Dynamic laser scanning

Overview

Dynamic and fast

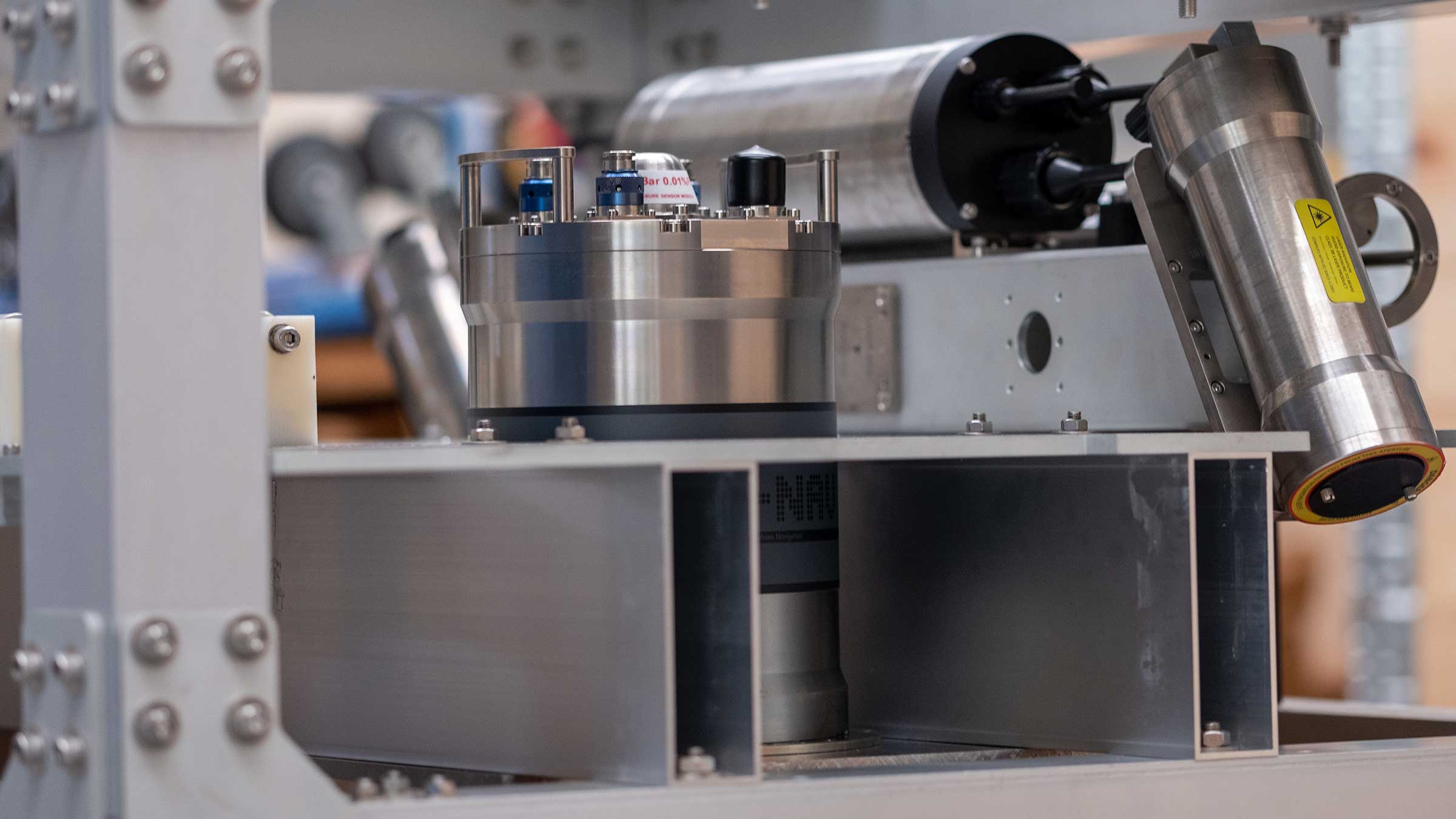

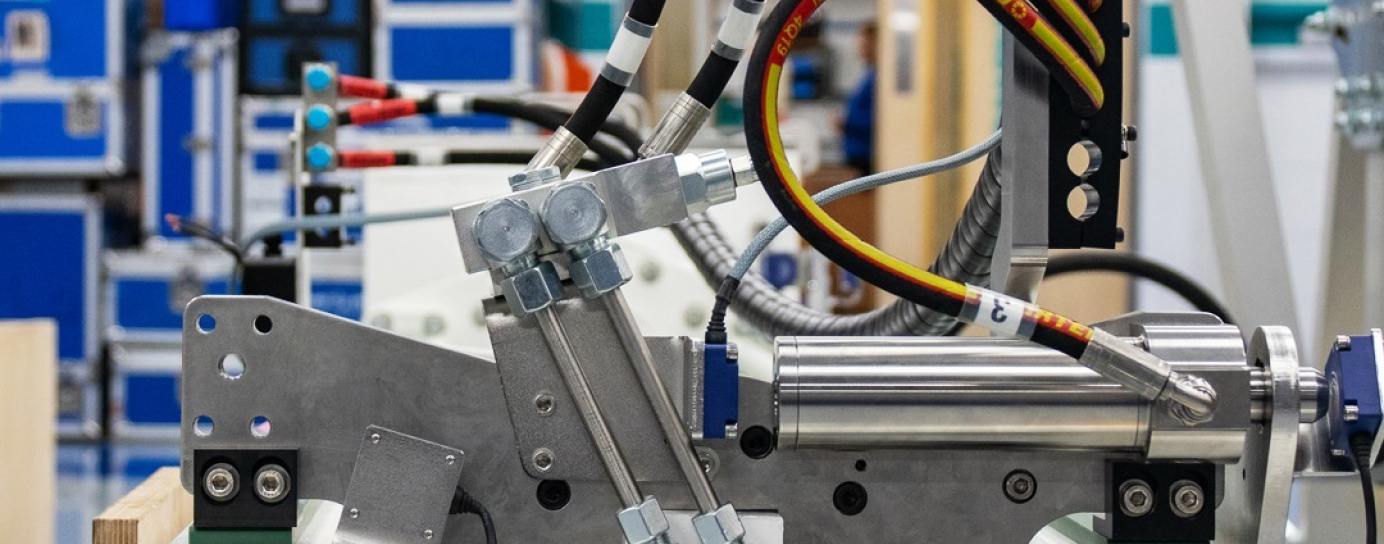

Our dynamic laser scanning skid is a turn-key survey solution comprising of all the hardware and software, pre-configured and calibrated, to enable simple and fast mobilisation, efficient acquisition, and if needed, in-person or remote support from our expert surveyors.

The skid is fitted with a SPRINT-Nav, ROVNav 6+, sound velocity, conductivity and temperature sensors, and a custom Voyis ULS500 Pro.

All the sensors are interfaced via an Innova Titan Matrix MKII+ multiplexor.

