Overview

Test against your industry standards

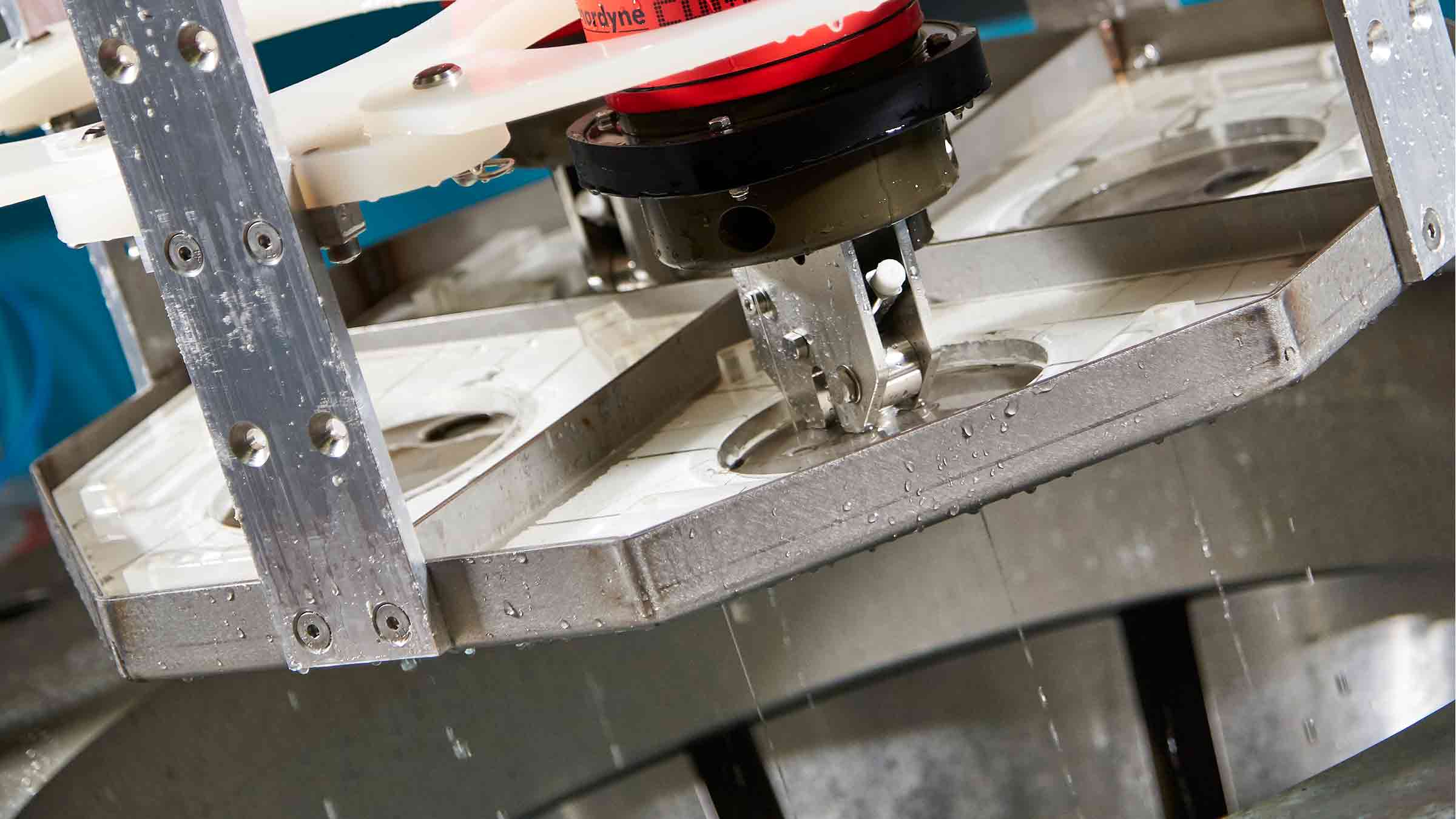

With an internal diameter of 0.76 m and an internal height of 2 m, the chamber can accommodate large single instruments or multiples of smaller instruments at the same time. Equipment under test can be interfaced via six breakout ports which can be adapted to suit client specific connectors, allowing full communications with the equipment whilst under pressure. The chamber is filled with tap water mixed with a corrosion inhibitor.

