Precision depth monitoring for offshore operations

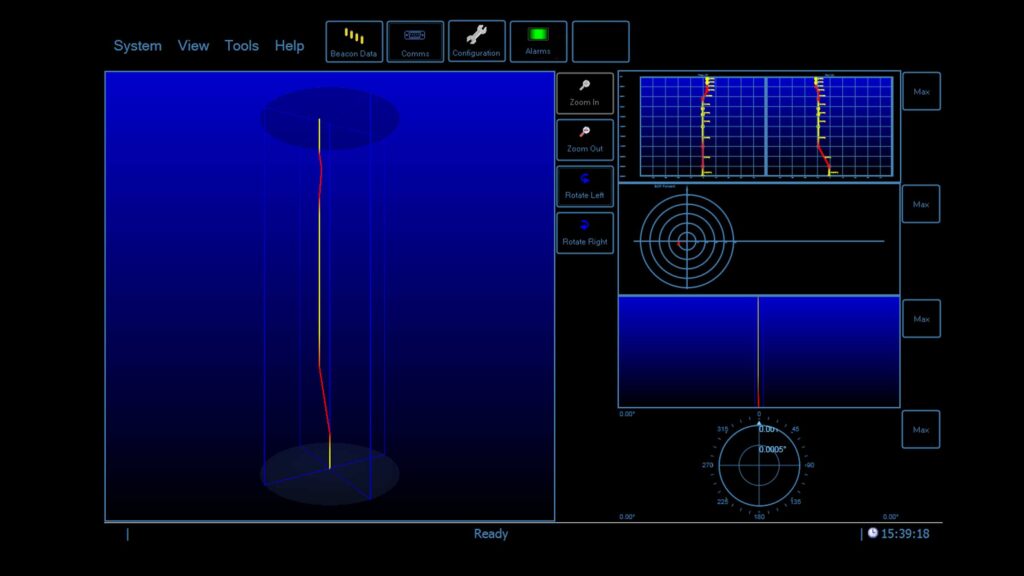

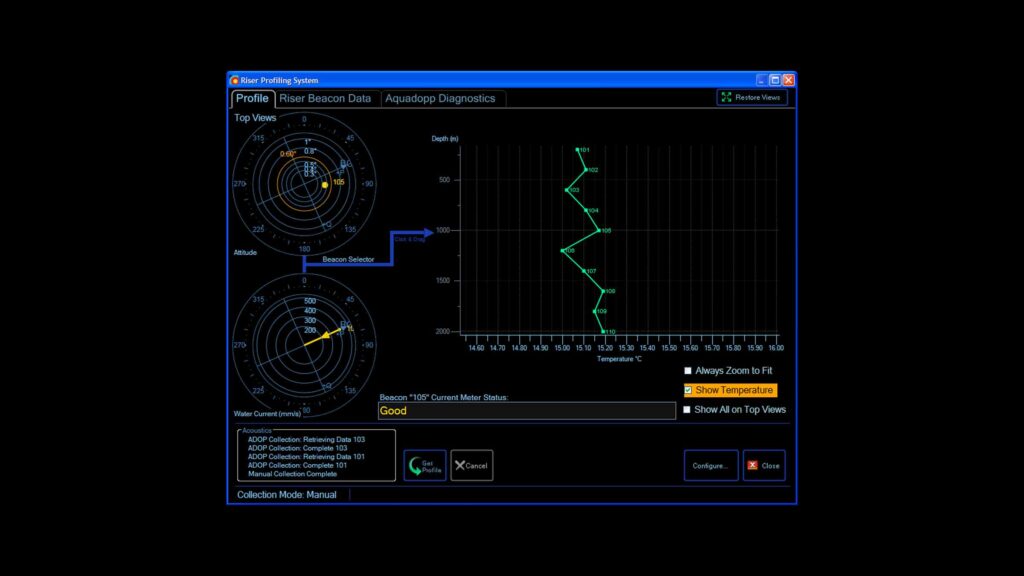