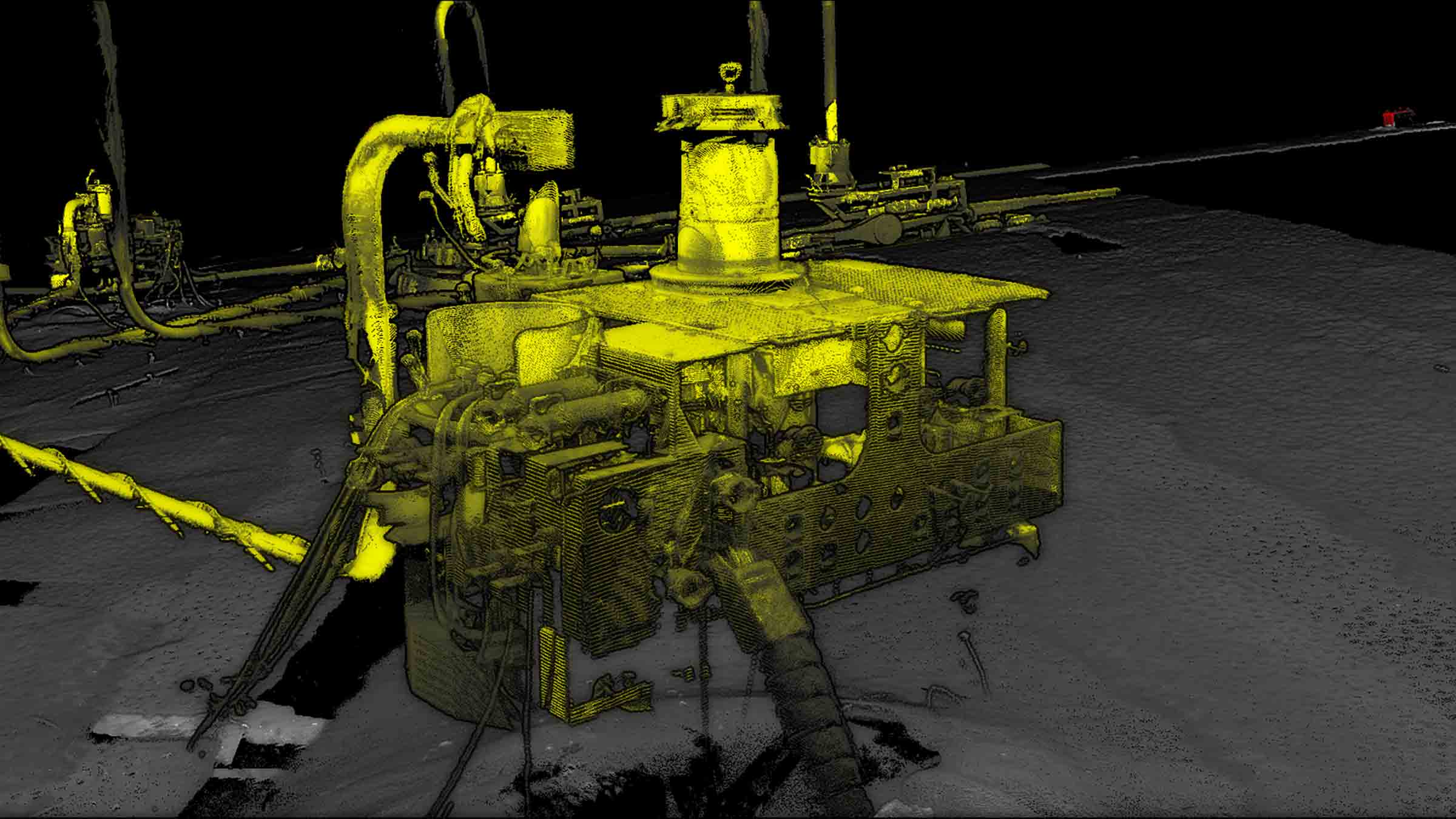

Until now, because dynamic centimetric-level navigation with fast update rates has not been commercially available, subsea laser and LiDAR systems have predominantly been used in a static mode. Due to the relatively short ranges achievable from these systems, multiple scans are required involving relocating the system to a number of locations on the seabed. Operationally, this is time consuming, both in terms of physically relocating the scanner, waiting for the visibility to clear after the scanner has been placed on seabed, and then processing time to merge the data together. It also means scans are limited to side, ground-level views.

