Author: Stephen Auld, Global Business Manager, Subsea Asset Monitoring

As I’ve set out in the previous two blogs (Wireless Intelligence Made Easy and 21st Century Data Collection) in this three-part series, when you want to understand the fatigue life or integrity of your subsea systems you need two main elements. One is a way to accurately measure what’s actually happening, the second is a way to get that data from subsea to shore.

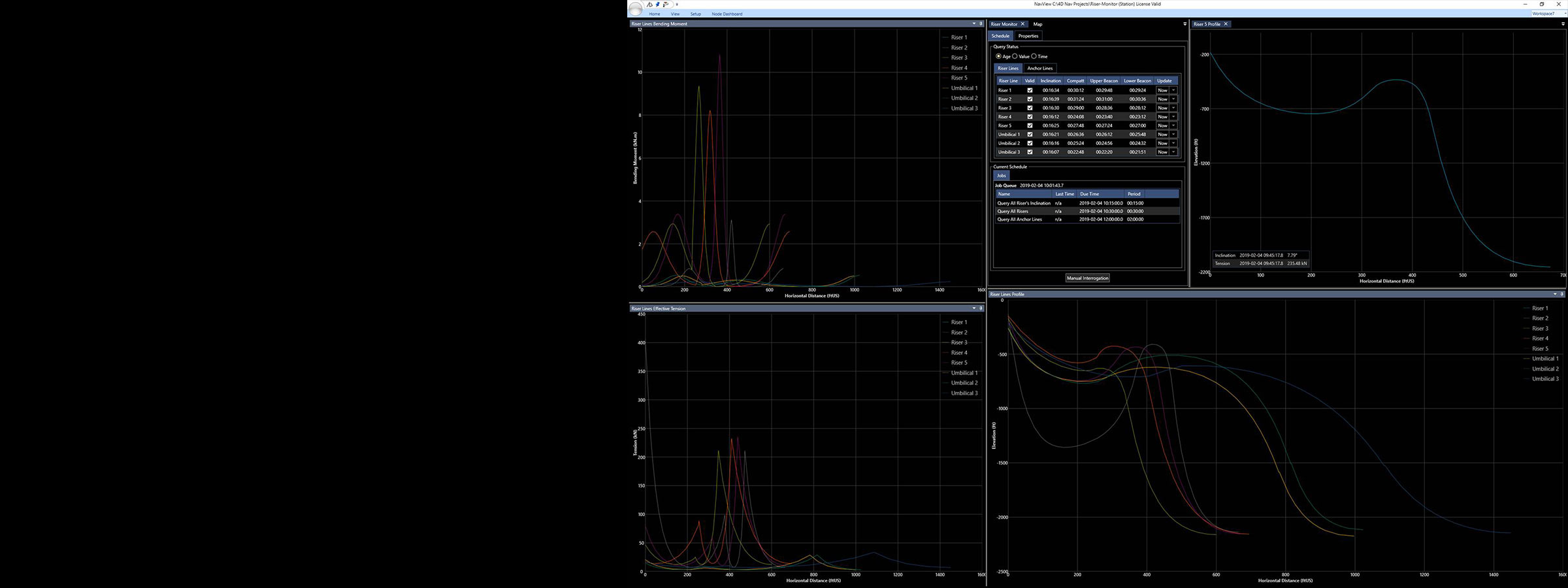

You also need a way to visualise the gathered information and understand what it all means. My previous two blogs focused on our SMART and AMT monitoring systems and different ways we can wirelessly access the data they gather for you, including using marine autonomous systems such as unmanned surface vessels (USVs) and autonomous underwater vehicles (AUVs).

For this third and final blog in the series, I’ll look at the final element you need; third-party analysts. Here’s where other companies, with their engineering and integrity experts, make use of the data our sensors gather to display, analyse, interpret and report to you on their findings. To put it another way, we measure, we monitor and we deliver data, either in raw or part analysed, summary form, to these trusted specialists.

Depending on what you want to know about your subsea system and how quickly, there are different routes you can take. Here are some options and examples of solutions we have provided to illustrate these various paths.

Challenge #1 – An operator was concerned about suspected and periodic vibration of a number of spool pieces within their deep water subsea field development.

- Solution #1 – the operator tasked their subsea inspection, repair and maintenance contractor with installing our monitoring technologies. This provided the data the operator’s external engineering consultancy needed to perform their fatigue analysis work to understand any impact on the spool pieces’ design life.

- Technology used – SMARTS and AMTs

- Data recovery method – Dunker 6 deployed from a production platform

Challenge #2 – An operator wanted real-time data so they could minimise fatigue on an aged wellhead caused by the blowout preventer (BOP) during a side-track drilling campaign.

- Solution #2 – they contracted a tethered-BOP system provider who contracted us to provide our monitoring technology. This enabled them, using third-party provided software, to view in near real-time any excessive BOP motion caused by drilling operations on the well, which could be stopped if the displayed fatigue exceeded a certain threshold.

- Technology used – SMARTS

- Data recovery method – Dunker 6 deployed from a drill rig

Challenge #3 – An operator wished to understand how much two flowline termination assemblies (FTA) were moving within their field development.

- Solution #3 – they used their subsea IRM contractor, who deployed our AMTs to measure movement of the FTAs. This resulted in the contractor designing a timely solution to inhibit the movement they had measured.

- Technology used – AMTs

- Data recovery method – seabed located SMART Dunker 6 hardwired through a control module

So, as I said, we measure, we monitor and we deliver data to your trusted specialists, whether that’s your in-house engineers, third party fatigue analysts or a specialist software provider. We provide them with the sensor information they need to perform their modelling and analysis. This in turn will inform the operator what they need to know about their subsea infrastructure.

Want to know more? Get in touch and we can provide robust sensors and through water, wireless, communication technologies to ensure the integrity and extend the fatigue life of your subsea assets.