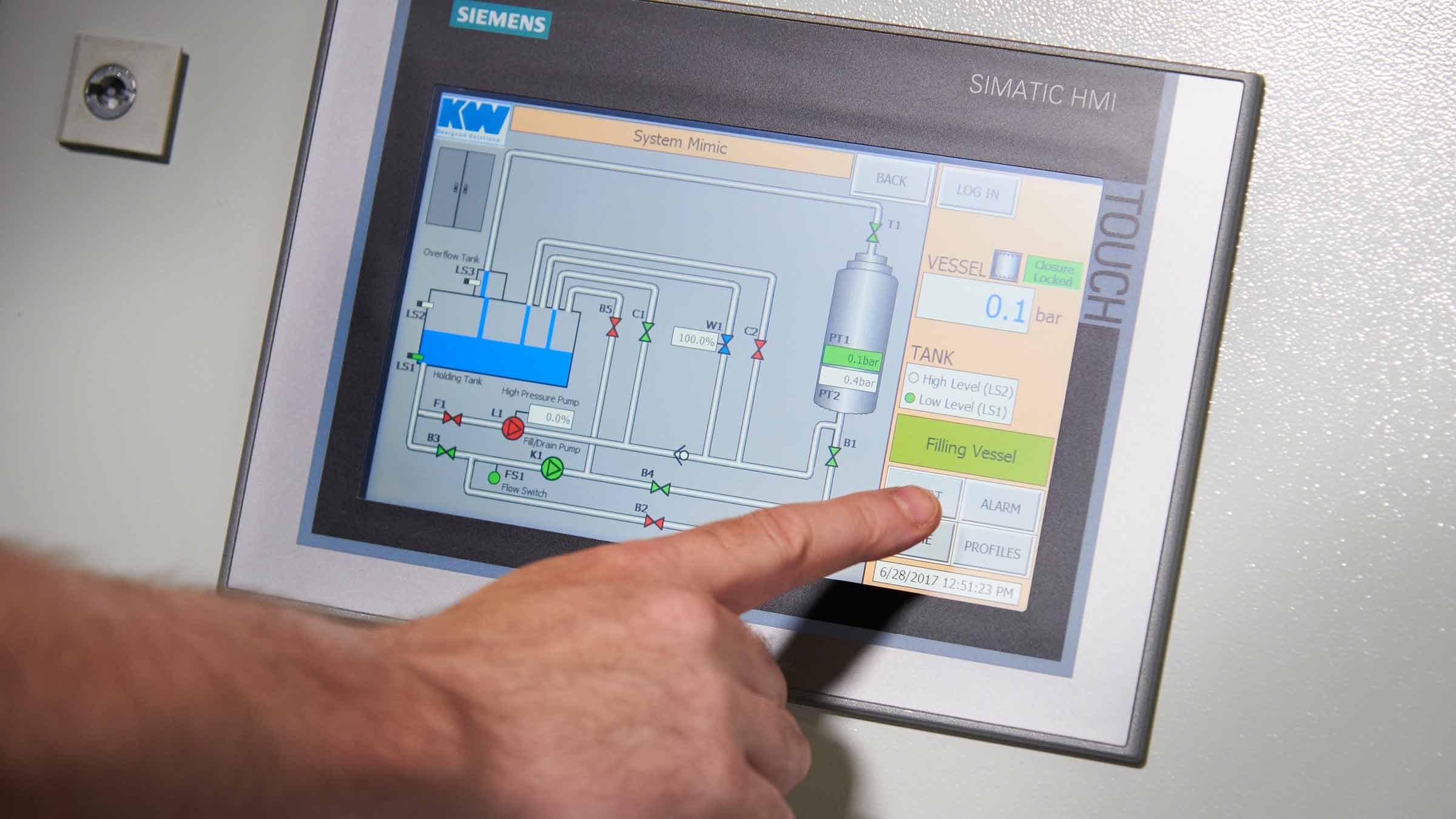

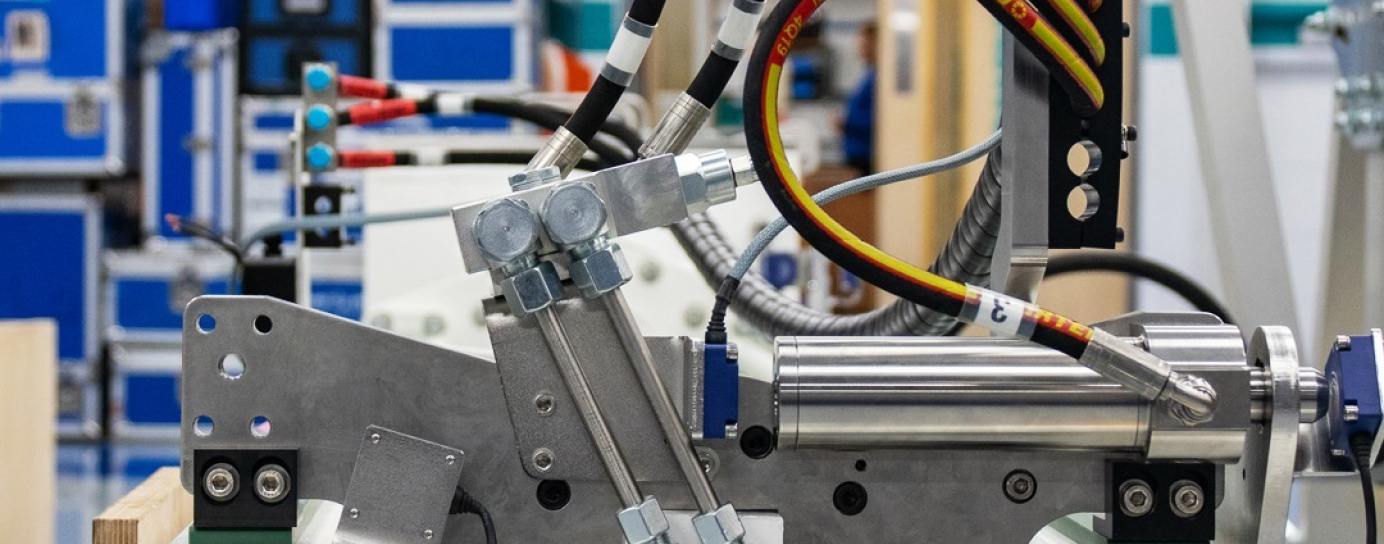

The control system for the chamber can be programmed to meet the requirements of specific industry standards including pressure cycling, ramping and holding. Ramp rates of up to 50 bar/min can be programmed and pressure inside the chamber logged. A dedicated engineer supervises all testing activities and can provide you with a full