As an engineering company, we like numbers – very precise numbers in fact. While those numbers normally relate to water depth, range, frequency or days of vessel time saved using our equipment, etc., we’re currently getting to grips with some new numbers relating to our energy use and carbon footprint.

At the beginning of this year, we had 1,316 solar panels installed by Clean Earth Energy across the three buildings that make up our UK headquarter campus; Ocean House, Fathom House and Haven House. Each unit measures 201.5 cm × 99.6 cm, so in total they cover 2,641 m² (or just under 13 tennis courts). They’re the latest, most efficient panels and inverters on the market; JA Solar 405W high-efficiency PERC half-cell modules and SolarEdge inverters, respectively, which unlike earlier generation panels, allow us to individually monitor every panel for efficiency and performance.

A solar powerhouse – or rather three powerhouses

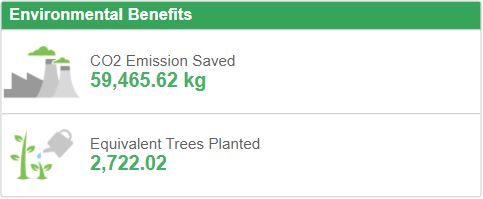

Together, our rooftop solar farm amounts to 533 kW that will generate in our part of southern England around 470,000 kWh per year. We estimate this will cover a minimum of a third of the energy consumption across our three buildings. That’s an annual 120 tonnes of CO2 equivalent emissions (CO2e) we have prevented from being emitted, not to mention the clean energy going back into the national grid when we’re not consuming it. It’s a great investment and one which has been several years in the making.

But while we’re hugely pleased to have these panels up and running, solar power generation is just the latest energy saving initiative we’ve committed to. In 2018, we invested in a Building Management System (BMS), which has learning algorithms to make the most efficient use of energy. It looks at how the building is heating and cooling to maximize efficiency, using things like destratification fans to move heat in a large space. We also changed all our light bulbs to LED panels and upgraded our heating systems to the most efficient types, including adding heat pumps. The result was that, between 2015-2019, energy consumption across our Blackbushe site was reduced by 23.5%. We’ve also reduced our travel overheads (even prior to Covid-related restrictions). What’s more, the electricity we are buying is all renewable, under a 100% renewable electricity supply we have, and now, thanks to the solar arrays, we’re putting more renewable power into the grid under Ofgem’s Renewable Energy Guarantees of Origin (REGO) scheme.

Calculating CO2e savings

Needless to say, for the past few years we’ve been formally calculating our carbon footprint, using the government approved PAS 2060 Specification, which has shown that, between 2018-2019, we reduced our emissions from 1,047 to 737 tonnes. With the solar panels coming online this year, we’ll see another dramatic drop in our 2019-2020 numbers.

All of these initiatives tie into our ISO 50001 Energy Management System Standard certification, which provides a framework of requirements relating to more efficient use of energy and continued improvement of energy management, so our efforts certainly do not and will not end here. We’re already looking at what more we can do. We’re also compliant with Energy Saving Opportunity Scheme (ESOS) Regulations and the Streamlined Energy and Carbon Reporting scheme.

Reduced waste as well as energy consumption

Of course, our impact on the environment doesn’t end there. We have also been focusing on reducing our waste streams across our sites globally, diverting more to recycling and doing more on a paperless basis. This has resulted in the removal of many tonnes of paper from our archives over the past 11 months, all of which has been recycled responsibly by a specialist. Our product design and manufacture through to recycling also follow European directives such as the Restriction of Hazardous Substances (RoHS) and Waste Electrical and Electronic Equipment (WEEE), using quality, sustainably sourced recyclable components.

There’s more to come, but if you’re interested in what we’ve done to date, feel free to get in touch.