Precision depth monitoring for offshore operations

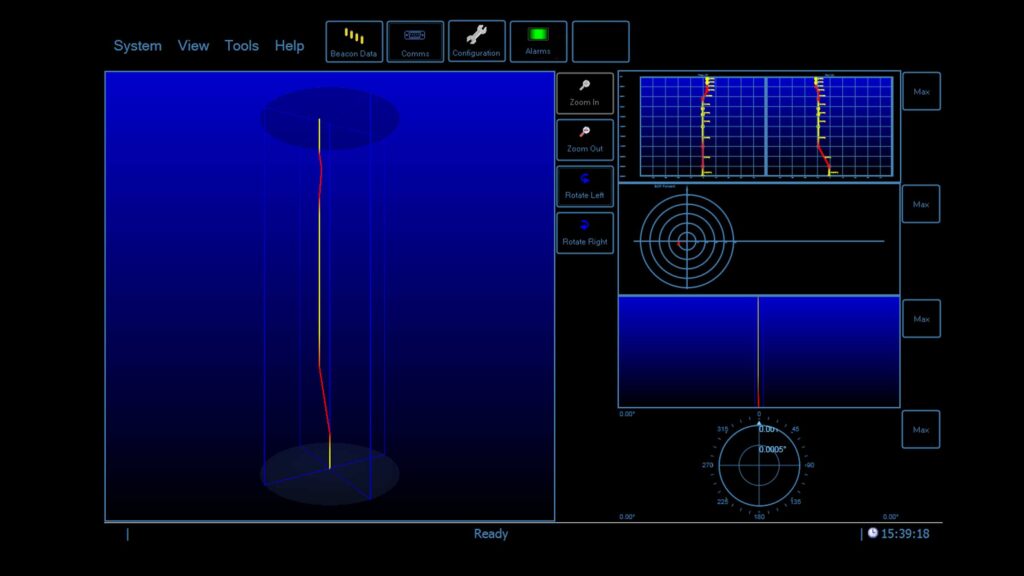

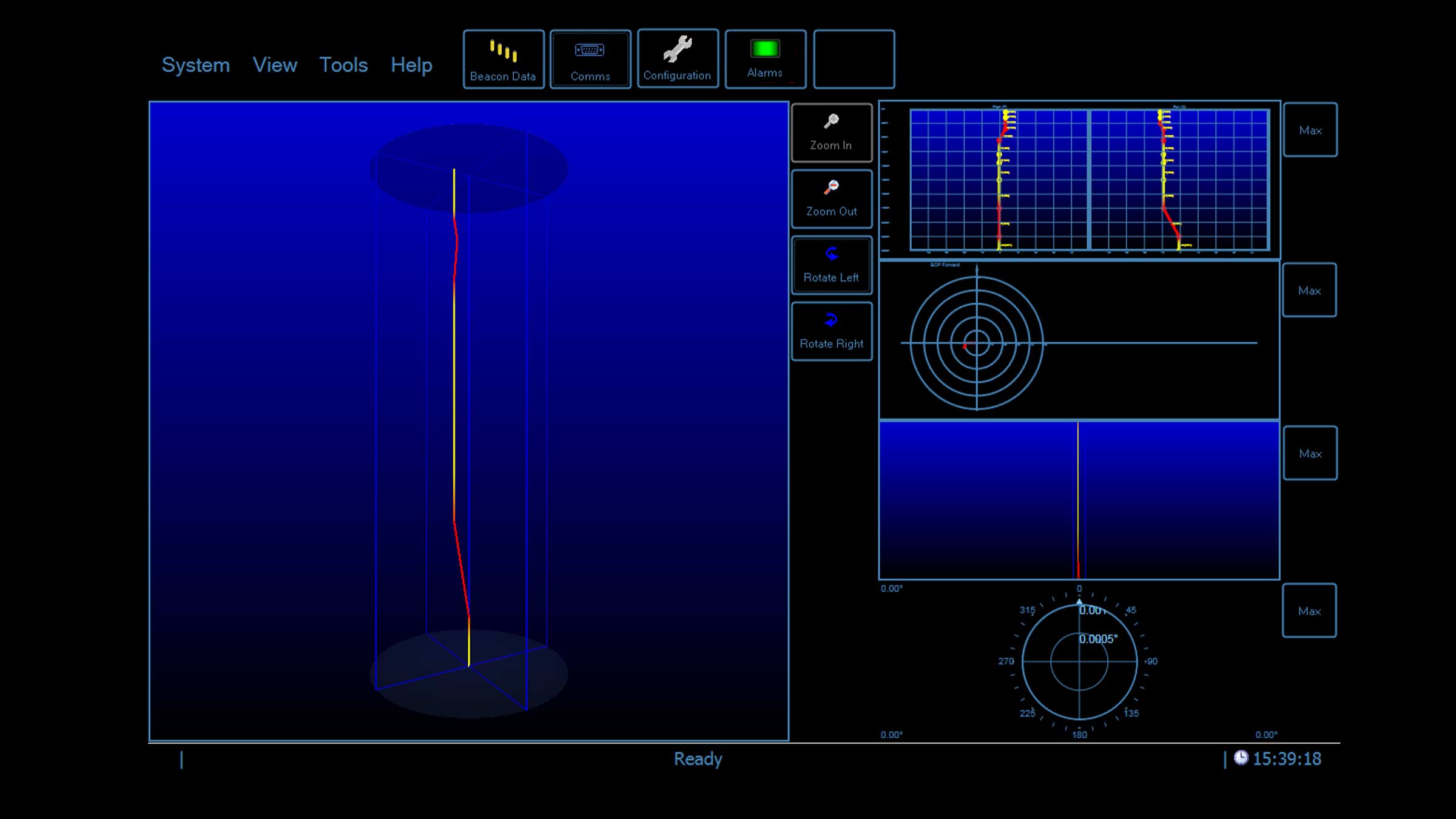

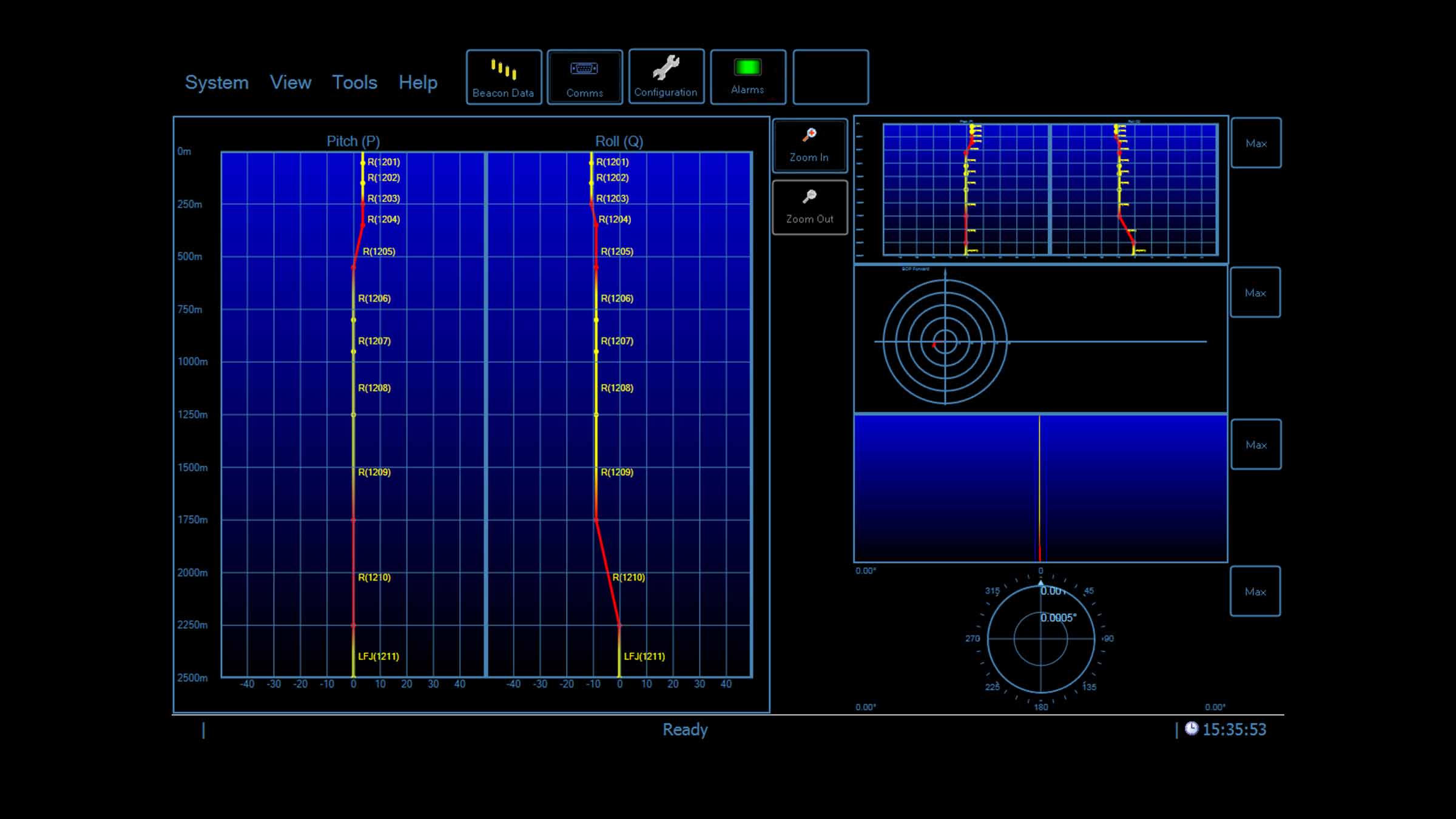

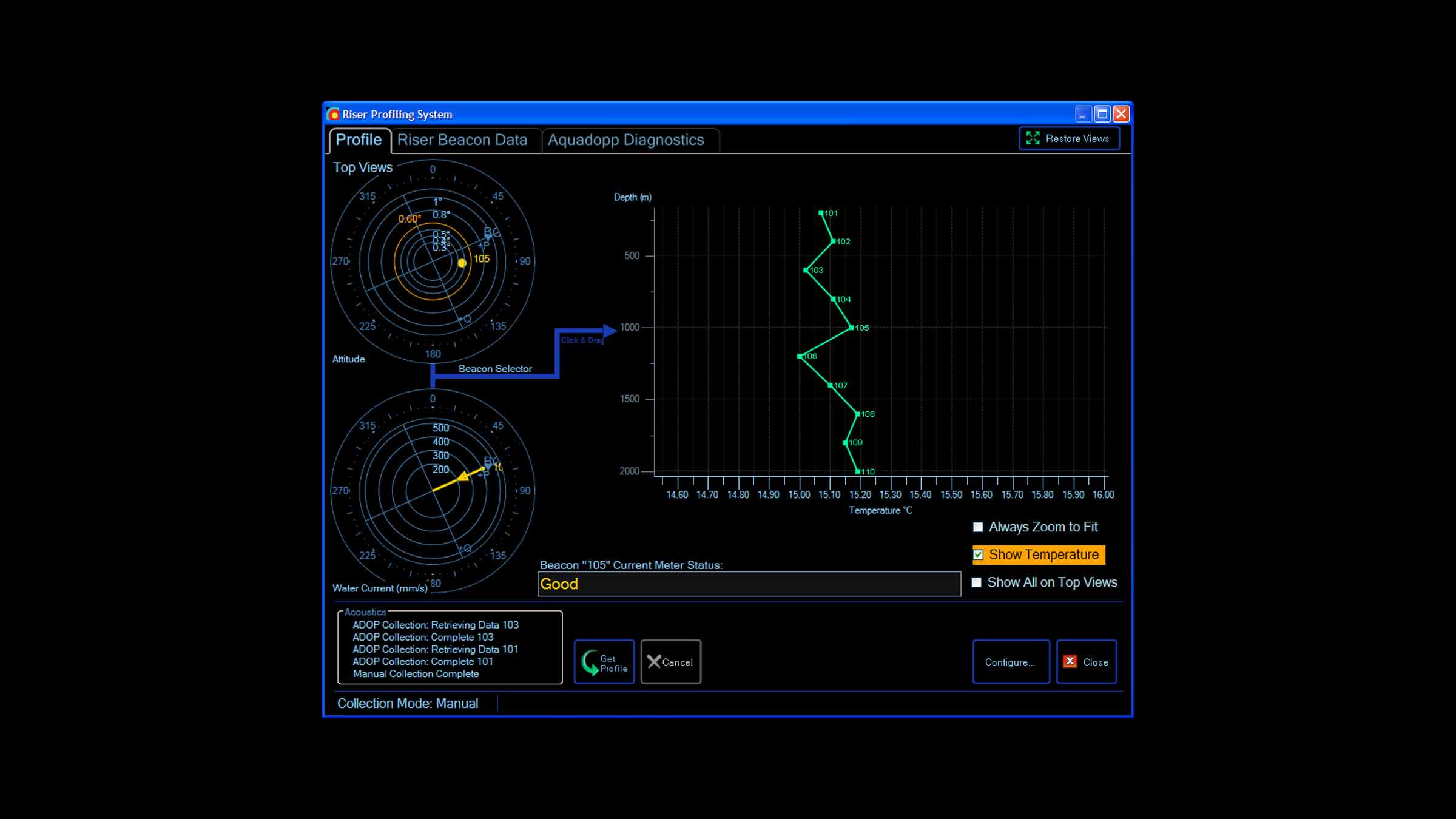

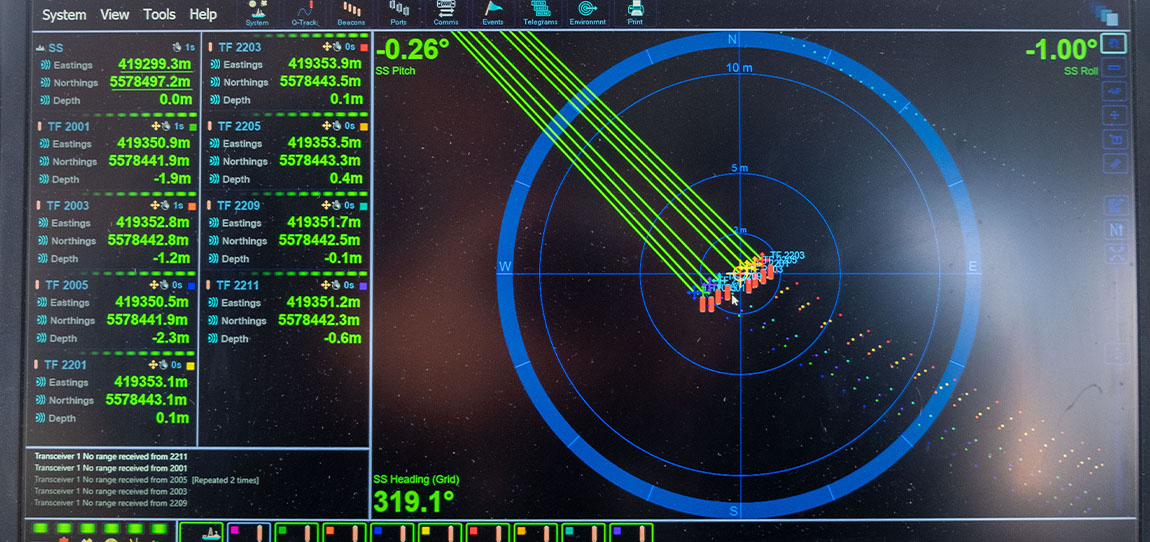

The Riser Profiling system can be used as a standalone, integrated within a Marksman LUSBL acoustic position reference system, or with a third-party integrated monitoring system.