report which includes applied pressure graphs, test certificates and photographic records.

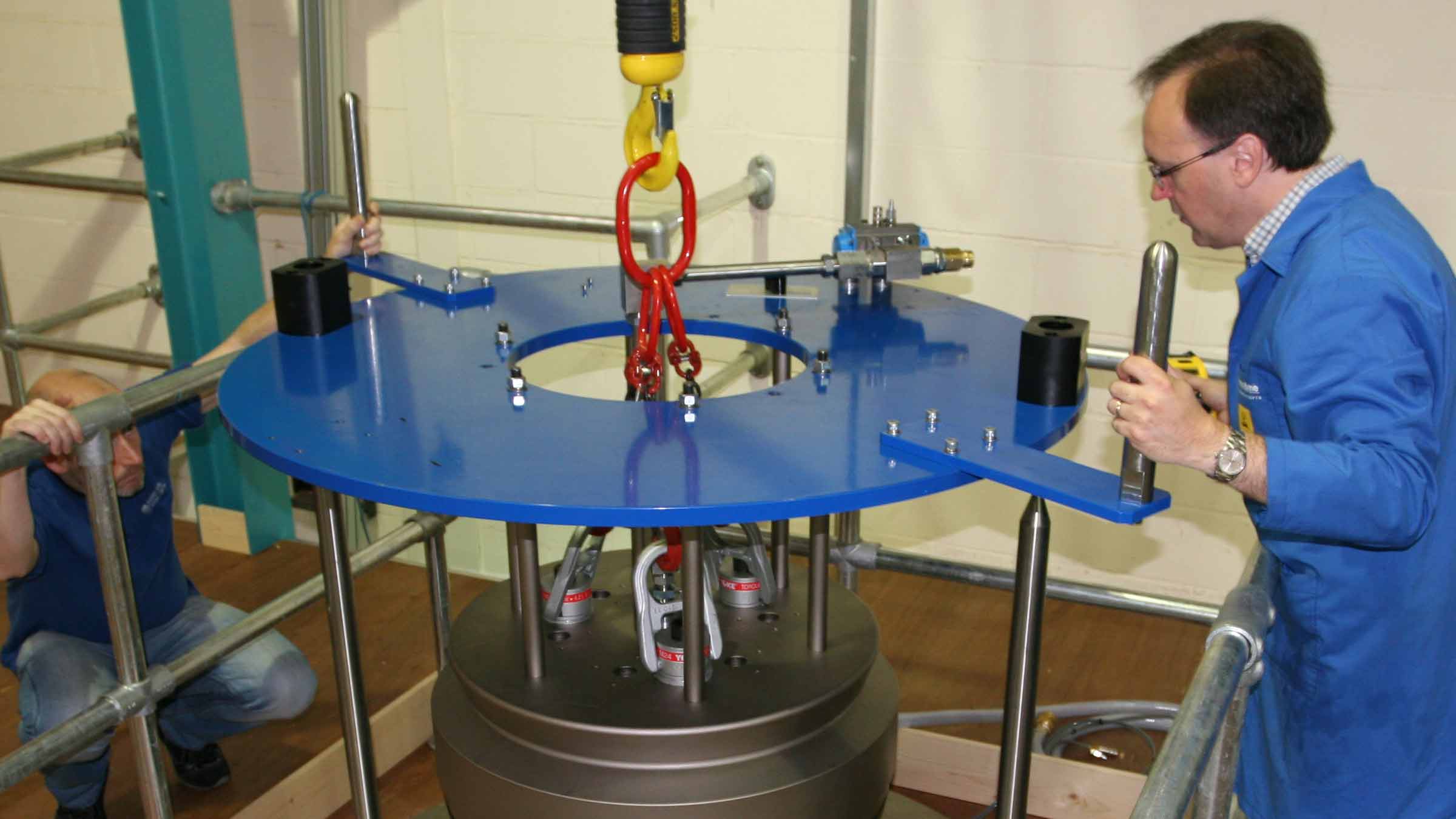

Equipment can be easily unloaded by forklift and manoeuvred into position by a motorised, remotely controlled overhead crane rated to 2.5 tonnes. Guest Wi-Fi access is available, along with technical advice from Sonardyne’s highly experienced electro-mechanical design engineers if required.