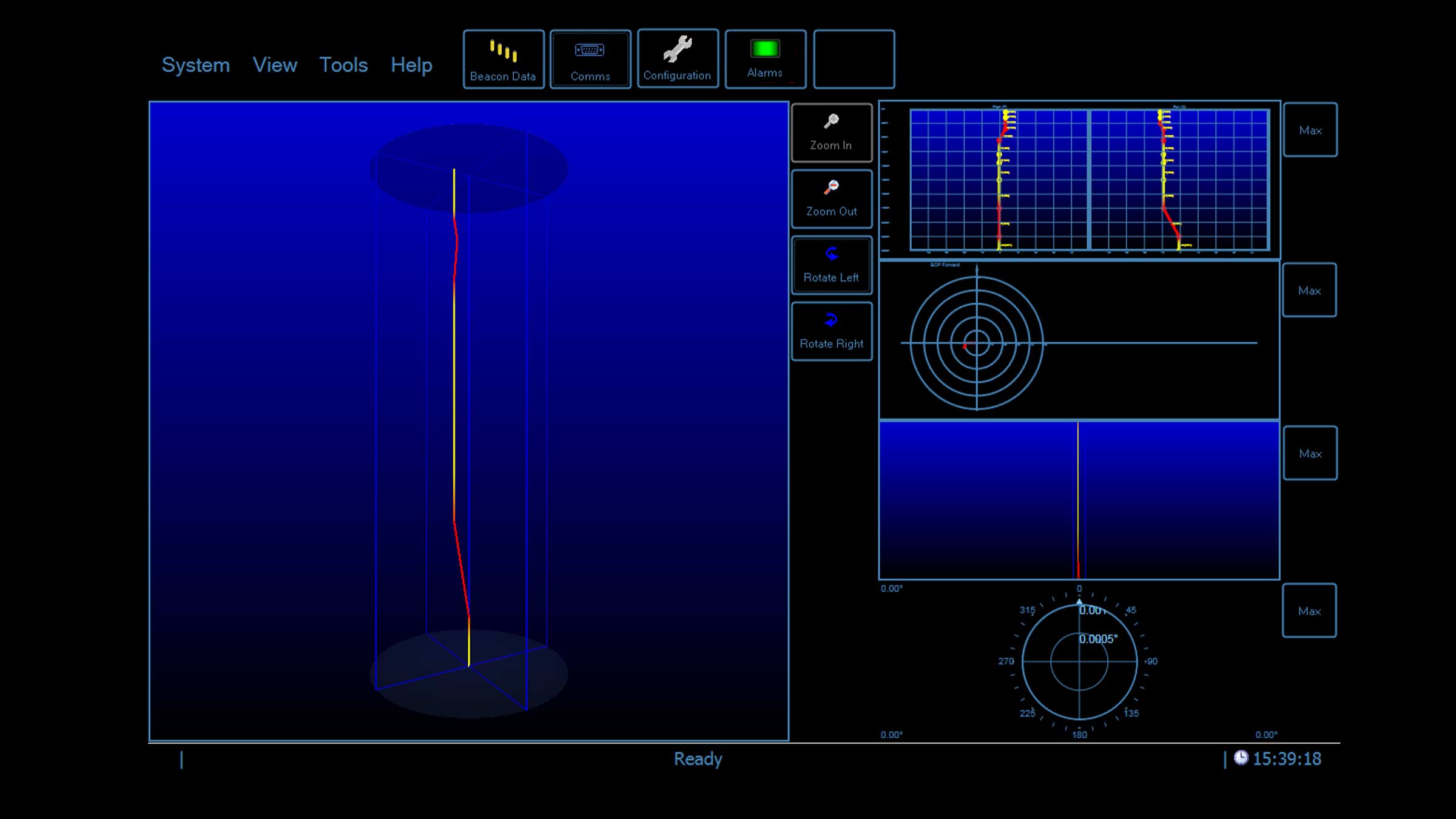

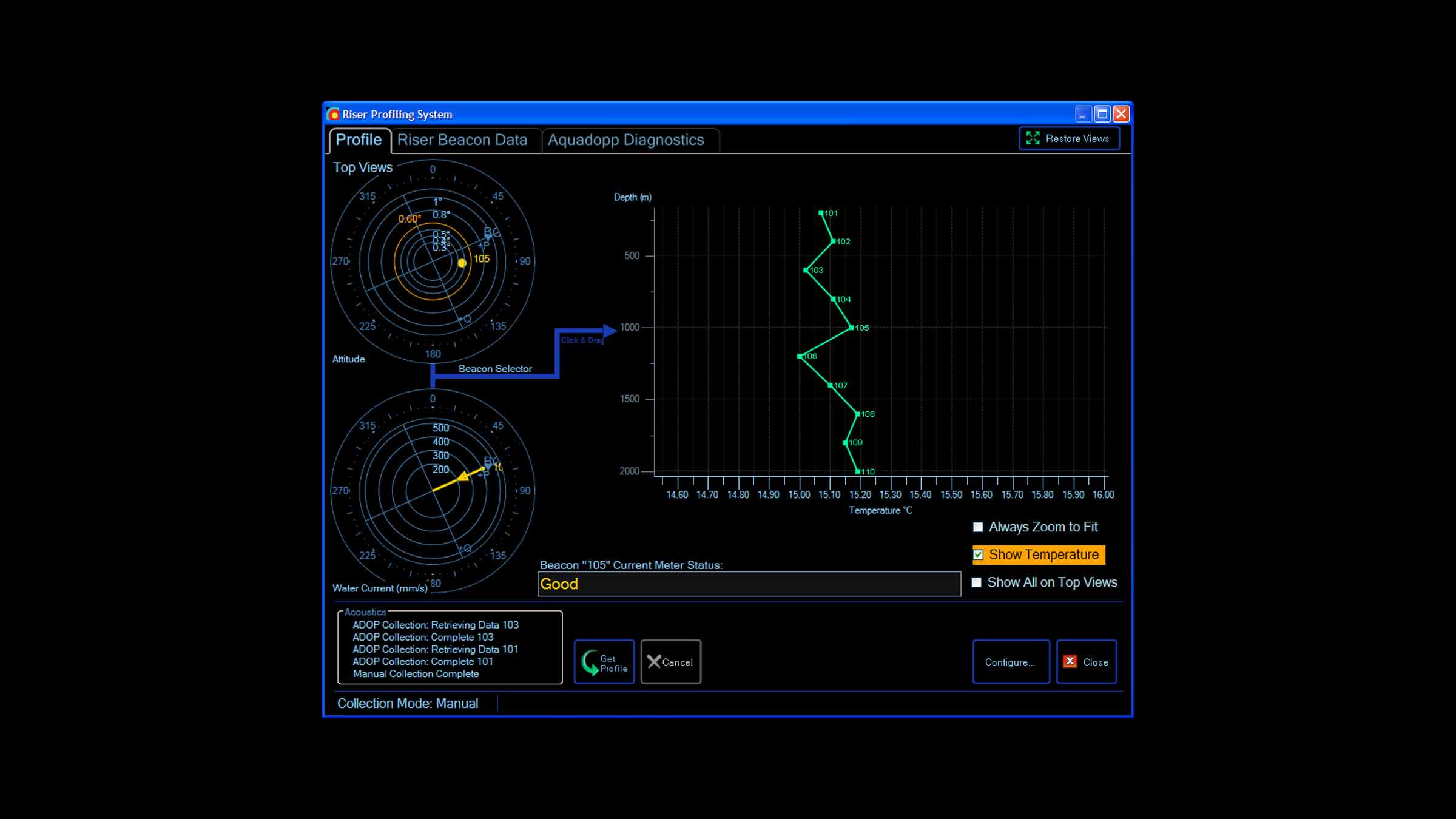

The Riser Profiling system can be used as a standalone, integrated within a Marksman LUSBL acoustic position reference system, or with a third-party integrated monitoring system.