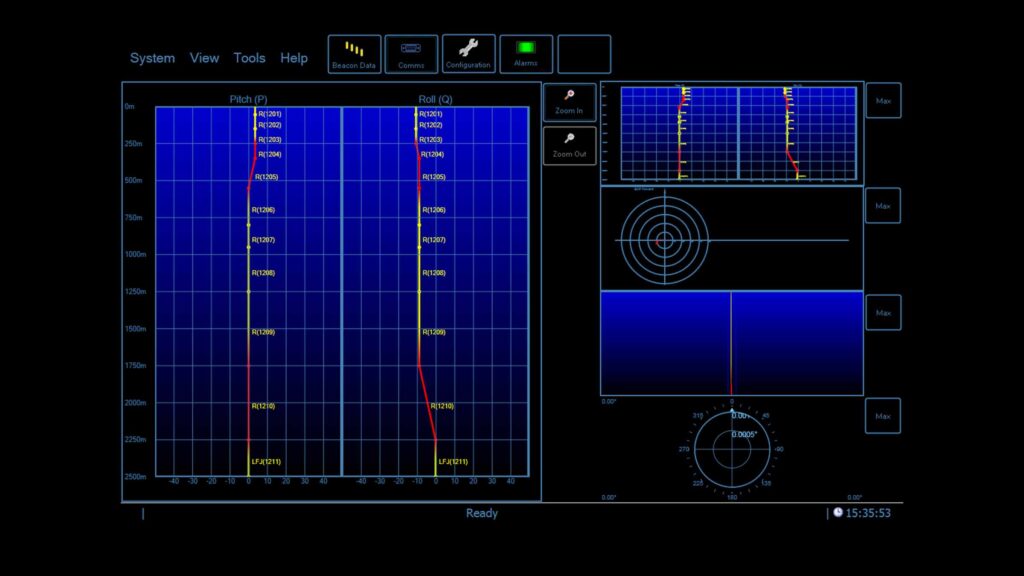

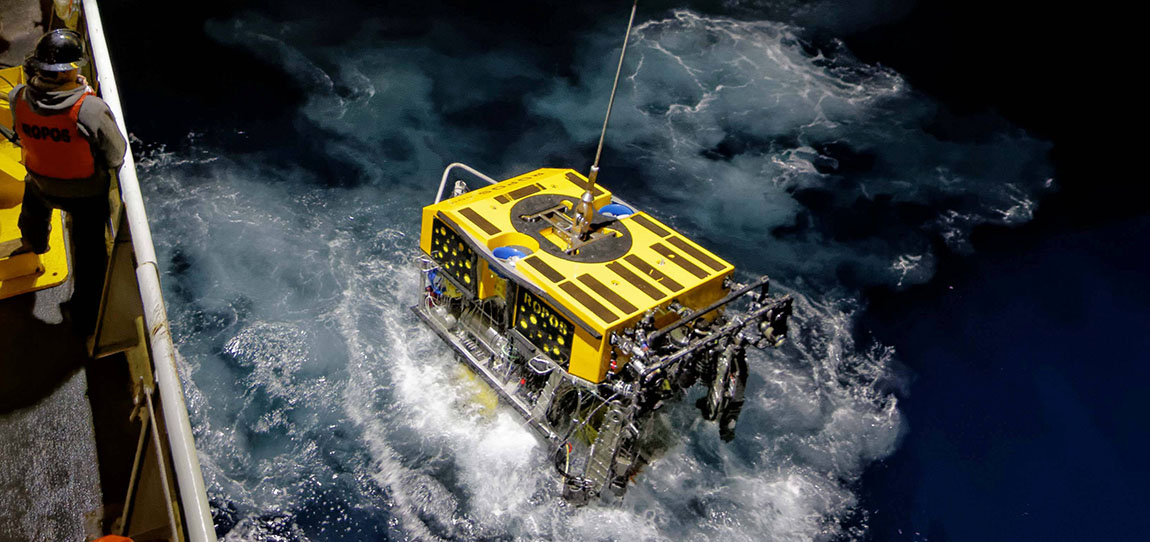

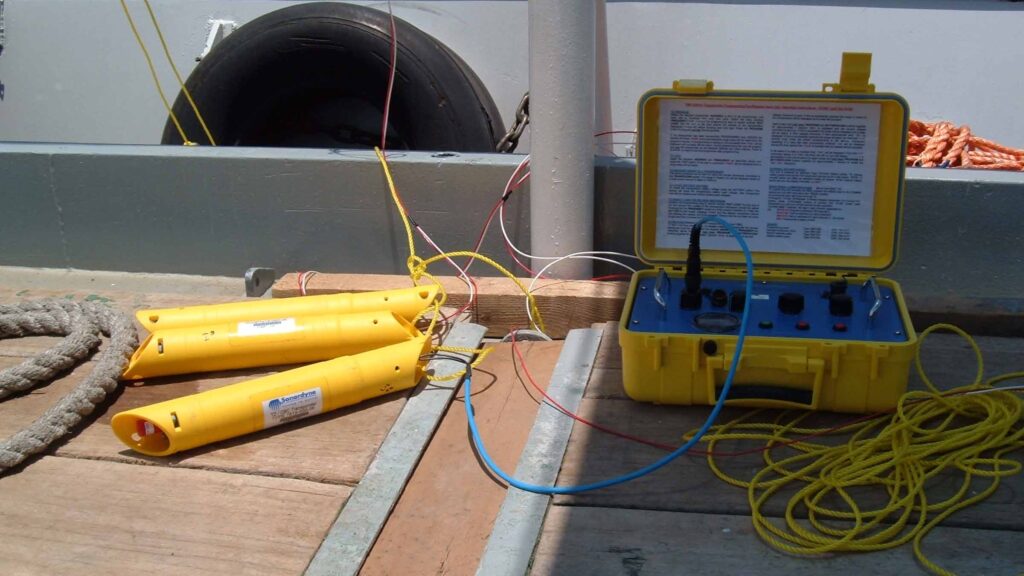

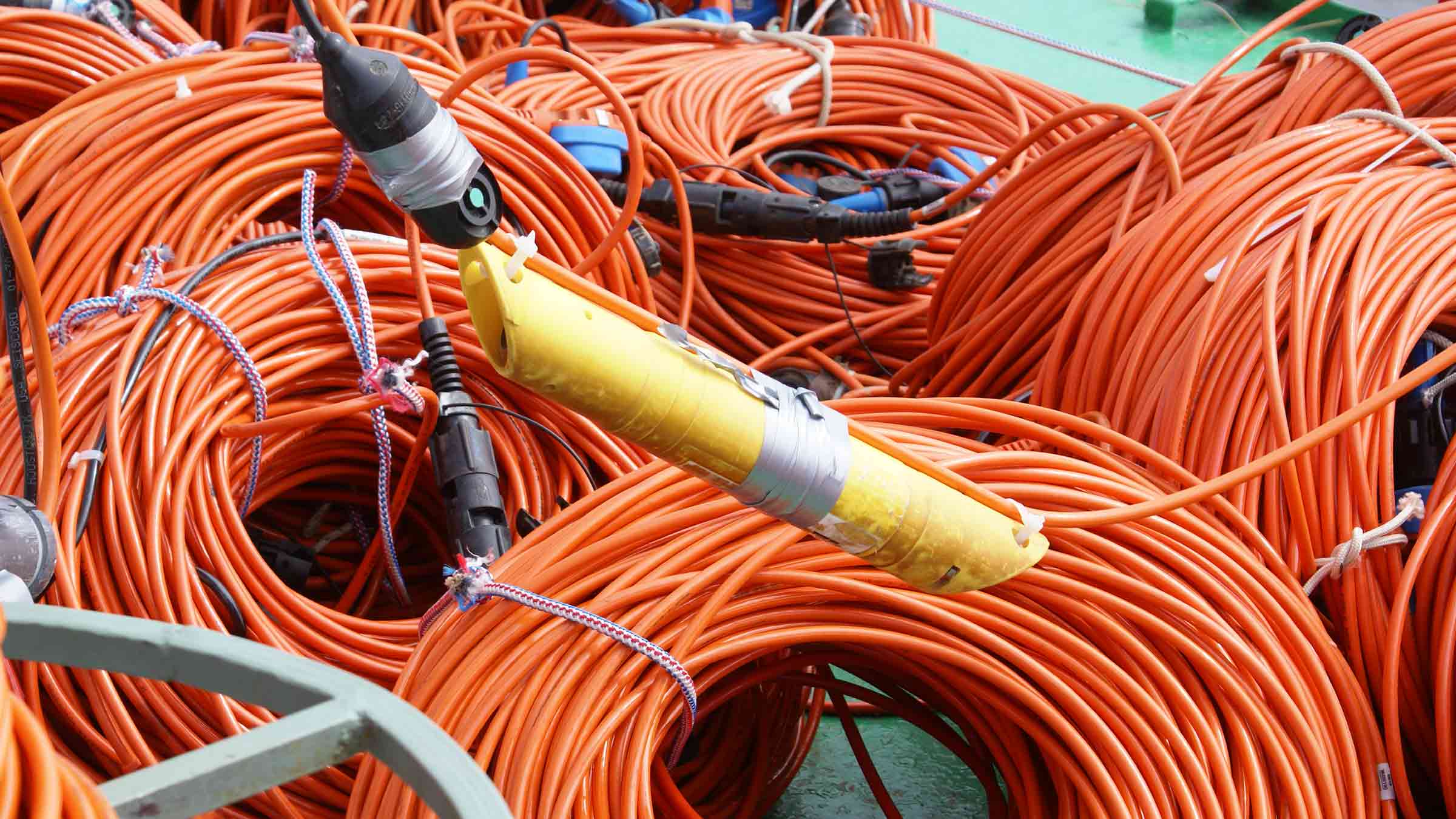

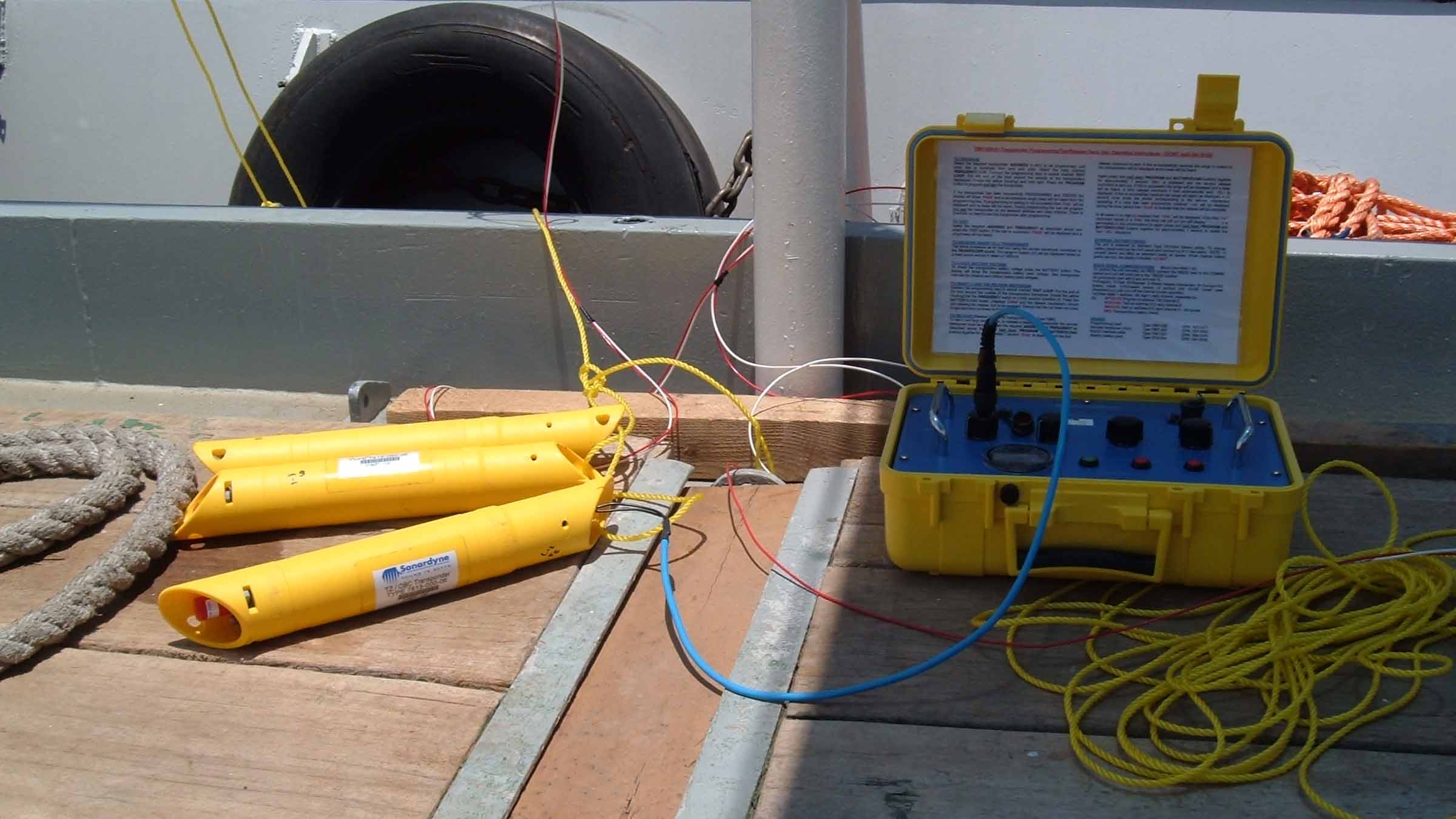

6th Generation (6G®) DPTi or SMART transponders wirelessly mounted along the length of the riser, provide highly accurate data. These are clamped onto the riser during deployment or installed via ROV subsea. Up to ten transponders are mounted on a riser. Each transponder is fitted with the following sensors:

- High-resolution dual axis inclinometer

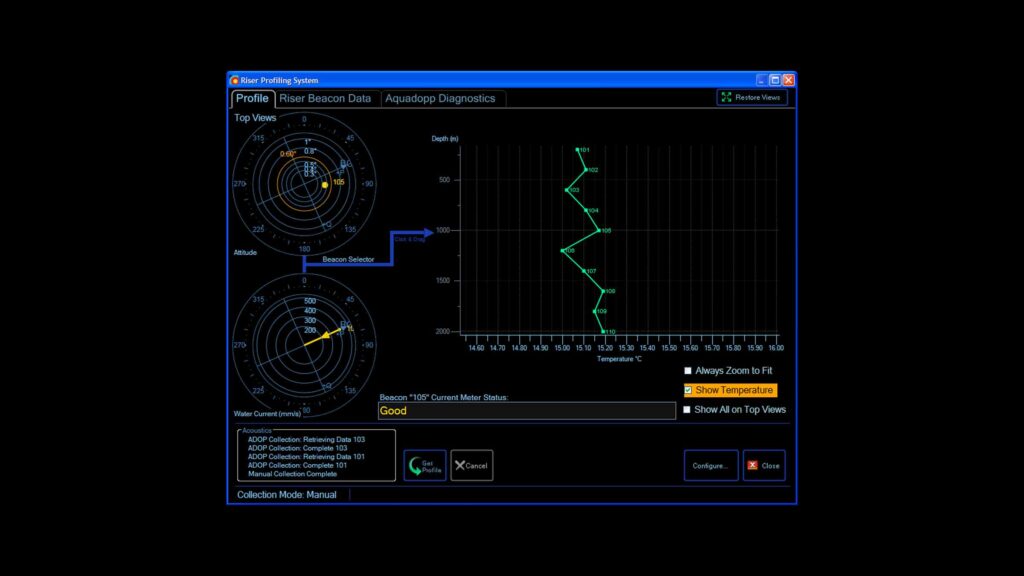

- Water temperature

- Pressure and depth

- Optional single point Doppler current meter (speed, direction)

The gathered data is transmitted wirelessly from the transponders using our Wideband 2 acoustic signals to a transceiver on the vessel, eliminating the need for expensive umbilical cables to fitted up each riser.

At a glance

- Designed for monitoring your riser’s integrity

- Helps prevent critical damage during operations

- Removes need for expensive cables

- 6G hardware and Wideband 2 acoustic delivers robust performance during operations

- User configurable update rates

Advanced monitoring for subsea success

Topside software makes changing monitoring regimes easy. You can even set an alarm to activate when the calculated riser angle exceeds a predefined limit.

At the update rate you choose, inclination, current speed and direction, pressure, temperature measurements are requested from each transponder. All data is processed, logged and displayed graphically and numerically on the topside computer software for your instant analysis. When SMART transponders are used, the data is processed within the transponder and wirelessly transmitted to the vessel’s transceiver.

Specifications

| Rider Profiling System | Equipment Required | |

|---|---|---|

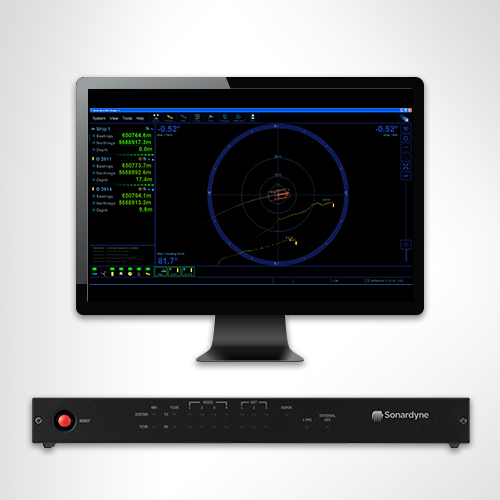

| Topside Computer Hardware | Sonardyne Navigation PC (marine approved) | |

| Operating System | Windows®10 | |

| Acoustic Sensor Interfacing and Time Sync | Sonardyne Type 8098 Navigation Sensor Hub (NSH) | |

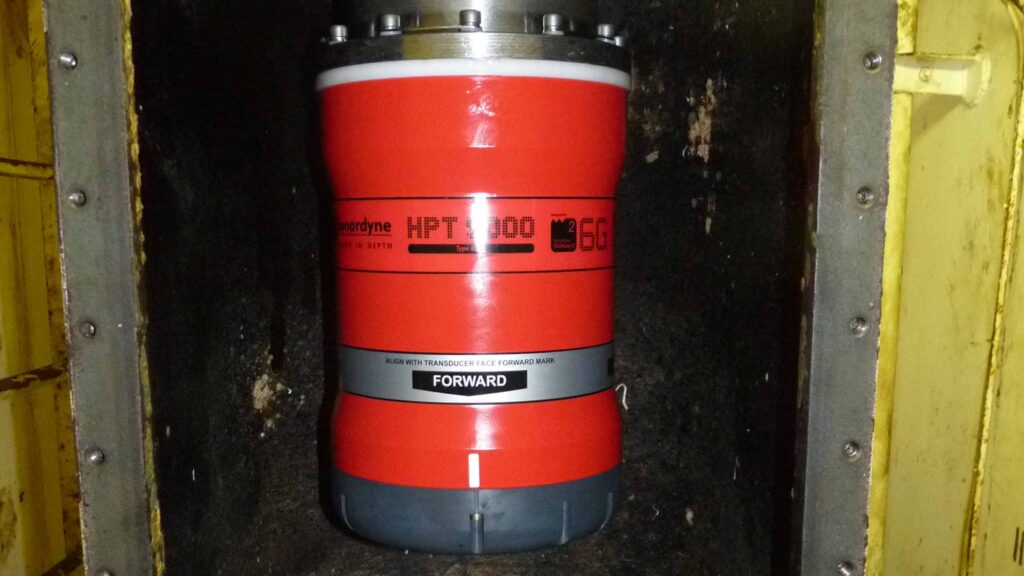

| Vessel Transceiver | Sonardyne Type 8142 HPT (LMF band) | |

| Riser Transponders | Sonardyne Type 8300 DPTi 6 (LMF band) | |

| Sensor Accuracies | Temperature (PRT) | ±0.1°C |

| Pressure/Depth (Strain Gauge) | ±0.01% | |

| Dual Axis Inclinometer (Pitch/Roll) | ±0.05° over 0 – ±15°; ±0.2° over 0 – ±45° | |

| Current/Water Velocity (Single Point Doppler) |

1% of measured value ± 0.5 cm/s |

Datasheets

Support

• Comprehensive and flexible training for system operators

• 24-hour support, whenever and wherever you are in the world

• Custom configured to meet your exact operational requirements

• Systems are manufactured and tested before delivery at our world-class in-house facilities

Design

• Operating depth range 3,000 m (5,000 m)

• Robust two-way communications

• Compatible with all makes of DP system

DPTi 6 at a glance

• High accuracy inclinometer range: ±90°

• Accuracy: 0° to ±15° = ±0.05°; 0° to ±45° = ±0.2°

• Temperature ±0.1°C

• Tilt switch ±30-45°

• Strain gauge pressure sensor ±0.01%

• High precision strain gauge (optional) ±0.01%

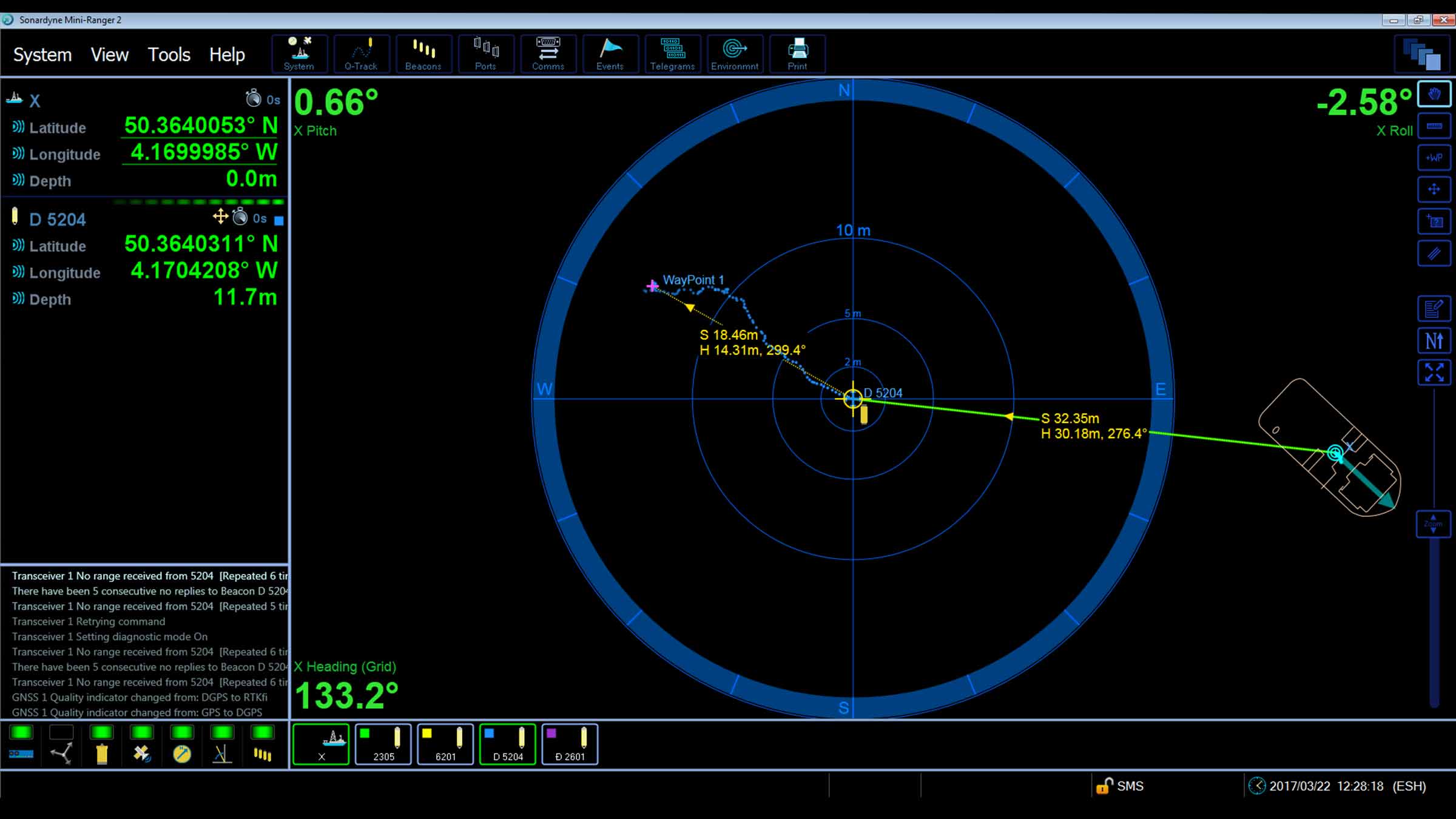

Hardware overview

• Compatt 6 DPTi riser transponder

• Riser Profiling software

• HPT Transceiver

• Marine Computer

• Ethernet Serial Hub (ESH)

• Riser mounting buckets available

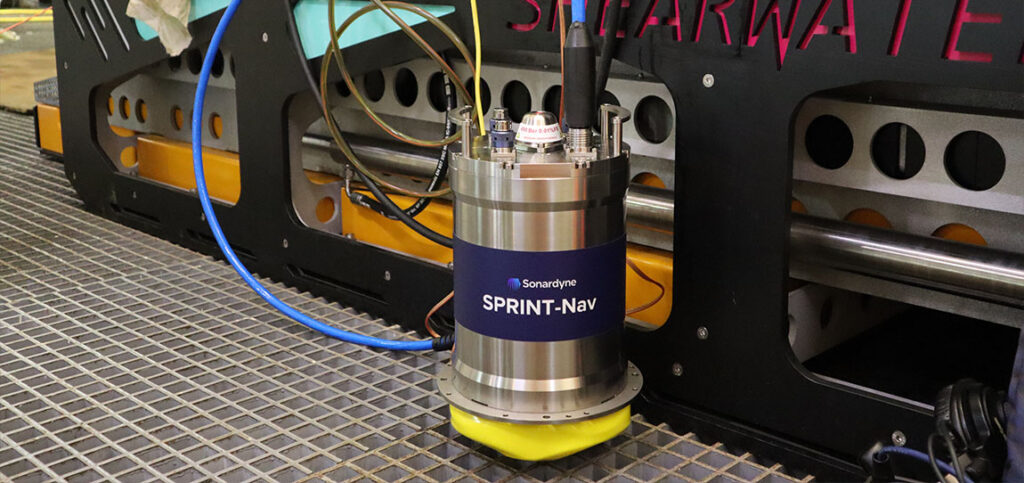

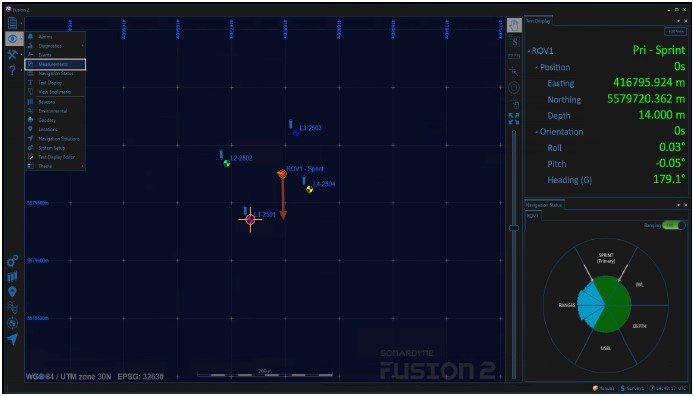

Get the SPRINT advantage

SPRINT gives you:

- Robust performance in challenging subsea conditions

- High-precision outputs for enhanced vehicle control

- Instantaneous start-up without lengthy alignment periods

- Seamless integration with your existing equipment

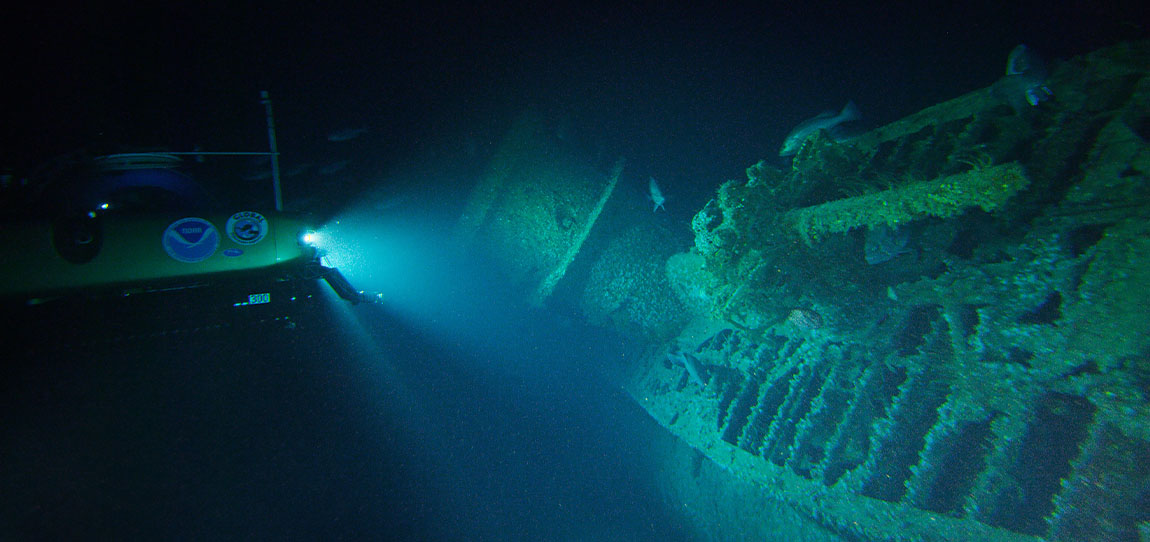

SPRINT optimises acoustic aiding data from USBL, LBL, Doppler Velocity Log (DVL) and pressure sensors, improving position accuracy, precision, reliability, and integrity. It extends the operating limits of your vessel’s USBL and enhances LBL efficiency by enabling sparse seabed transponder arrays. All while reducing operational time and vessel costs.

Choose your SPRINT

- SPRINT 300: Perfect for dual ROV and survey use, standalone ROV guidance, and mid-water station keeping. It’s the most cost-effective subsea INS available, with less than 0.1° Sec Lat Heading accuracy.

- SPRINT 500: Ideal for your demanding multibeam survey operations. Supports tightly integrated sparse LBL range aiding from Sonardyne 6G transponders, with automatic pressure and swell compensation.

- SPRINT 700: Our highest-performance INS system, designed for your most challenging subsea survey tasks. Supports mobile laser mapping and acoustic inertial metrology with tight integration to Sonardyne acoustics.

The technology

Inertial navigation is inherently self-contained and robust with very good short term accuracy, but it can drift over time. Therefore, the SPRINT INS is supported by complementary acoustic positioning to provide long term accuracy and robustness. This significantly reduces operational delays during periods of challenging subsea acoustic conditions such as aeration and noise. The precision and update rate of the output allows greater subsea vehicle control and makes SPRINT suitable for ROV station keeping.

SPRINT shares a hardware platform with our Lodestar AHRS and runs both AHRS and INS algorithms concurrently. This allows instant INS start or restart upon receiving a position update, eliminating the lengthy ‘alignment’ period common in other systems. The system monitors AHRS and INS orientation separately to assess its health. All calculations are performed internally, protecting against communication issues. The system maintains a 15-day backup of navigation and raw data on an onboard SD card, while topside software concurrently logs all data, ensuring data integrity.

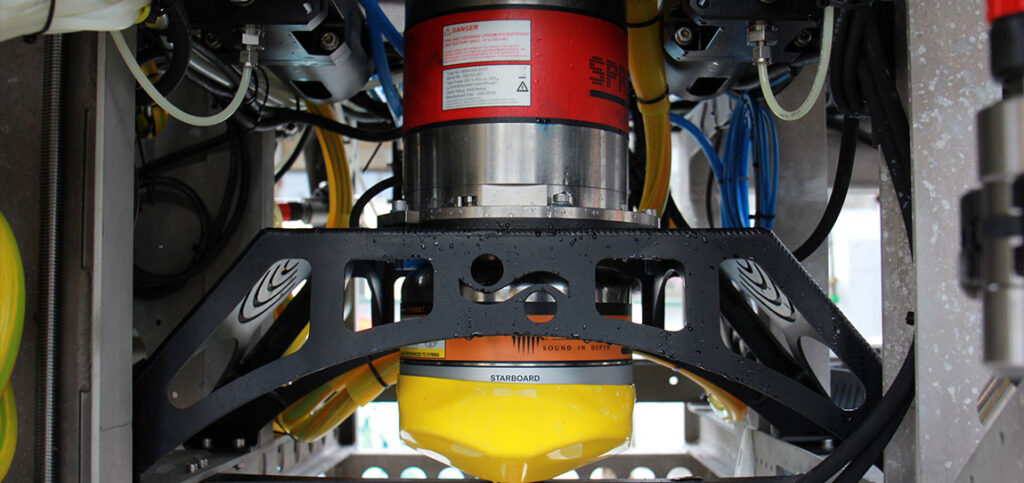

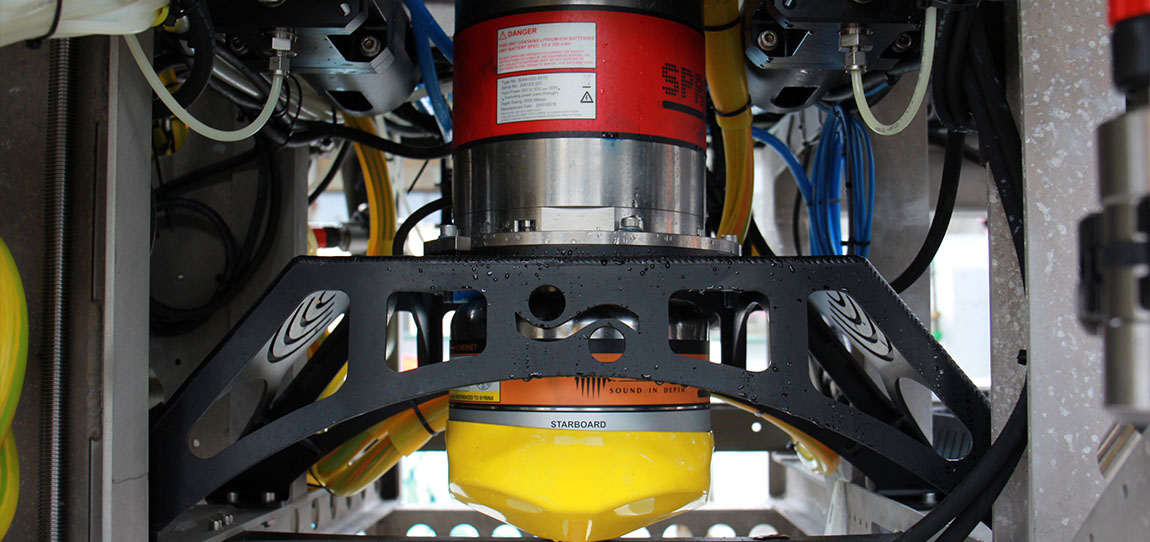

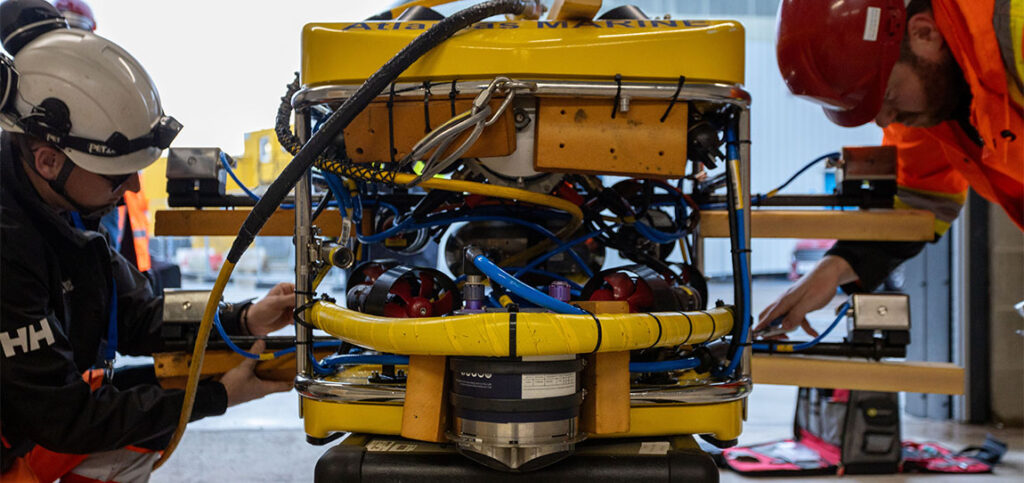

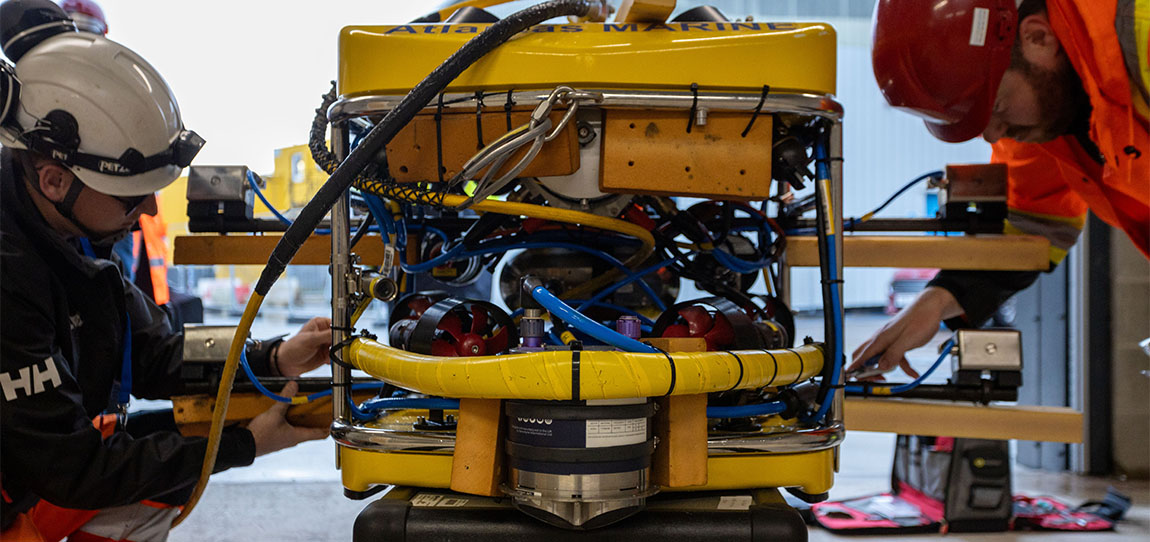

DVL and AHRS/INS

Our Syrinx DVL provides tight beam-level aiding to SPRINT, giving superior positioning performance even with partial beam availability. Standalone 3rd generation SPRINT and Syrinx DVL can be joined together for pre-calibrated, interchangeable use, or combined into the compact SPRINT-Nav unit. This integrated solution, optionally including an internal pressure sensor, is suitable for various ROV and survey tasks. The combined unit features depth-rated water blocks for each transducer to protect the internal components and when supplied together typically doesn’t require re-export licensing, simplifying your shipping logistics.

