In this first blog of our navigation series, we focus on our product calibration and why it’s so important for your operations.

In marine robotic operations, reliable and accurate navigation ensures reliable and accurate data collection. Therefore, it’s important the sensors providing navigation inputs to the marine robot are performing optimally each time they are deployed. Typically, an uncrewed underwater vehicle (UUV) will carry a Doppler velocity logger (DVL) and an inertial navigation system (INS) which require calibration each time the vehicle is moved to a new job, or the vehicle payload changes, to ensure that these two navigation sensors are in alignment. This process takes a number of hours.

We recognise that the time would be more valuable to users spent with the UUV on operations. This is why we ensure that every SPRINT-Nav unit is delivered pre-calibrated and will remain so for its operational life. Ready to go out of the box, first time and every time, SPRINT-Nav is our all-in-one navigation instrument for uncrewed underwater and surface vehicles. It combines carefully selected inertial sensors, Syrinx DVL and a high accuracy pressure sensor in a single housing. This creates the highest performing hybrid navigation instruments of their class on the market.

In this blog we dive first into how a good calibration improves operational efficiency and then look at why and how we calibrate at Sonardyne.

The importance of calibration

Hybrid navigation systems typically comprise separate sensors which are then integrated into the UUV individually. Any discrepancy between the sensors in the system may lead to errors in the navigation data and therefore errors in the data collected. In the worst-case scenario, poor navigation data could even lead to the loss of your UUV. We recognise that UUV operations are remote and expensive and therefore ensuring these discrepancies are removed is essential. This is why we go to the effort of ensuring every SPRINT-Nav product we deliver is pre-calibrated.

When a SPRINT-Nav is aided by all of its available internal sensors such as DVL, inertial and pressure sensors as well as one or more external aiding system Ultra-Short BaseLine (USBL), Long BaseLine (LBL) or global navigation satellite systems (GNSS), it will model and weight each observation it receives. This will tune Kalman filter states, biases in the inertial measurement unit (IMU) etc and will work to refine the calibration. However, when a SPRINT-Nav does not have any external aiding sources or the external aiding sources are of low quality, the fundamental alignment between of the DVL to the INS is essential in the long-term accuracy of all observations it produces. This accuracy is usually expressed as a percentage of distance travelled and is the key metric for informing the user that SPRINT-Nav is capable of the work it will be required to perform.

