Author: Duncan Rigg, Vessel Systems – Technical Lead

Have you ever considered how the quality of the equipment you attach your transceiver to affects your transceiver’s performance?

We have, which is why over the last 25 years we have been developing and perfecting our own deployment machines to suit most vessel types. These have been designed to provide survey grade rigidity, maximising system accuracy.

Through-Hull deployment

Through-Hull deployment

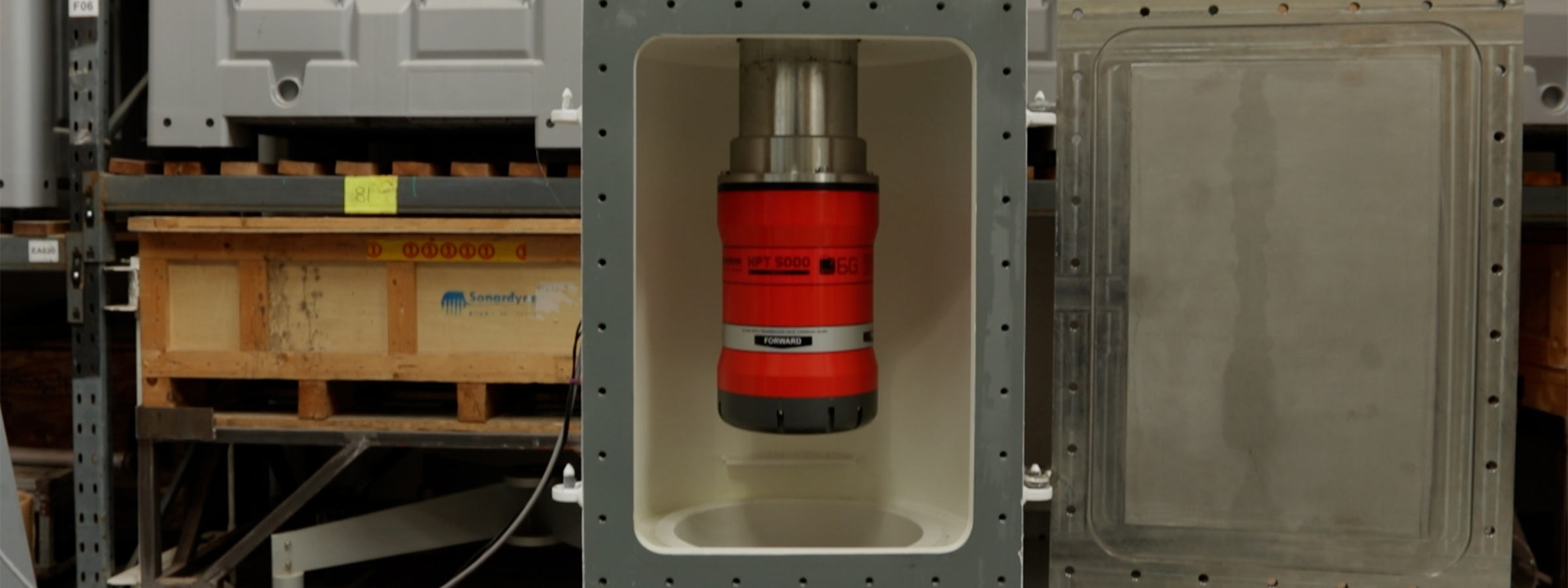

There are four types of deployment machine available, the first of these is our through-hull deployment machine. It consists of a hydraulically operated pole, a sealed bearing section and a sea chest service section with inspection door. The whole machine sits on a gate valve with the whole arrangement sitting on a through-hull penetration pipe.

Owing to its more complex nature and size, this set up is typically integrated into new build vessels. However, many have been retrofitted when there’s space.

Offshore Support Vessel Through-Hull deployment

The second type of deployment machine is a reduced size version of the through-hull deployment machine, specifically designed for offshore support vessels (OSV) where space is at a premium.

As a result, this deployment machine is intrinsically lower cost – without compromising on performance. The through-hull deployment machine uses an Inconel clad steel pole, for fantastic corrosion resistance. The OSV machine uses stainless steel pole providing good corrosion resistance, but at a lower cost.

Both machines can be controlled from a main control unit, local control unit or an optional bridge control unit as well as through Ranger 2 and Marksman. Both machines offer the option to have remote gate vale actuation.

These machines can be supplied to whatever type approval is required for your vessel, as well as type approved DN350 and DN500 gate valves.

Going over the side

When cutting the hull is not an option we have our over-the-side deployment pole. This is the perfect solution for vessels of opportunity or smaller support vessels.

Made from high grade steel, the highly rigid pole has been designed with a helical strake running up its submerged section. This reduces the chance of vortex induced vibration, which can degrade system performance and lead to pole failure.

The pole is made from 3m sections allowing it to be adjusted in length for the vessel it’s being installed on. Typically, it’s supplied in a 9m or 12m length, with a deck mount pivot for easy access to the transceiver. For vessels where the drop between the deck and the water line is greater than 3m a hull-mount pivot can be supplied.

To protect the pole from corrosion it is made from hot dip galvanize steel coated in a two-part marine epoxy.

The deployment and recovery is left down to the vessel but this is typically done using the vessel’s crane or a third party winch fitted to the over-the-side pole.

Through-tube deployment

Through-tube deployment

Our final type of deployment system is our through-tube deployment pole. This variation on the through-hull deployment machine has been designed for vessels where gate valves or over-the-side deployment are not viable or practical, due to size and space.

Just like the over-the-side pole, the through-tube pole also uses a helical strake to reduce the effect of drag and vibration. The same steel finishing processes are used here too. And, the through-tube pole can normally be retrofitted to most vessels.

If you’d like to know more about our deployment machine options or to discuss a particular project, please get in touch.

If you missed our video on deployment machine options, you can always watch it here.