Performance

• Heading accuracy 0.02° (secant latitude)

• 0.01° Pitch/Roll accuracy

• 0.03% Typical survey accuracy

• USBL/LBL aided: 4.5 x precision improvement

• USBL/LBL and DVL aided: 6 to 13 x precision improvement

• INS Aiding supported: USBL, depth, DVL, zero velocity, manual position, LBL (position), GNSS

Design

• Titanium housing construction

• Provides concurrent AHRS and INS capability for dual use

• In field remote performance upgrades: Yes

• Onboard data storage and battery backup to ride through brown outs

• Navigation outputs: position, depth, attitude, velocity, accelerations, rotations

Ownership

• Warranty: 1 year return to Sonardyne service centre

• ITAR Controlled: No

• UK Export Licence: Yes

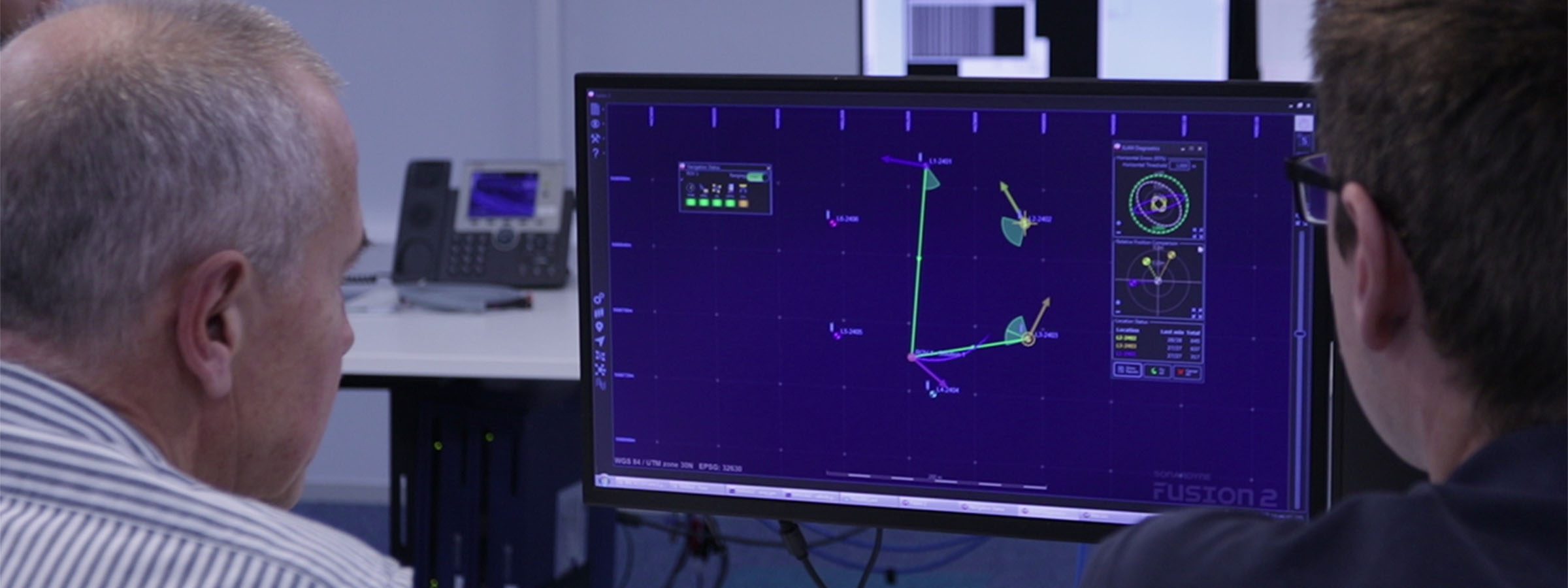

• What’s in the box: SPRINT, mounting plate, test lead and cable tail, Fusion 2 software

Typical applications

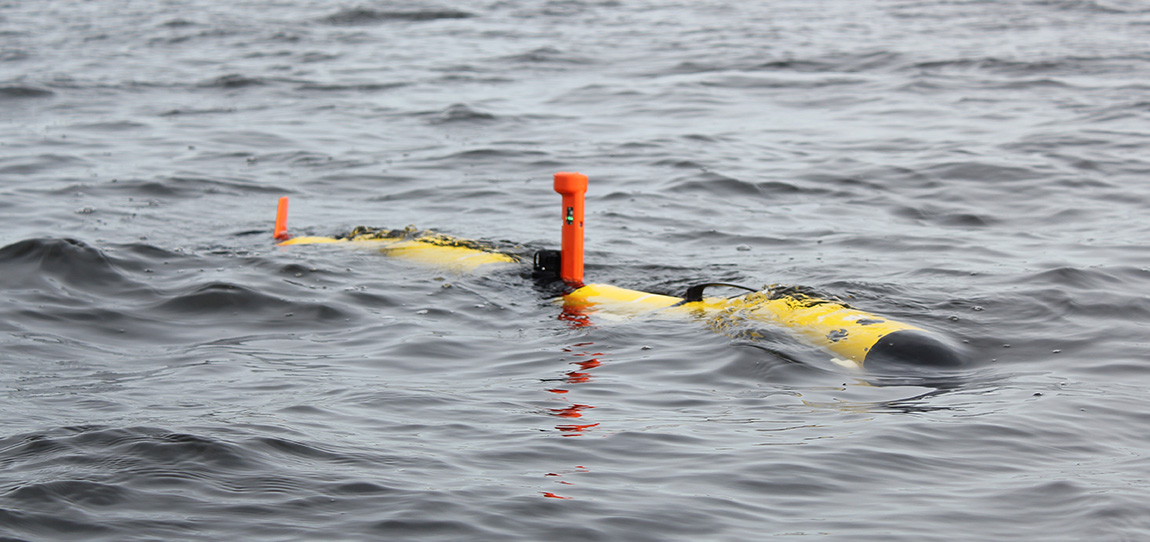

• ROV and towfish positioning

• Hydrographic and multibeam survey

• ROV DP including mid-water station keeping

• Offshore construction; trenching, as-laid, OOS, touchdown monitoring, structure placement

Specifications

| Performance | SPRINT 300 | SPRINT 500 | SPRINT 700 | |

|---|---|---|---|---|

| Heading | 0.05° secant latitude | 0.04° secant latitude | 0.02° secant latitude | |

| INS initialisation | Instantaneous | Instantaneous | Instantaneous | |

| Roll and pitch | 0.01° | 0.01° | 0.01° | |

| INS aiding supported | USBL, Depth, DVL, Zero Velocity, Manual Position, LBL, GNSS | USBL, Depth, DVL, Zero Velocity, Manual Position, LBL, GNSS | USBL, Depth, DVL, Zero Velocity, Manual Position, LBL, GNSS | |

| USBL/LBL aided | 3x precision improvement | 3.5x precision improvement | 4.5x precision improvement | |

| USBL/LBL and DVL aided | 3 to 7 x precision improvement | 4 to 10 x precision improvement | 6 to 13 x precision improvement | |

| LBL/DVL aided | 3 cm confined area, 20 cm wide area (dynamic) | 3 cm confined area, 20 cm wide area (dynamic) | 3 cm confined area, 20 cm wide area (dynamic) | |

| DVL aided | Typical survey | 0.05% | 0.03% | 0.02% |

| Distance from origin | 0.15% | 0.10% | 0.08% | |

| DVL aiding loss/drift | 1.2 m over 1 minute, 5 m over 2 minutes |

0.8 m over 1 minute, 3.2 m over 2 minutes |

<0.5 m over 1 minute, 2 m over 2 minutes |

|

| Station keeping | <1 m over 24 hours (Syrinx DVL) | <1 m over 24 hours (Syrinx DVL) | <1 m over 24 hours (Syrinx DVL) | |

| Power | ||||

| Power requirement | 20–50 V dc, 15 W nominal (35 W maximum) | 20–50 V dc, 15 W nominal (35 W maximum) | 20–50 V dc, 15 W nominal (35 W maximum) | |

| Power pass through | 3x for external aiding sensors (up to 3 A per sensor) | 3x for external aiding sensors (up to 3 A per sensor) | 3x for external aiding sensors (up to 3 A per sensor) | |

| Internal battery backup | Li-ion/5 minutes | Li-ion/5 minutes | Li-ion/5 minutes | |

| Data/Comms | ||||

| Data storage | 8 GB internal memory | 8 GB internal memory | 8 GB internal memory | |

| Serial ports/protocol | 4x RS232 or RS485 | 4x RS232 or RS485 | 4x RS232 or RS485 | |

| Other ports | Ethernet, 4x Triggers | Ethernet, 4x Triggers | Ethernet, 4x Triggers | |

| Output rate | Up to 100 Hz | Up to 100 Hz | Up to 100 Hz | |

| Mechanical | ||||

| Connector options | 4x Seacon/Seanet 1x Seacon/Seanet |

4x Seacon/Seanet 1x Seacon/Seanet |

4x Seacon/Seanet 1x Seacon/Seanet |

|

| Mechanical construction | Titanium | Titanium | Titanium | |

| Dimensions (diameter x height) |

4,000 m (Seacon) | 205 x 260 mm | 205 x 260 mm | 205 x 260 mm |

| 6,000 m (Seacon) | 205 x 280 mm | 205 x 280 mm | 205 x 280 mm | |

| 4,000 m (Seanet) | 205 x 250 mm | 205 x 250 mm | 205 x 250 mm | |

| Weight in air/water | 4,000 m | 18.5/11.5 kg | 18.5/11.5 kg | 18.5/11.5 kg |

| 6,000 m | 22/14 kg | 22/14 kg | 22/14 kg | |

| Environmental | ||||

| Depth rating | 4,000/6,000 m | 4,000/6,000 m | 4,000/6,000 m | |

| Operating temperature | -20 to +55°C | -20 to +55°C | -20 to +55°C | |

| Storage temperature | -20 to +60°C | -20 to +60°C | -20 to +60°C | |

| Shock rating | 22 g, 11 ms half sine | 22 g, 11 ms half sine | 22 g, 11 ms half sine |

Frequently asked questions

How to mount and extract an ISO image

SPRINT, SPRINT-Nav, Lodestar and Lodestar-Nav troubleshooting

How to calculate the heading accuracy of a SPRINT

How to use Fusion 2 LBL and INS dongles

Can I power my subsea instruments with Lodestar or SPRINT?

How do I mate and calibrate a SPRINT or Lodestar to my Syrinx DVL?

How sparse is a sparse LBL array?

What cables do I need for my SPRINT?

How do I mate and calibrate a DVL to my SPRINT?

What software and firmware is compatible with SPRINT and Fusion 2 Systems?

What’s the difference between FOG and RLG?

What does Vehicle and IMU frame of reference mean?

ROV operational procedure for SPRINT-Nav

Can I input an external depth sensor into SPRINT or SPRINT-Nav?

How to plan my sparse LBL array (guidance note)

How do I calibrate my sparse LBL array?

How do I set up SPRINT-Nav in Fusion 2?

How to interface Ranger 2 into a 3rd party survey system

STP files

Software and firmware

Software and control hardware

Top tips

Datasheets

Manuals and quick start guides

Designed and manufactured entirely in the UK, Syrinx is a class leading DVL for surface and subsea vehicles, available in two frequencies: 600 kHz or 400 kHz for higher altitude tracking up to 230 m. Syrinx variants combine high resolution and high altitude tracking, in single, easy to install navigation instruments. Its adaptive bottom lock technology provides consistency and reliability over challenging and changing topography, working at an altitude higher than 85% of the world’s subsea infrastructure. This reduces the amount of time a vehicle must dive on free inertial.

If your mission requires water profiling, Syrinx’s highly capable ADCP mode enables both navigation and profiling without the need for separate instrument, saving you cost and payload.

When tightly integrated with Sonardyne’s SPRINT INS, unmatched DVL-aided navigation can be achieved. This allows for enhanced performance through optimisation of beam-level data passed between Syrinx and SPRINT to aid velocity prediction and outlier rejection, with positioning able to continue even if one or two DVL beams are unavailable. For the ultimate integration Syrinx and SPRINT are also available as a single combined unit with integral pressure sensor. SPRINT-Nav is one of the smallest inertial DVL instruments available on the market suitable for almost any ROV and survey task.

Why Syrinx?

- Unmatched Versatility: Use Syrinx as a DVL, ADCP, or both simultaneously. You decide how to harness its power.

- Deep-Water Performance: Maintain solid bottom lock up to 230 m, with 4,000 m depth rating as standard.

- Adaptive Technology: Our smart bottom lock ensures reliable navigation across varied seabed types.

- Dual-Frequency Options: Choose between 400 kHz for extended range or 600 kHz for high resolution.

- Seamless Integration: Syrinx works harmoniously with our SPRINT INS for unparalleled navigation accuracy.

- Efficiency: Combine navigation and water profiling in one instrument, saving you space and resources.

- Reliability: Individually replaceable transducers to minimise downtime.

- Adaptability: Available in 4,000 m, 6,000 m and OEM versions to suit your specific needs.

- User-Friendly: Web-based System Manager for easy configuration and control.

- Compatibility: Fits existing mounting arrangements and supports various data formats for smooth integration.

Dive deep, control smart

Syrinx runs an embedded system manager using a web browser, eliminating the need to install dedicated PC software. This allows configuration and testing of Syrinx prior to deployment, control during subsea operations and visualisation of the navigation data.

The hardware and vehicle interfacing are easy to install, set up and use. It’s compatible with DVL/ADCP mounting arrangements from other vendors so you shouldn’t need to modify your subsea vehicles to upgrade to Syrinx. PD0, PD3, PD4, PD6, PD13 telegrams are supported for integration to third party navigation systems.

A 4,000 m rated titanium housing is supplied as standard to meet the requirements of work-class ROVs. 6,000 m and OEM (no housing) versions are also available.

Syrinx’s transducers have been designed, built and tested in-house to provide maximum performance, and can be individually replaced, reducing ownership costs and repair time. The entire array is water blocked meaning that should damage occur to the transducer array, the unit’s electronics are isolated from water ingress.