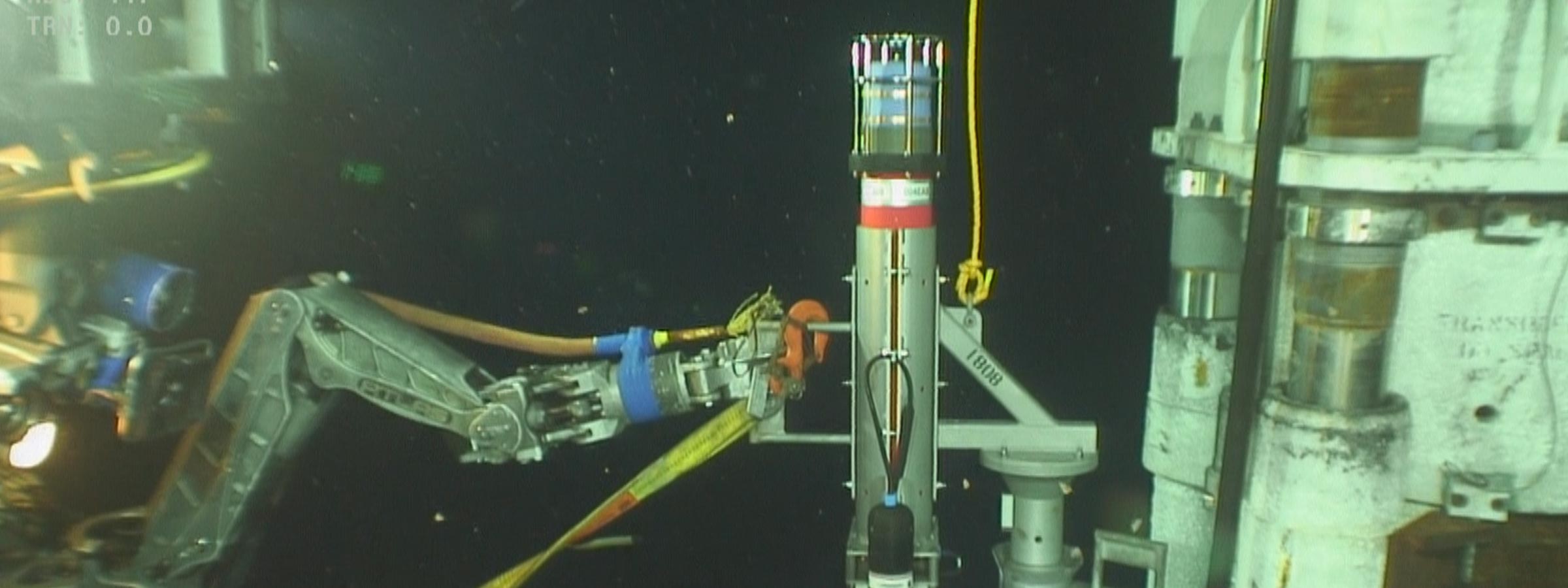

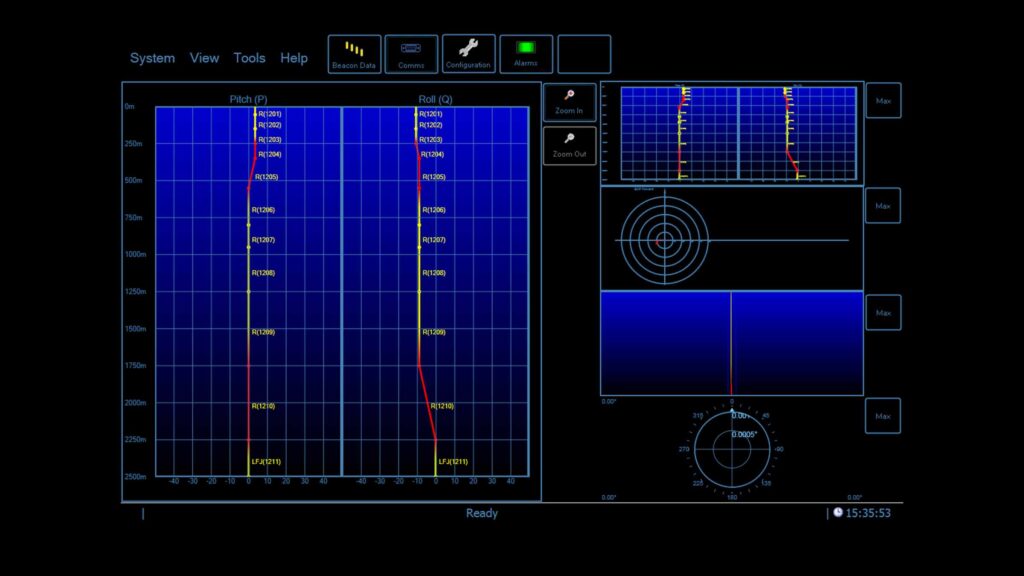

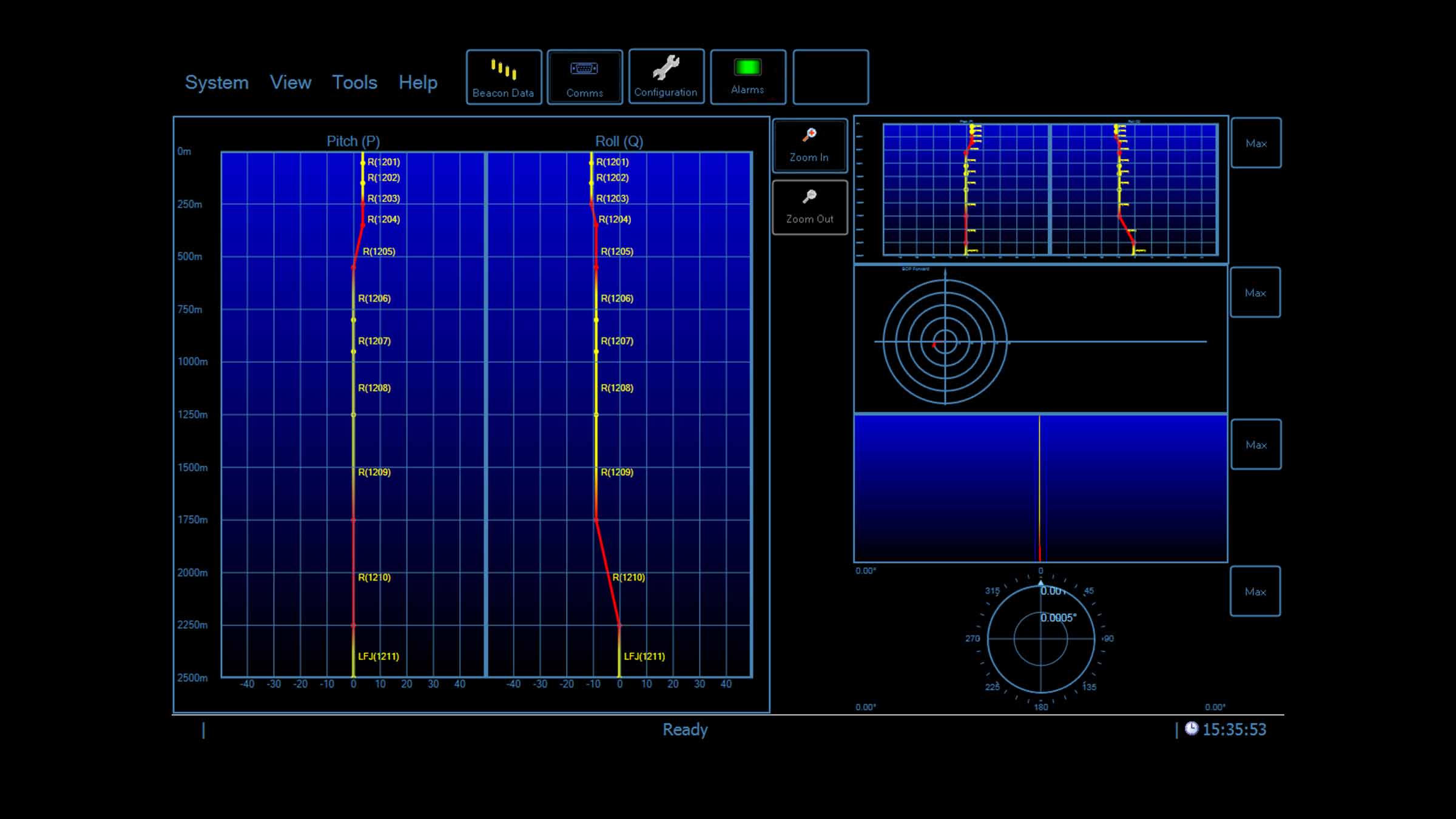

6th Generation (6G®) DPTi or SMART transponders wirelessly mounted along the length of the riser, provide highly accurate data. These are clamped onto the riser during deployment or installed via ROV subsea. Up to ten transponders are mounted on a riser. Each transponder is fitted with the following sensors:

- High-resolution dual axis inclinometer

- Water temperature

- Pressure and depth

- Optional single point Doppler current meter (speed, direction)

The gathered data is transmitted wirelessly from the transponders using our Wideband 2 acoustic signals to a transceiver on the vessel, eliminating the need for expensive umbilical cables to fitted up each riser.