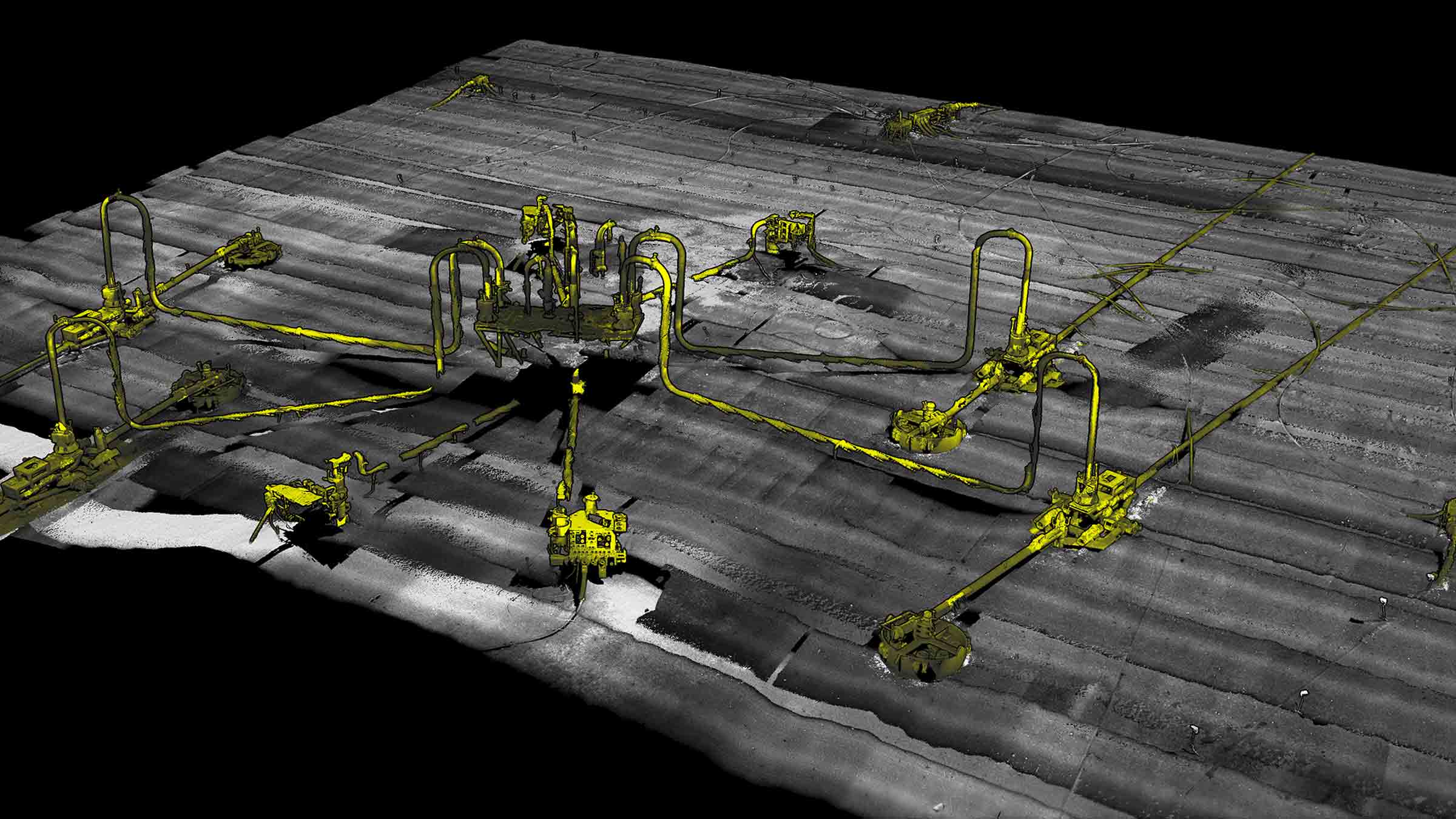

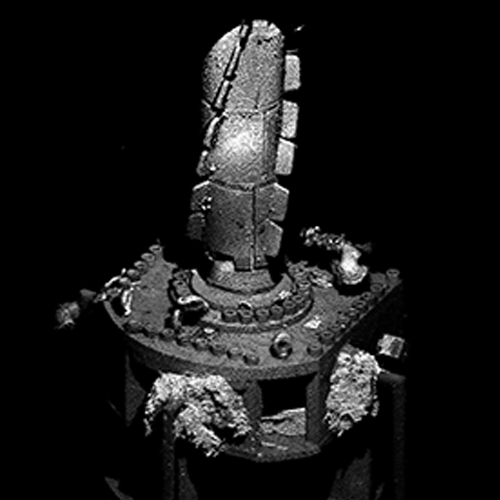

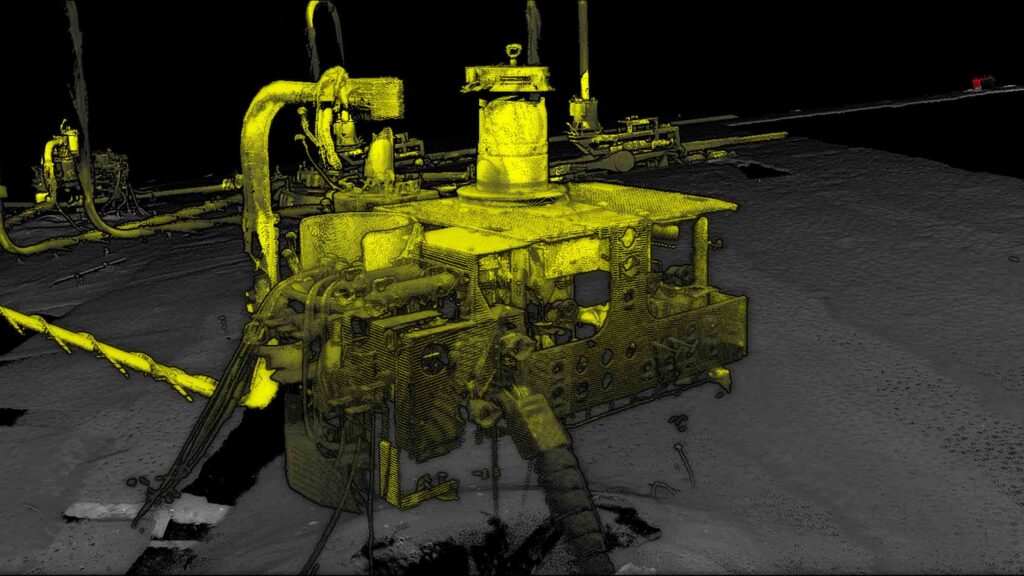

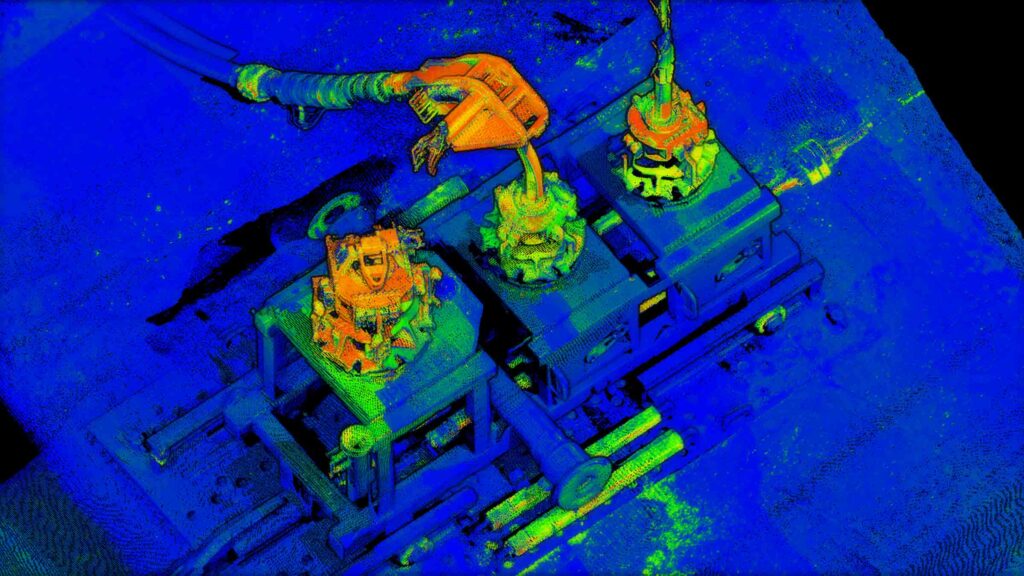

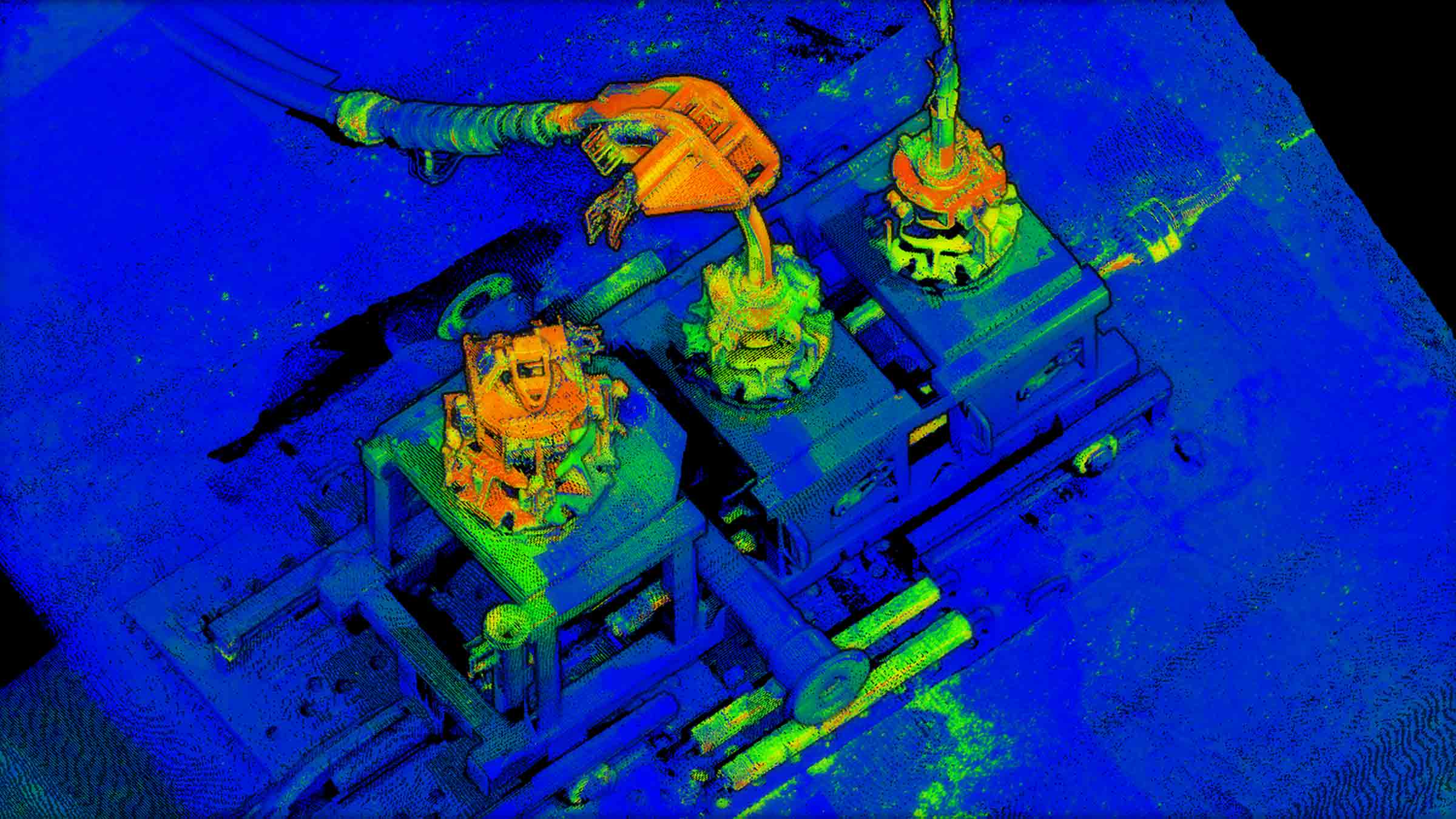

With our dynamic platform, a site can be mapped quickly with no issues of reduced visibility as the ROV does not come into contact with the seabed and can move to scan any target of interest – including from above. High resolution point cloud data can contain a wealth of information which can be utilised for various engineering requirements, including revealing previously unknown features.

At a glance

- Fully DNV certified

- Rated to 4000 m

- De-risk your surveys: all sensors are interfaced and ready to go

- Sensors are pre-calibrated saving valuable offshore time

- Designed for Workclass ROVs

- Simple plug-and-play interfacing only requires power and fibre communication with ROV

All-in-one service

-

A tightly integrated, acoustically-aided navigation solution capable of meeting any positioning specification

-

Integration with other Sonardyne Group companies, Voyis and EIVA, enable the full package to be provided and supported

-