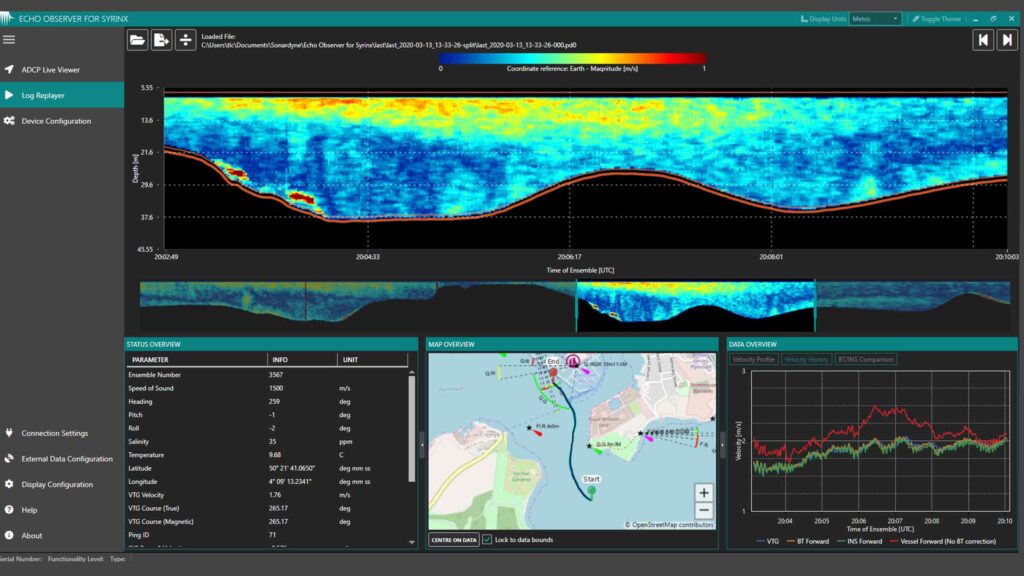

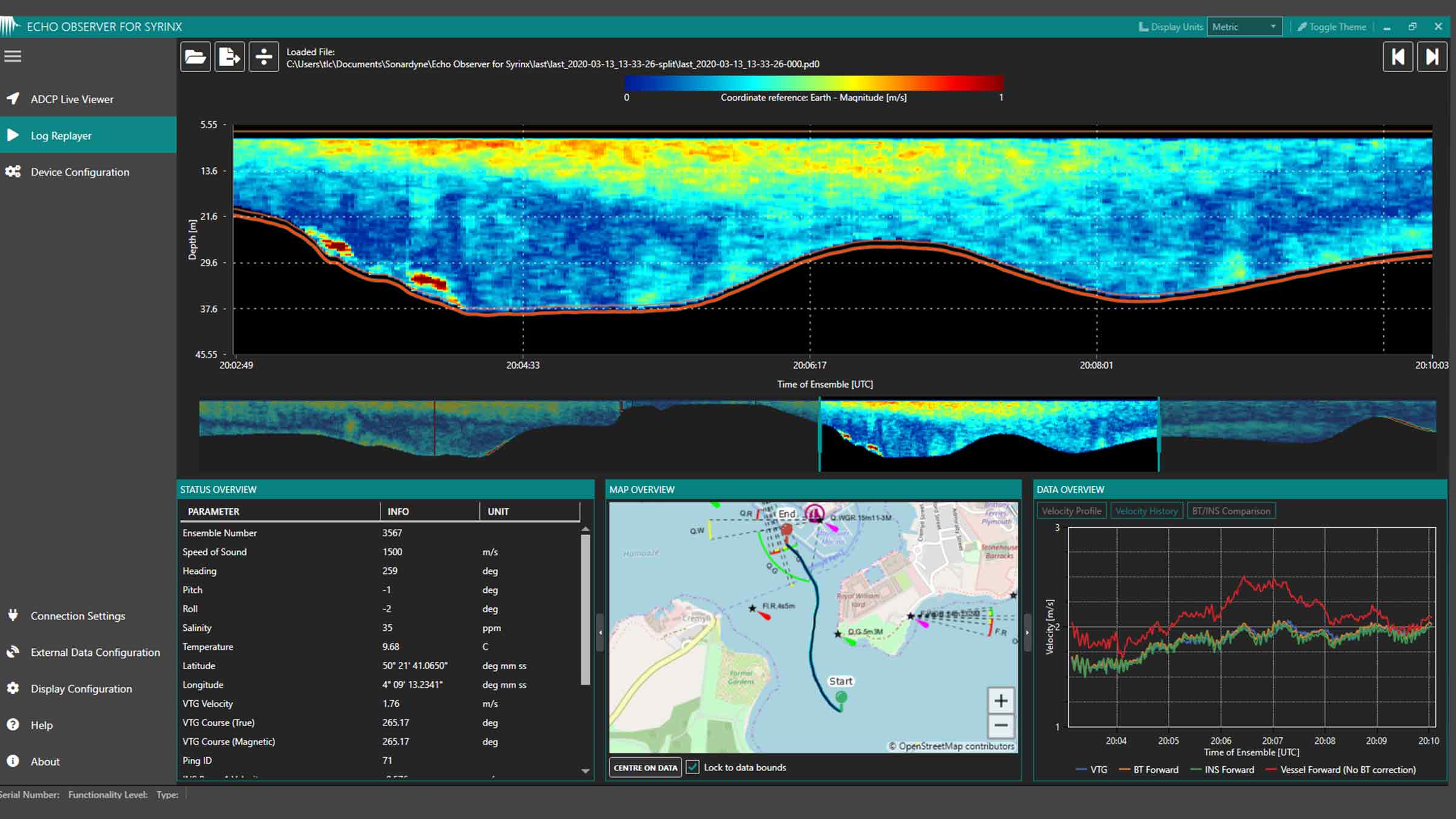

Echo Observer for Syrinx (EOS)

EOS is a software application for Syrinx and SPRINT-Nav systems which allows ADCP data to be viewed, quality controlled, logged and then exported. This standalone application is compatible with Windows 7 or 10 and requires only modest processing resources.

EOS provides an intuitive interface to Syrinx, allowing the device to be configured over Serial port or Ethernet with a quick setup procedure for ADCP measurements. You can immediately view the profile data and make any necessary adjustments before committing to a long-term deployment.

Once initial data inspection has been completed, EOS provides the link to the onward data processing chain: Industry-standard PD0 data can be exported as comma-separated variable (CSV) files, ideal for importing into Excel or Matlab for analysis and post-processing. The exported PD0 data can be tailored to match your analysis needs, such as specific portions of the water column, or a favoured frame of reference.

Specific sections of the PD0 data can be omitted in CSV export if they are not relevant to your analysis, reducing file size and therefore processing time. Echo Observer for Syrinx is included with the ADCP functionality upgrade for both Syrinx and SPRINT-Nav.

Experience the Syrinx DVL advantage

Whether you’re navigating an AUV through complex underwater terrain or precisely positioning an ROV for critical operations, Syrinx provides the accuracy and reliability you need. Our adaptive technology keeps you on track over challenging topography, reducing reliance on inertial navigation.

Ready to transform your underwater operations? Let’s collaborate to integrate Syrinx into your systems and unlock new possibilities in subsea exploration and work. Connect with our team today!

Performance

• 0.4 /230 m min/max altitude

• 0.4–120 m ADCP profile range

• >10 m/s velocity range (DVL)

• 0.01cm/s velocity resolution (DVL)

• Up to ±8.4 m/s ±0.4% of measured value (ADCP along-beam)

Design

• Titanium housing as standard; OEM option

• Replaceable transducers; water block array

• Onboard web UI for setup and configuration.

• Dedicated software for ADCP features

• Max 204 mm x 225 mm, 8.2 kg weight in water (6,000 m version)

Ownership

• Warranty: 1 year return to Sonardyne service centre

• ITAR Controlled: No

• UK Export Licence: Not required

• What’s in the box: Syrinx DVL/ADCP and QuickStart guide, EOS software (optional)

Acosutic

• 400 or 600 kHz frequency

• 4-beam array @ 30 degree angles

• Up to 25 kHz DVL ping rate

• Up to 4 Hz ADCP ping rate (optional mode)

Specifications

| Feature | 8275-4531/6531 600 kHz | 8275-4561 400 kHz | |

|---|---|---|---|

| Operating Frequency | 600 kHz | 400 kHz | |

| Bottom Velocity – Single Ping Precision (Standard Deviation @ 1 m/s) | ±0.22 cm/s | ±0.28 cm/s | |

| Long Term Accuracy | ±0.12% ±0.1 cm/s | ±0.22% ±0.1 cm/s | |

| Minimum/Maximum Altitude | 0.4/175 m | 0.4/230 m | |

| Velocity Range | >10 m/s | >10 m/s | |

| Velocity Resolution | 0.01 cm/s | 0.01 cm/s | |

| Data Output Rate | 25 Hz maximum | 25 Hz maximum | |

| Water Reference Velocity | Accuracy | ±0.2% ±0.1 cm/s | ±0.2% ±0.1 cm/s |

| Layer Size | Selectable | Selectable | |

| Minimum/Maximum Range | 0.4/80 m | 0.4/120 m | |

| ADCP | Profiling Range | 0.4–80 m | 0.4–120 m |

| Velocity Range & RMS (Along Beam) | Up to ±5.6 m/s ±0.4% of measured value | Up to ±8.4 m/s ±0.4% of measured value | |

| Maximum Number of Cells | 255 | 255 | |

| Maximum Ping Rate – ADCP | 4 Hz | 4 Hz | |

| Maximum Ping Rate – DVL + ADCP | 2.5 Hz | 2.5 Hz | |

| Beam Width | ±1.0° | ±1.3° | |

| Beam Angle | 30° | 30° | |

| Transmit Source Level (dB re 1 µPa @ 1 m) | 217 dB (maximum) | 217 dB (maximum) | |

| Sensors | Temperature | -5 to 40°C | -5 to 40°C |

| Pitch/Roll (Optional) | ±0.5° | ±0.5° | |

| Pressure (Optional) | ±0.1% full scale | ±0.1% full scale | |

| Configuration (Array) | 4-beam array @ 30° beam angles | 4-beam array @ 30° beam angles | |

| Communication and Logging | Communications | Dual RS232, multi-port Ethernet (TCP & UDP) | Dual RS232, multi-port Ethernet (TCP & UDP) |

| Trigger Inputs | 3–12 V rising or falling edge configurable | 3–12 V rising or falling edge configurable | |

| Internal Logging | 32 GB internal memory | 32 GB internal memory | |

| Output Telegrams | Sonardyne proprietary, PD0, PD3, PD4, PD6, PD13, SDDBT Simultaneous telegram output |

Sonardyne proprietary, PD0, PD3, PD4, PD6, PD13, SDDBT Simultaneous telegram output |

|

| Voltage (dc Input) | 24 V (±10%) | 24 V (±10%) | |

| Average Power (Typical) | 10 W nominal | 10 W nominal | |

| Depth Rating | 4,000 or 6,000 m array | 4,000 or 6,000 m array | |

| Operating Temperature | -5 to 55°C | -5 to 55°C | |

| Storage Temperature | -20 to 55°C | -20 to 55°C | |

| Mechanical Construction | Titanium | Titanium | |

| Connector Type | Subconn | Subconn | |

| Dimensions (Height x Diameter) | 4000 m | 189 x 225 mm | 189 x 225 mm |

| 6000 m | 204 x 225 mm | n/a | |

| Weight in Air/Water | 4000 m | 12.0/9.1 kg | 11.3/8.5 kg |

| 6000 m | 14.4/10.9 kg | n/a |

Frequently asked questions

What is PD0?

What is a DVL and how does it work?

How do I mate and calibrate a DVL to my Lodestar?

How do I mate and calibrate a SPRINT or Lodestar to my Syrinx DVL?

What interference might I get between Syrinx DVL and the other acoustic equipment on my vehicle?

What is the maximum seabed slope that I can still bottom track?

How to correct for speed of sound

Can I externally trigger Syrinx DVL?

What is the maximum rate that I can ping?

What are the maximum and minimum velocities that Syrinx DVL can detect?

What are the maximum and minimum altitudes that Syrinx DVL will operate?

How do I mate and calibrate a DVL to my SPRINT?

How do I install a firmware update to Syrinx DVL?

How to download files from Syrinx DVL

DVL mounting considerations for ROVs and AUVs

What DVL messages are supported?

SPRINT-Nav Maintenance Schedule

STP files

Software and firmware

Top tips

Manuals and quick start guides

Technical bulletin

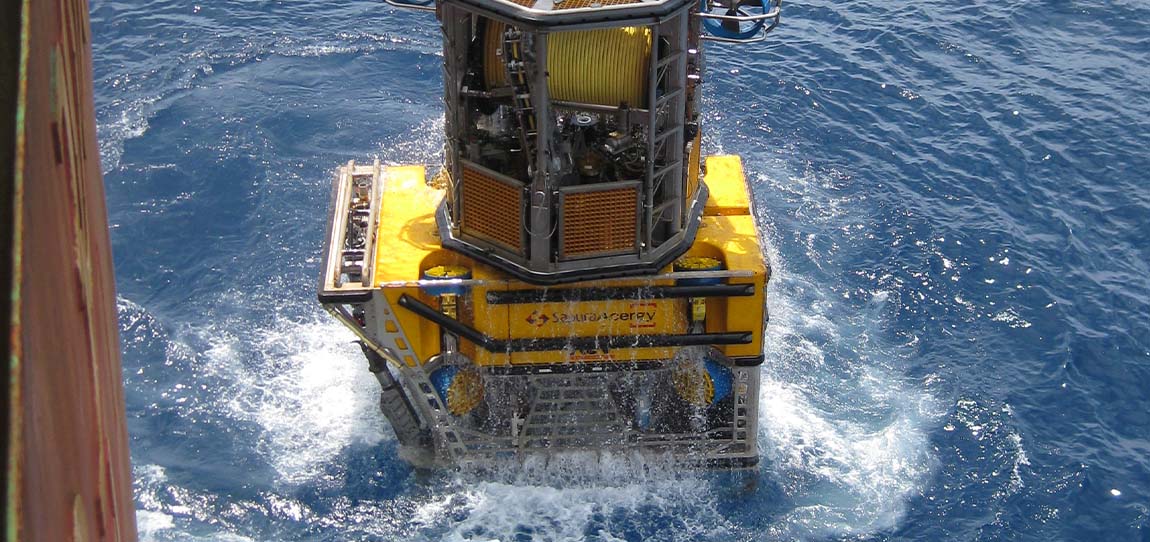

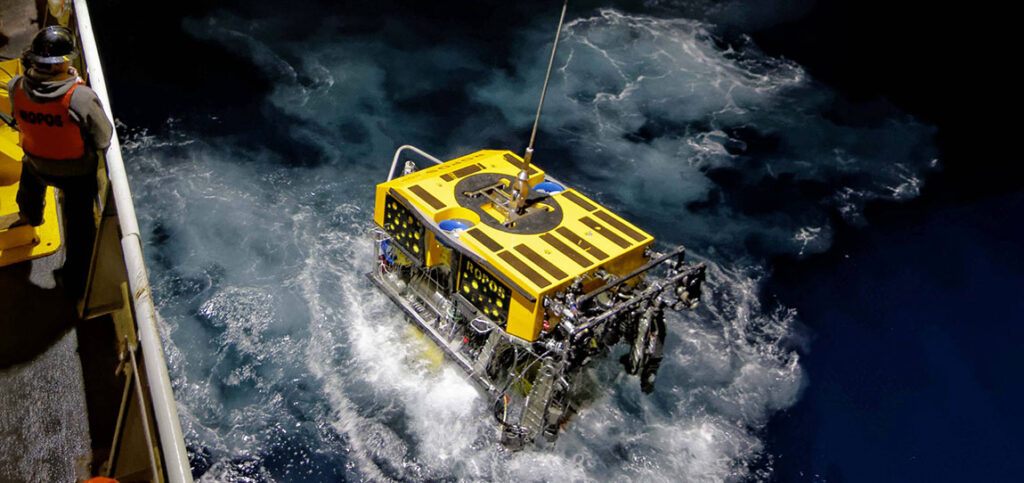

Navigate your marine environment with the confidence only SPRINT-Nav can provide.