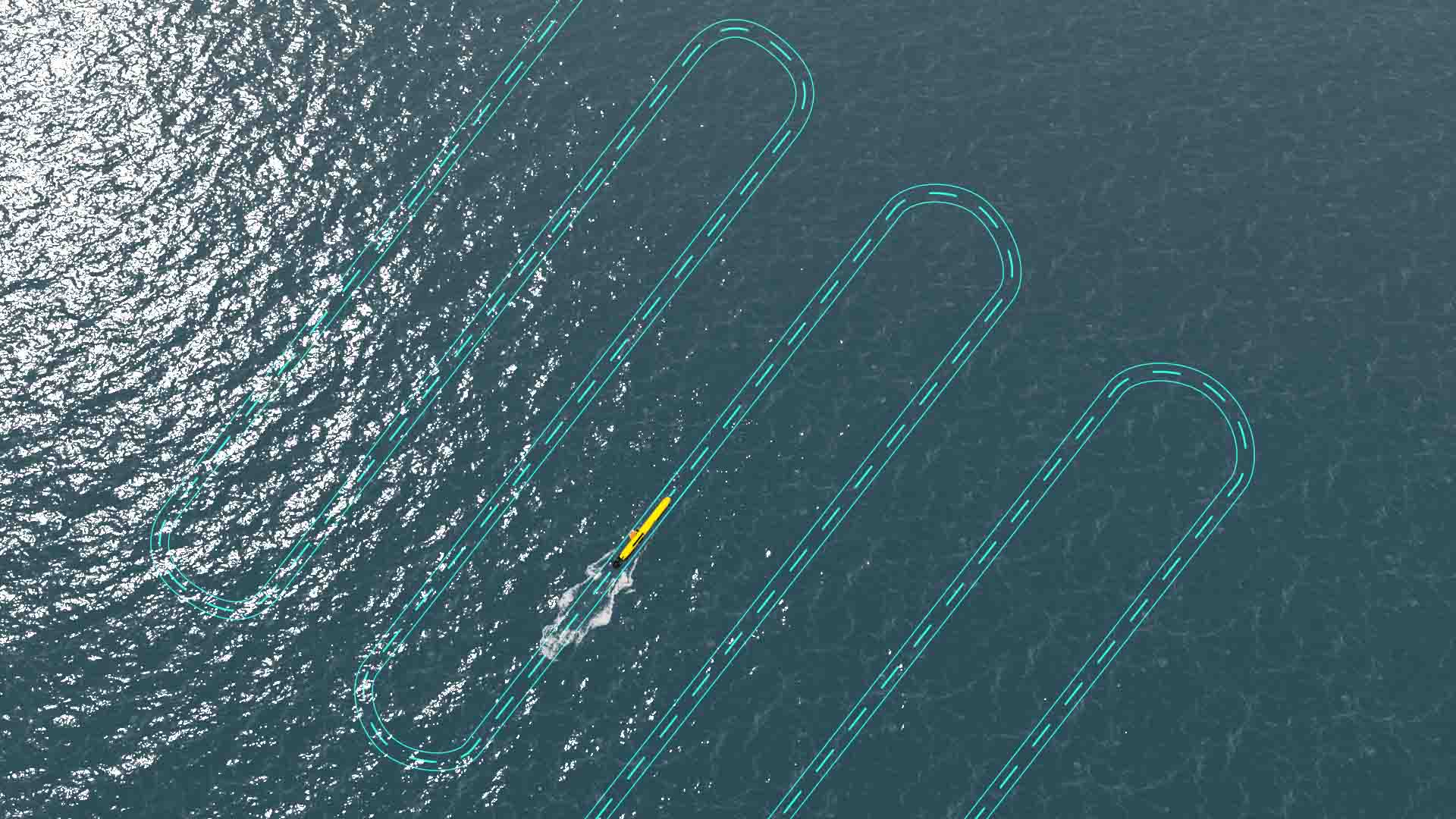

UUV conducting a site survey.

A Sonardyne calibration of your SPRINT-Nav will;

- Ensure heading, pitch and roll accuracy by reducing any misalignment between the DVL and INS.

- Enhance positional data by reducing drift over time and distance.

- Provide a stable position for guidance and control which is more resilient to external lower quality aiding systems.

Performing DVL-INS calibration effectively

The basis of every good calibration is solid mechanical design. Every SPRINT-Nav is designed to be mechanically robust and is machined in house, so units only need to be calibrated once and can be freely moved around without re-calibration.

When using separate DVL and INS units calibration is laborious and time consuming for the user. An operator on a vessel enters mechanical offsets between INS-DVL and then calibrates using long vessel runs in a variety of patterns.

This calibration routine produces heading, pitch, roll misalignments and a scale factor value after a period of time defined by the operator or once the misalignments converge to a value acceptable by the equipment manufacturer. The operator would then apply these vehicle and job specific calibration files before performing a verification run, typically in a linear trajectory, to ensure that the DVL-INS performance is within the specification for the work at hand.

Every SPRINT-Nav is calibrated at our test and calibration facility in Plymouth, UK. We tightly control external aiding sources (GNSS and sound velocity) meaning they are low bias and low noise allowing for a precise calibration.

A freshly calibrated SPRINT-Nav in Plymouth, UK

A typical SPRINT-Nav calibration takes approximately 20 hours to complete and encompasses varying seabed types, ranges of motion, altitudes, velocities and trajectories thus ensuring the SPRINT-Nav will perform across all operational and mounting scenarios.

Uniquely, we calibrate individual DVL beam alignments rather than just standard body frame misalignments. This guarantees each beam is independent and can work on its own or as a group. This in turn ensures tight coupling of the DVL to inertial sensors, increasing operational resilience by allowing navigation in areas where not all beams reliably track the seabed. Crucially, this allows for each DVL beam to be modelled correctly by the SPRINT-Nav as an individual velocity from a known angle.

Following the calibration, each SPRINT-Nav is verified on another area of seabed. This ensures its application over a range of operational scenarios. A Sonardyne engineer then confirms it is within the advertised specification.

Conclusion

As subsea industries de-carbonise and seek to become more autonomous, reliable robust navigation is crucial. SPRINT-Nav doesn’t just offer incredible value to your marine robot through being a one unit, one vendor solution – meaning less cables, reliable integration and one point of contact for support – but also through the benefit of our in-house calibration. Time spent by Sonardyne to manufacture, calibrate and verify every SPRINT-Nav before dispatch is time users don’t have to spend again and again in the field. This uniquely places the full SPRINT-Nav range at the forefront of subsea navigation.

This is the first blog in a series this year so stay in touch with what’s coming next and let us know if there’s anything you’d like to know about our navigation products – either personally or in our blog series.

In the meantime, if you’d like more information about SPRINT-Nav it can be found here.