Help with planning your operations via our Survey Support Group

-

We are able to provide experienced surveyors to assist with operations, either offshore or remotely via our ROAM service

-

Navigation post processing service available

Technology differentiators

-

We aid SPRINT-Nav with tightly coupled two-way acoustic travel times, with each range received individually and precisely time-stamped

-

We combine individual Syrinx DVL beam velocities within SPRINT-Nav rather than generic DVL XYZ velocity

-

All acoustic aiding (LBL and DVL) uses rich proprietary quality metrics, and timing is guaranteed to the micro-second level

-

SPRINT-Nav INS provides direct time synchronisation (1PPS) for the ULS500 Pro, removing risk of issues with latency or timing jitter on ROV MUX communications to topside

-

Our Janus software is an extremely powerful tool for ensuring the very highest quality post-processed navigation with full QC of data. It performs both forwards and backwards post-processing of the INS data.

-

Logging of relative tidal data from a Compatt 6+ that can be used in post processing

Energy

Dynamic laser scanning enables large offshore sites to be mapped quickly and with complete precision, meaning complex structures and drill centres can now be scanned whilst minimising vessel time.

Science

With our skid attached to your deep water research ROV, large areas can be mapped in high resolution, including entire wrecks and flora and fauna for habitat classification and population surveys.

Save time during data acquisition

• Comprehensively scan large areas with no gaps in coverage

• Cut survey time: no need to relocate sensor and wait for visibility

• Can operate in reduced turbidity due to being on a dynamic platform

• Scan items of interest at shorter range, in higher density without the need for relocating equipment

De-risk operations

• Backed by our global customer and survey support group network

• Our laser skid is DNV rated for commercial, work-class ROV operations

• All equipment is supplied with the latest software and firmware, meaning no compatibility issues

• The factory-supplied equipment is pre-configured to ensure it can be mobilised as quickly as possible while reducing risks and complexity commonly associated with sensor integrations from several different vendors