Pinpoint location precision. Enhance your operations by adding valuable location detail enabling you to identify exactly where your data is drawn from or to pinpoint the location of assets, obstacles and pipelines.

Guide, control and navigate your USVs, ROVs and AUVs faster, safely and more efficiently with SPRINT-Nav. Operate your vehicles and vessels with the confidence of knowing exactly where they are and what they’re doing.

No calibration needed. Straight out of the box SPRINT-Nav is ready to go, saving you precious time on your operations.

Reduced in size – but not in performance, SPRINT-Nav Mini is the industry’s smallest all-in-one hybrid acoustic-inertial subsea navigator. It provides the perfect instrument for you to control your smaller inspection class ROVs and small to medium sized USVs.

Navigating – to hold station, SPRINT-Nav DP provides a reliable dynamic positioning reference in shallow water for your surface vessel to remain in one place without the need for a GNSS signal.

Engineered for all autonomous vehicles no matter what size or purpose, there is a SPRINT-Nav for your operations.

Why should you invest?

By choosing SPRINT-Nav you are choosing an all-in-one acoustic-inertial navigation sensor, replacing the need for a separate DVL, pressure sensor and INS/AHRS. Saving you the time, cost, cabling and integration challenges associated with using different sensors from different vendors.

At a glance

- Unique to Sonardyne

- Performance levels to suit your operations

- Tightly integrates raw acoustic, Doppler and inertial data

- Titanium housed for deep ROV missions

- Outputs altitude, depth, orientation and velocity

- Configure and control using a Web UI

Compact

Low power and small, it’s the ideal size for installing on all size ROVs as well as USVs undertaking data harvesting missions in shallow water and around offshore structures which often block GNSS signals.

Cost-effective

Because it’s cheaper than the four separate sensors it replaces (AHRS, DVL, INS and pressure sensor), it’s a cost-effective solution for your research platforms where budgets need to stretch as far as possible.

Specialist applications

SPRINT-Nav X is the highest-grade model in our SPRINT-Nav family designed for very specialist applications such as long endurance missions using XLUUVs.

Survey

Supports dual ROV and Survey use and standalone ROV guidance. Also provides mid-water station keeping with vendor independent USBL aiding.

Overview

Its high power output and Wideband 3 signal processing offers improved operating range and acoustic performance in challenging conditions such as when deployed from noisy vessels or in multi-path environments.

The internal Lithium-ion rechargeable battery pack minimises the supply current for long dunker cables. It also enables relocation of the dunker if the cable is cut.

The robust AGP connector on the Dunker 6+ is identical to the ROVNav 6+ and HPT USBL for compatibility and to reduce spares.

At a glance

- Perfect for commanding LBL transponders

- Use it to recover data from Fetch and AMTs

- Capability to operate as topside for RT 6 acoustic releases

- Deploy it over-the-side of your vessel

- Rugged mechanics and connectors

- Shock mounted internal electronics

Dunker 6+ LBL and telemetry transceiver is fully compatible with our modem and sensor logging instruments such as AMT and Fetch , allowing it to be used to retrieve data or configure logging regimes. It can also be used to release the RT 6 range of acoustic releases.

The Dunker 6+ system consists of 100 m of cable on a stainless steel cable drum with brake and locking mechanism. The 10 m deck cable between the 48 V Surface Interface Unit (SIU) and the cable drum allows the drum to be conveniently located. The connection to the cable drum is via an easily replaceable 8-way SubConn.

Optionally, an RT 6 topside kit with 30 m of cable is available in a carrying case without a cable drum.

Specifications table

| Feature | Type 8309-1351 | Type 8309-1353 | Type 8309-1355 | Type 8309-1356 | |

|---|---|---|---|---|---|

| Depth rating | 1,000 m | 1,000 m | 1,000 m | 1,000 m | |

| Operating frequency | MF (20–34 kHz) | MF (20–34 kHz) | LMF (14–19 kHz) | LMF (14–19 kHz) | |

| Transducer beam shape | Omni-directional | Directional | Omni-directional | Directional | |

| Transmit source level (dB re 1 µPa @ 1 m) | 187–196 dB (4 levels) | 190–202 dB (4 levels) | 187–196 dB (4 levels) | 187–202 dB (4 levels) | |

| Tone Equivalent Energy (TEE) | 193–202 dB | 196–208 dB | 193–202 dB | 193–208 dB | |

| Receiver sensitivity (dB re 1 µPa) | 90–120 dB (7 levels) | 80–120 dB (7 levels) | 90–120 dB (7 levels) | 80–120 dB (7 levels) | |

| Range precision | Better than 15 mm | Better than 15 mm | Better than 15 mm | Better than 15 mm | |

| Serial communications (software programmable) |

Primary port: RS485 (half-duplex) or RS232 Secondary port: RS485 (half-duplex) or RS232 or SYNC IN |

Primary port: RS485 (half-duplex) or RS232 Secondary port: RS485 (half-duplex) or RS232 or SYNC IN |

Primary port: RS485 (half-duplex) or RS232 Secondary port: RS485 (half-duplex) or RS232 or SYNC IN |

Primary port: RS485 (half-duplex) or RS232 Secondary port: RS485 (half-duplex) or RS232 or SYNC IN |

|

| Operating voltage | 24 or 48 V dc (±10%) | 24 or 48 V dc (±10%) | 24 or 48 V dc (±10%) | 24 or 48 V dc (±10%) | |

| External power | Active (listening) | <3 W typical (max 6 W when charging) | <3 W typical (max 6 W when charging) | <3 W typical (max 6 W when charging) | <3 W typical (max 6 W when charging) |

| Peak (during transmission | <80 W | <80 W | <80 W | <80 W | |

| Battery life Li-ion (listening) | 3 days | 3 days | 3 days | 3 days | |

| Connector type | AGP (8-way female) | AGP (8-way female) | AGP (8-way female) | AGP (8-way female) | |

| Mechanical construction | Super-duplex stainless steel | Super-duplex stainless steel | Super-duplex stainless steel | Super-duplex stainless steel | |

| Dimensions (length x diameter) | 692 x 200 mm | 660 x 200 mm | 586 x 200 mm | 641 x 230 mm | |

| Weight in air/water | 24/16 kg | 26/17 kg | 20/14 kg | 28/17 kg | |

| System kit | |||||

| Dunker 6, SIU, 100 m cable drum etc. | 602-0047 | 602-0053 | n/a | 602-0072 |

Frequently asked questions

STP files

Software and firmware

Software and control hardware

Datasheets

Manuals and quick start guides

Did you know?

Dunker 6+ can be used to recover data from Fetch and AMTs

Overview

The ESH is the network interface between the in-water acoustic instrument, GPS and the PC that runs the positioning software.

In addition to accurately time-stamping incoming data from external devices such as gyro, VRU and GPS it provides power and communications for acoustic transceivers.

The ESH includes a time source that can be linked to an internal or external GPS PPS input, allowing the Ranger 2 system to accurately time-stamp incoming data from external devices such as gyro, VRU and GNSS to UTC.

Wi-Fi connectivity allows connection to a PC using a Wi-Fi adapter.

At a glance

- Topside control unit for Mini-Ranger 2 USBL installations

- Provides power and comms to HPT 2000/3000 transceiver

- Integral GNSS with SBAS

- 4 serial ports RS232

- Wi-Fi connectivity

Specifications table

| Feature | Type 8211 |

|---|---|

| Storage | Internal 32 GB eMMC |

| Ports and Connectors | 4 x RS232 ports (DB 9) |

| 3 x RJ45 10/100 Ethernet sockets | |

| 1 x BNC jack 1PPS input | |

| 1 x BNC jack responder output 12 V, 100 mA | |

| 1 x SMA jack GNSS input (RF coaxial) | |

| 1 x Reversed polarity-SMA jack (Wi-Fi) | |

| 1 x 48 V transceiver connector (Amphenol) | |

| 1 x IEC socket 115/230 V ac, 1 A, 60/50 Hz | |

| Power Supply | Auto-sensing ac input voltage: 115–230 V, 60/50 Hz |

| Maximum current: 1 A | |

| Average operating current: 0.16 A @ 230 V (without transceiver) | |

| Environmental Specifications | Operating -5 to 40°C (23 to 104°F) |

| Storage -20 to 55°C (-4 to 131°F) | |

| Relative humidity 20–80% (non-condensing) | |

| Vibration – Frequency 5 to 13.2 Hz – 1.0 mm peak displacement | |

| Vibration – Frequency 13.2 to 100 Hz – 0.7 g acceleration | |

| Vibration – DNVGL-CG-0339 class A | |

| Safety | Complies with EN61010-1 |

| EMC | Complies with immunity & emission requirements of EN60945 |

| Dimensions (Length x Width x Height) 1U Rack Mounting (without feet) |

430 x 295 x 44.4 mm (16.9 x 11.6 x 1.75”) |

| Weight | 3.3 kg (7.3 lbs) |

Datasheets

Manuals and quick start guides

Did you know?

ESH can be used as a topside control unit for Mini-Ranger 2 installations

Overview

HPT 2000 offers significant advantages for survey operations in coastal and near shore regions where simultaneous positioning of transponders attached to transition zone/ocean bottom seismic cables at high elevation tracking is required in low noise environments.

The advanced multi-element processing enables transponders to be positioned more precisely, more quickly and more robustly due to improvements in signal processing algorithms. When used as part of a complete Mini-Ranger 2 USBL system, heading and inertial navigation sensor, class leading performance is achieved.

At a glance

- Use it with Mini-Ranger 2 USBL

- Optimised for high elevation tracking in shallow water

- Easy to deploy on temporary over-the-side set up

- Ethernet comms for fast position updates

- Excellent corrosion resistance

The integral MTi-30 Xsens sensor provides pitch, roll and heading data that automatically compensates for the dynamic motion of the vessel, removing the need for an external sensor and pre-use calibration.

Manufactured in Aluminium Bronze, HPT 2000 is intended to be fitted temporarily or permanently to a vessel’s through-hull or over-the-side pole.

The full hemispherical coverage optimises performance in shallow water environments boosting transmissions and receive sensitivity in the horizontal axis.

Ethernet connectivity enables the system to function over existing ship network wiring for rapid installation.

Discover more from our case studies

A new world of multi-robot ocean exploration

Read moreMini-Ranger 2 for the next-level USV operations

Read moreL3Harris takes USBL-aided AUV navigation to the next level

Read moreSpecifications table

| Feature | Type 8221 | |

|---|---|---|

| Operational frequency | HF (33–50 kHz) | |

| Transceiver performance | Operating range | 500 m |

| Acoustic coverage | Full 180° | |

| Range precision | Better than 15 mm | |

| Positioning repeatability external MRU | All transceivers tested to better than 0.2% of slant range 1 Drms / 0.14% 1 Sigma | |

| Positioning repeatability internal Xsens pitch and roll | All transceivers tested to better than 1.3% of slant range 1 Drms / 0.9% 1 Sigma | |

| source level (dB re 1 µPa @ 1 m) | 194 dB | |

| Electrical | 48 V dc (±10%), typical 15 W, maximum 120 W | |

| Communication | Ethernet 100 Mbps | |

| Operating temperature | -5 to 40°C | |

| Storage temperature | -20 to 45°C | |

| Mechanical construction | Aluminium bronze | |

| Dimensions (height x diameter) | 310 x 234 mm | |

| Weight in air/water | 19.4/9.5 kg | |

| Note: The absolute accuracy of the system is dependent upon the quality of external attitude and heading sensors, beacon source level, vessel noise, water depth, mechanical rigidity of the transceiver deployment machine, SV knowledge and proper calibration of the total system using CASIUS. |

Frequently asked questions

How to clean a transceiver array face

HF Beacon Positioning for Transition Zone and Ocean Bottom Cable Applications

HPT 2000/3000 Testing

Has anyone ever installed an echosounder and Ranger 2 USBL transceiver directly beside each other? Would this work?

Does the HPT’s main connector need any maintenance?

STP files

Software and firmware

Software and control hardware

Datasheets

Manuals and quick start guides

Did you know?

HPT 2000 can be used as part of our Mini-Ranger 2 USBL system

Overview

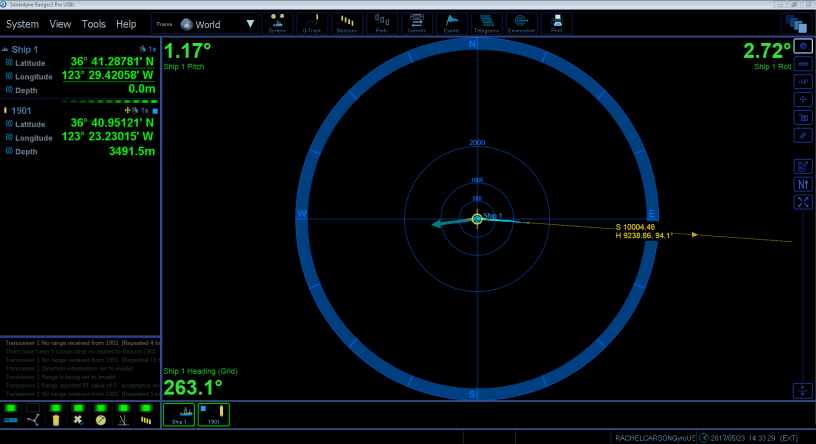

When it comes to USBL and LUSBL transceivers, one model does not fit all situations and vessels. For Ranger 2 and Marksman installations, our High Performance Transceiver (HPT) is available two primary configurations.

