic survey equipment such as magnetometers and sidescan sonars used as part of their survey services. With depth ratings of up to 1000 metres and able to operate in temperatures as low as -5 degrees Celsius, it’s ideal for the Baltic Sea and offers the opportunity to upgrade to other versions for depths up to 4,000 metres should Arctia and their customers operate at greater depths in future.

If you have a similar challenge in your subsea navigation and tracking operations, contact us to see how we can help.

Operating a small robotic platform in any marine environment is not without its challenges. Reliability and precision with accurate positioning data are key for safe operations and where repeat inspections or surveys are needed.

The size of the platform may present its own limitations, restricting the size and weight of any payload and therefore the extent of its operational capabilities. Environmental or locational factors may also play a part in the reliability of operations. Most navigational and positioning payloads use magnetic compasses to provide heading. This reliance on magnetic heading makes the platform susceptible to interference from ferrous materials in its surroundings. These could be wind turbine or energy platform monopiles, wreckage or unexploded ordnance (UXO) on the seabed, the presence of vessels / submerged infrastructure in harbours and coastal locations or even just naturally occurring ferrous minerals in the seabed.

These factors introduce heading errors that compromise the supervised autonomous functions of the platform, particularly when following line headings between reciprocal bearings. Even minor heading inaccuracies can cause cumulative deviations over extended missions, leading to imprecise data and potentially requiring time-consuming survey line re-runs.

Any inaccuracies during survey when locating UXOs are particularly unwelcome, by their nature most UXOs are located based on magnetic signature. So, any poor navigation during the wide area or detailed UXO survey can be misleading and potentially dangerous. With repeat inspections of monopiles, for example, ensuring the survey platform returns to the exact same spot on each visit is important to ensure no anomalies or potential problems are missed.

Heading accuracy

0.15°

Regardless of the environment

Depth rating

0

m

Weight in water

0.6kg

“Historically, smaller electric vehicles have been limited in the amount of work they are capable of due to size, power and operational limits presented by weather conditions and surroundings.

Recent iterations of handheld ROVs such as the VideoRay Defender have looked to change what electric ROVs are capable of, while maintaining a platform that is easy to mobilise, operate and maintain. That said, the ROV is only as powerful as the tooling that it holds, so it still requires support from companies such as Sonardyne, to reduce the form factor and weight of their tools and sensors, to enable their integration and deployment offshore.

Atlantas Marine have already been utilising the SPRINT Nav Mini to great success on our Ocean Modules V8 M500 platform, but the latest SPRINT-Nav U will allow us to go further and integrate it onto our VideoRay Defender ROVs, and provide another service that we can offer our customers – a hand-launched ROV, that can be mobilised in as little as half an hour, transported to site in the back of an car” Mark Salter, Senior Project Manager, Atlantas Marine.

“Like the other hybrid navigators in the SPRINT-Nav family, SPRINT-Nav U’s true north seeking gyrocompass means that it delivers reliable subsea navigation even when in close contact with the types of environmental factors outlined above. With its ultra-compact form factor (135mm X 114mm) and a weight in water of just 0.6kg, SPRINT-Nav U gives unrivalled navigation capability to small marine robotic system allowing users to maintain a heading accuracy of 0.15° regardless of environmental factors.

“SPRINT-Nav U has been designed with our customers in mind. We’ve been speaking to them for a number of years about their aspirations for operations with small platforms. With the help of valued customers like Atlantas Marine, our trials have demonstrated a variety of use cases for this new, compact navigator and we’re excited to work on many more innovative uses in future.” Aidan Thorn, Business Development Manager – Marine Robotics, Sonardyne.

Small, light, precise

SPRINT-Nav U is simple to integrate into any marine vehicle along with other payload sensors and uses same field-proven web user interface found on the SPRINT-Nav Mini. Pre-calibration in the factory also means that SPRINT-Nav U is incredibly quick to set up and deploy on site with an alignment time of as little as five minutes, compared to the standard 15-20 minutes of other gyrocompassing inertial navigation systems, making it the world’s fastest aligning hybrid navigator.

“SPRINT-Nav U can turn any marine robot into a survey grade platform. For UXO and asset inspection it drastically improves deliverable data quality. As part of the proven Sonardyne SPRINT-Nav family, customers can be assured of reliable, accurate navigation and positioning every time, no matter the operating environment.” John Houlder, Senior Product Manager, Sonardyne.

“Of particular significance to us, is the work we undertake on offshore wind turbines. With a high AC voltage running through the subsea cabling, and the strong magnetic signatures associated with that, plus the ferrous nature of the turbines themselves, the SPRINT-Nav U allows us to offer our customers a level of accuracy and precision that was previously not possible. It allows us to state with much higher confidence the location of any faults and anomalies, and allows us to repeat inspections, year on year, as we document the changing condition of those faults. With the positioning and control managed through Greensea, we can set up autonomous routes and sea patterns with more accuracy and precision than even before, especially in the environments we most commonly find ourselves.”

Mark Salter, Senior Project Manager, Atlantas Marine.

“Providing improved accuracy when operating in ports and areas where large metallic objects are buried on or beneath the seabed, improves not only the reciprocal bearings of the lanes the ROV is flying, but feeds a more accurate heading into the navigation solution which is streamed to the surveyor.

Beyond seabed surveys, the ability to maintain a stable heading while piloting a compact inspection-class ROV through culverts with rebar or complex subterranean tunnels is a key advantage. It reduces the need for frequent heading corrections and ensures precise navigation when traversing long distances. This ultimately enhances the quality of deliverables for our clients, providing us with a competitive edge when deploying our equipment.”

Richard Stanley, Project Leader, Atlantas Marine