HPT 5000

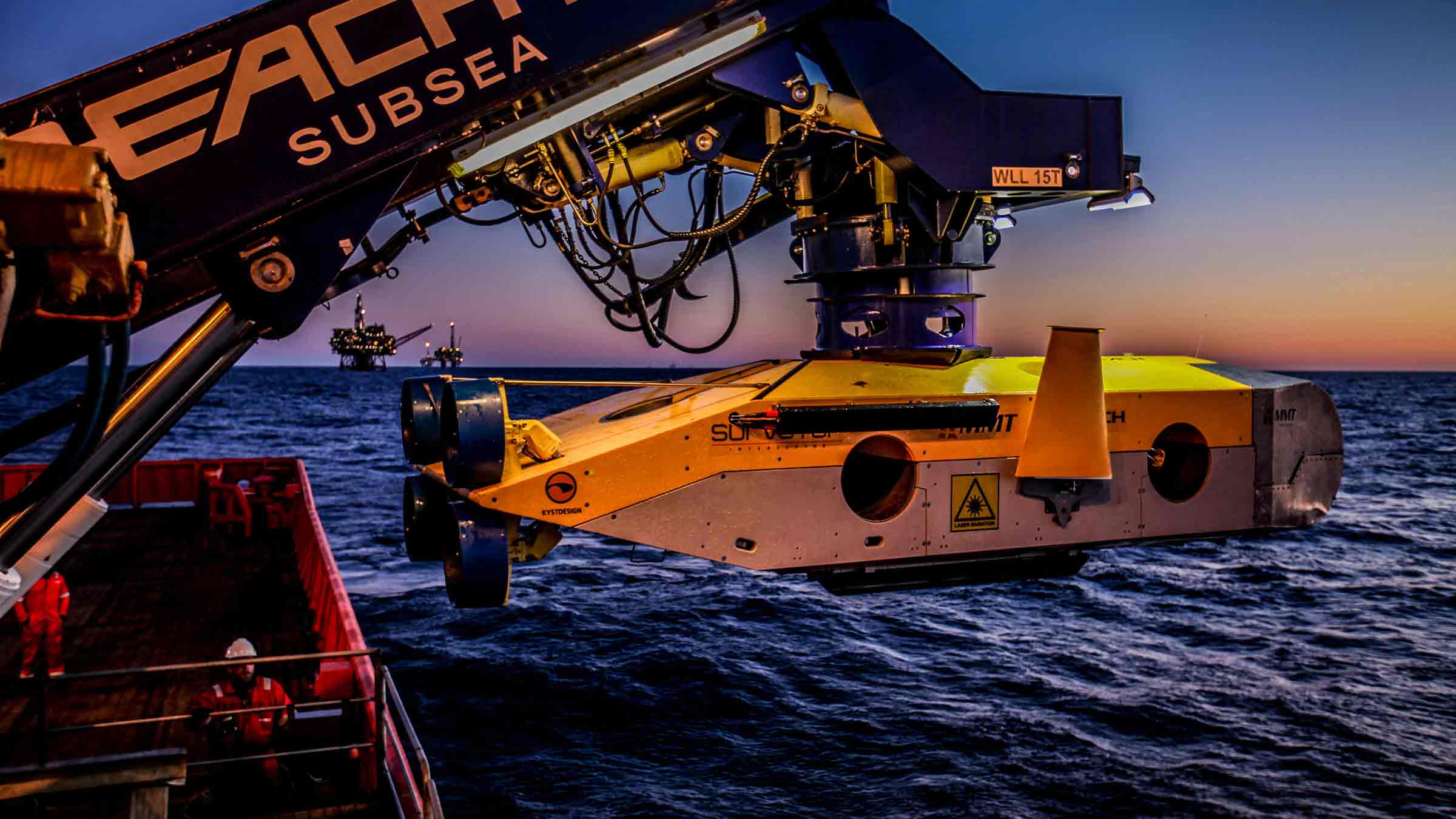

HPT 5000 offers full hemispherical acoustic coverage so it’s a popular choice for tracking multiple targets (ROVs, AUVs, towfish, seafloor sensors) over a wide range of depths and elevations. The unit is also suitable for dynamic positioning reference on survey, research and offshore support vessels.

HPT 7000

HPT 7000 is engineered for ultra-deepwater operations, tracking targets far below (rather than to the side) of a vessel, and also high vessel noise operating environments, as those typically encountered on DP drilling and construction where aeration from thrusters is liable to cause signal interference.

Both models of transceiver fully support 6G LBL operations using Fusion 2 LBL software. They are also highly capable acoustic communications modems, able to interrogate, command and recover data payloads from deployed Sonardyne instruments including AMTs and Fetch. Supporting telemetry rates of up to 9,000 bps minimises the time a vessel has to wait on location to recover data, as well as supporting LBL operations.

HPT 5000/7000s are also available in Gyro USBL configurations offering calibration-free installation and use.

At a glance

- Use with Ranger 2 USBL and Marksman LUSBL systems

- Can also be used to communicate and harvest data from Sonardyne sensors

- Hemispherical (HPT 5000) or directional (HPT 7000) arrays to suit your vessel and application

- Can be deployed other-the-side, through-tube or through-hull

- Suitable for new-build vessels or USBL/LUBL upgrade for your existing vessel

All HPTs are built on our 6G technology platform with multi-element processing to enable transponders to be positioned more precisely, more quickly and more robustly due to improvements in signal processing algorithms and array design.

Functionality such as ‘Discovery Mode’ enables vessels equipped with Ranger 2 and Marksman to enter an offshore area and automatically detect previously deployed transponders (including their configured address and channel), making simultaneous operations using shared seabed arrays possible.

Manufactured in aluminium-bronze, HPTs are intended to be fitted temporarily or permanently to a vessel’s through-hull or over-the-side pole. HPT 5000s (including Gyro USBL 5000s) have also been fitted to large USVs for uncrewed missions controlled from over-the-horizon.

For specialist applications, inverted USBL, LMF frequency and extreme depth range HPT transceivers are also available. Please get in contact to discuss your requirements.

Ranger 2 in action

Optimising shallow water positioning for combined magnetometer and hydrographic surveys

Read moreAutonomous robots prepare to storm the ocean depths

Autonomous robots prepare to storm the ocean depths

A new world of multi-robot ocean exploration

Read moreSpecifications table

level, vessel noise, water depth, mechanical rigidity of the transceiver deployment machine, SV knowledge and proper calibration of

the total system using CASIUS.

| Feature | Type 8142-001 | Type 8142-002 (deepwater optimised unit) | |

|---|---|---|---|

| Operational frequency | MF (20–34 kHz) | MF (20–34 kHz) | |

| Transceiver performance |

Operating range | Up to 7,000 m | Up to 7,000 m |

| Acoustic coverage | Up to ± 90° | Up to ± 90º Optimised for deep water (depending on frequency of operation) |

|

| Range precision | Better than 15 mm | Better than 15 mm | |

| Positioning repeatability | All transceivers tested to better than 0.1% of slant range 1 Drms | All transceivers tested to better than 0.07% of slant range 1 Drms | |

| Transmit source level (dB re 1 µPa @ 1 m) | 200 dB | 200 dB | |

| Tone Equivalent Energy (TEE) | 206 dB (13 JA) | 206 dB (13 JA) | |

| Electrical | 48 V dc (±10%), Typical 15 W, Max 120 W |

48 V dc (±10%), Typical 15 W, Max 120 W |

|

| Communication | RS485, baud rate switchable, ethernet 100 Mbps |

RS485, baud rate switchable, ethernet 100 Mbps |

|

| Operating temperature | -5 to 40°C | -5 to 40°C | |

| Storage temperature | -20 to 45°C | -20 to 45°C | |

| Mechanical construction | Aluminium bronze | Aluminium bronze | |

| Dimensions (length x diameter) | 322 x 225 mm | 391 x 310 mm | |

| Weight in air/water | 26.7/15.3 kg | 46.9/29.0 kg | |

| Options | Tilted array adaptor | Tilted array adaptor |

Frequently asked questions

How to clean a transceiver array face

How to enter Transceiver & Lodestar Offsets for Optimised USBL

HPT Deployment Tests

Has anyone ever installed an echosounder and Ranger 2 USBL transceiver directly beside each other? Would this work?

How do USBLs work?

Does the HPT’s main connector need any maintenance?

When to use Depth Aiding

What acoustic address should I use for my USBL transponder

How to interface Ranger 2 into a 3rd party survey system

STP files

Software and firmware

Software and control hardware

Datasheets

Did you know?

Both HPT 5000 and 7000 are available in Gyro USBL configurations

Overview

Using a superfast processor to handle intensive workloads, Marine Computer is designed and configured to provide you with the best possible experience when using our suite of navigation, positioning and imaging software products, leaving you to concentrate on the job in hand.

However, you don’t have to be using Sonardyne software to use one. If you’re in the market for a robust and easily configured computer to run third-party software applications onboard your ship, survey boat or unmanned craft, Marine Computer is the perfect choice.

That’s because it’s certified to EN60945 and DNVGL-CG-0339 standards which means it meets regulatory requirements to be used on ships’ bridges and is able to withstand harsh operating environments and where constant high temperatures are present.

At a glance

- Choice of desktop or 2U rack mount configurations

- Fanless and temperature tolerant design withstands harsh marine operating environments

- Certified to EN 60945 and DNVGL-CG-0339 – use it on your bridge

- Intel 8th generation CPU runs intensive applications with ease

- Desk, console and rack mounting options

- Wide operating temperature range

Fanless computers like the Marine Computer are perfect for use in dirty or dusty marine environments where actively cooled systems could quickly clog up, overheat and fail. Inside is an Intel 8th generation processor and 512 GB industrial grade solid state disk. SSDs have no moving parts so are faster and more reliable than traditional hard disk drives. Temperature tolerant components contribute to its impressive wide operating temperature range.

All this makes the Marine Computer an extremely versatile and reliable tool in virtually any marine installation condition: desk mounted, in a small survey boat; within a ship’s bridge console; or, when supplied with a custom 2U chassis, mounted in a server room rack.

Watch our youtube video to learn more

Specifications table

| Feature | Specification | |

|---|---|---|

| Processor | Intel i7 8700T Hexacore 2.4 GHz | |

| RAM | 8 GB 2666 MHz DDR4 RAM (non-ECC, un-buffered) |

|

| Hard drive | Single 512 GB industrial grade SSD | |

| Drives | Additional 2.5” SATA drive bay | |

| Ports | 1x DVI, 2 x DisplayPort 1.2, 2x USB 3.1 Gen2, 4x USB 3.0, 2x USB 2.0, 4 x RS232/422/485 serial ports (with auto flow control), 1x PS2 port, 1x Line in, 1x Mic in, 1x Phone jack 3.5mm, External Fan port, external power port, external reset port |

|

| Network | 2x 1 Gbps Ethernet | |

| Power in | Auto sensing ac voltage: 115/230 V, 60/50 Hz Max power input: 221 W Input current: 2 A @ 230 V |

|

| Audio | Realtek® ALC888 high definition audio | |

| Video | Supports triple independent display | |

| Environmental specifications | Operating temperature, storage temperature, relative humidity Vibration Shock |

-15 to 70ºC (5 to 158°F) -15 to 70ºC (5 to 158°F) 95% @ 70°C (non-condensing) 5 Grms, 5–500 Hz, 3 axes according to IEC60068-2-64 50 Grms, half-sine 11 ms duration according to IEC60068-2-27 |

| Intended use | Indoor use (including bridge), altitude up to 2,000 m, continuous operation | |

| EMC | Immunity & Emission EN 60945 & DNVGL-CG-0339 compliant |

|

| Dimensions (WxDxH) | Unmounted | 227 x 261 x 88 mm (8.9 x 10.3 x 3.5”) |

| Shelf mounted | 482 x 423 x 88 mm (19.0 x 16.7 x 3.5”) | |

| Weight | Unmounted | 4.3 kg |

| Shelf mounted | 10.5 kg | |

| Options | 265-5831 | 512 GB SSD |

| 650-0219 | Connector pack (1x dc power terminator, 1x SW reset terminator, 1x reset terminator, 1x fan terminator) |

Frequently asked questions

Datasheets

Manuals and quick start guides

Technical bulletin

Overview

NSH is a 2U high rack-mounted unit that is the interface between your in-water deployed transponders, vessel-mounted transceiver and Marine Computer which runs Ranger 2 USBL or Marksman LUSBL software applications.

In addition to accurately time-stamping incoming data from external devices such as gyro, VRU and GNSS, the NSH also provides power and communications for ship-borne acoustic transceivers such as HPT 5000 or HPT 7000.

A range of hardware interface cards are available for interfacing Sonardyne transceivers and external sensors. By simply plugging these cards into the rear of the unit, the role of the Navigation Sensor Hub can be transformed from supporting simple to complex acoustic operations.

The NSH includes an IEEE-1588/PTP precision time source that can be linked to GPS PPS input. Multiple NSHs automatically synchronise their clocks. All incoming data is time stamped to sub-microsecond accuracy – outgoing transmissions and triggers can be scheduled to the same precision.

Depending on the application (DP, drilling or survey operations), the NSH can be configured in stand-alone, dual-independent or dual-redundant modes.

At a glance

- Use it with Ranger 2 and Marksman LUSBL systems

- Interfaces vessel’s acoustic instruments with operating software

- Time stamps gyro, VRU and GNSS data

- Offers up to 16 serial ports (RS232/485)

- Configurable for dual independent applications

Specifications

| Feature | Type 8098 | |

|---|---|---|

| Processor | Freescale PowerQUICC™ II Pro Processor running at 1000 MIPS | |

| Memory | One single SO-CDIMM DDR2 PC4200 512MB Module | |

| Motherboard | Proprietary Sonardyne Type 8098-046 | |

| Ports and Connectors | AC IEC power connector socket | |

| 12 x Interface card connectors | ||

| Power Supply | Auto sensing ac input voltage: 100-240 V, 50/60 Hz | |

| Max current: 2 A @ 240 V, 4 A @ 110 V | ||

| Ave. operating current: 0.32 A @ 240 V | ||

| Environmental Specifications | Operating | -5 to 40°C (23 to 104°F) |

| Storage | -20 to 55°C (-4 to 131° F) | |

| Relative Humidity | 20–80% (non-condensing) | |

| Shock | 10 G acceleration peak to peak | |

| 5–17 Hz, 0.1” double amplitude displacement | ||

| 17–640 Hz, 1.5 G acceleration peak to peak | ||

| Safety | Complies with EN61010-1 | |

| EMC | Complies with Immunity & Emission requirements of EN60945 | |

| Dimensions (Length x Width x Height) | 384 x 482 x 88 mm (15.1 x 18.9 x 3.4”) |

Frequently asked questions

Software and firmware

Software and control hardware

Datasheets

Manuals and quick start guides

Did you know?

NSH can be used with Ranger 2 and Marksman LUSBL systems