Unite your navigation and positioning for seamless efficiency

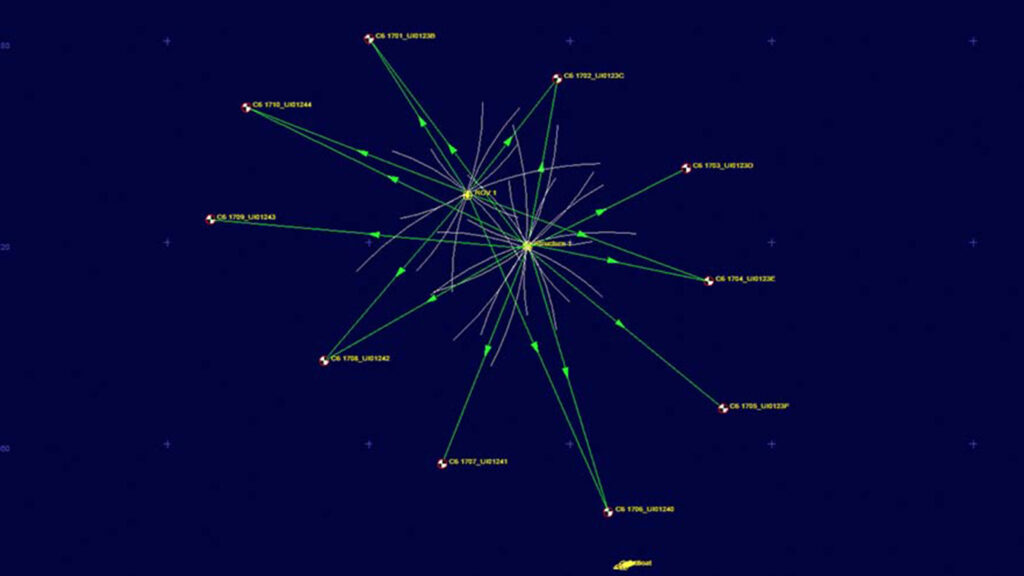

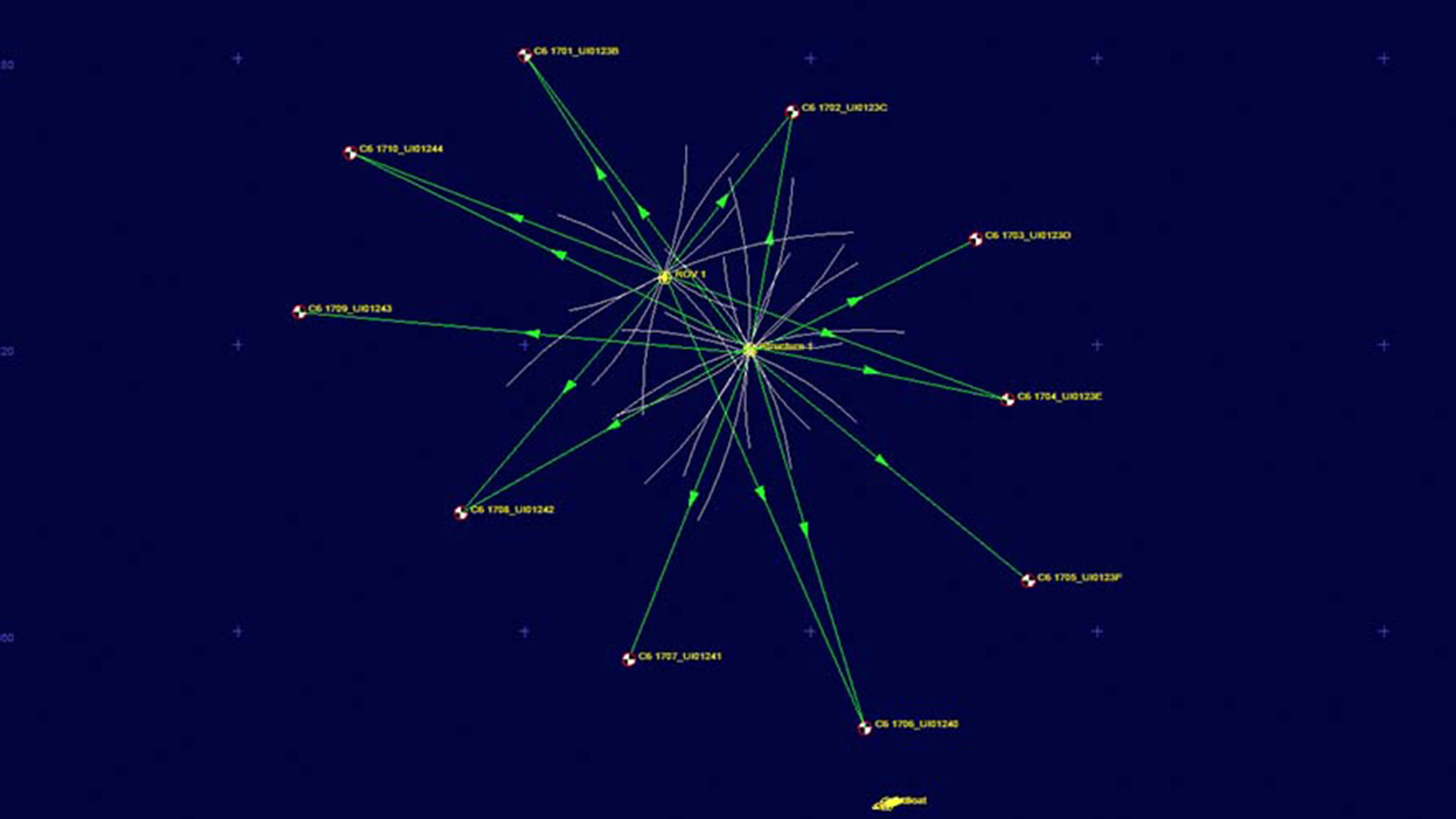

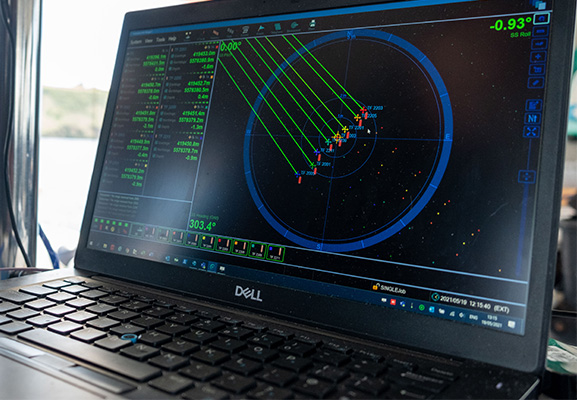

Fuse your workflow and control all your Long BaseLine (LBL), Sparse LBL, and SPRINT Inertial Navigation System (INS) projects from one intuitive interface. No more juggling multiple programmes – Fusion 2 simplifies your operations.

From subsea structure installation, metrology, pipeline and spool piece monitoring to pipeline positioning and more, Fusion 2 streamlines your subsea navigation and positioning. It connects LBL, Sparse LBL, and SPRINT INS for smooth workflows, real-time calibration and efficient deployments. This future-proof technology unlocks the potential of 6G+ and Wideband 3 instruments.

Real-Time Calibration: For faster, more efficient Sparse LBL operations, Fusion 2 allows real-time calibration of seabed transponders using Simultaneous Localisation and Mapping (SLAM). Eliminating delays and ensuring you collect accurate data from the start.

Enhanced efficiency through optimising hardware mobilisation. By consolidating control under one program, you require less equipment offshore, reducing costs and simplifying logistics, as well as saving you valuable setup time.

Built for our latest 6G+ instruments, Fusion 2 unlocks the full potential of Wideband 3 signal technology, ensuring your operations are at the forefront of subsea navigation.

Fusion 2 – fuse your systems for optimal performance

Why Fusion 2 is perfect for your operations

Do more with less – no need to operate two independent software and hardware systems to control your 6G LBL and SPRINT INS – Fusion 2 does it all in a single interface.

Fusion 2 LBL allows you to run calibrations in real time. Meaning you spend less time calibrating and more time collecting the right data, first time.

Lower your start-up costs: for practical, reliable LBL INS, Fusion 2 supports use of our SPRINT 300 with fewer transponders.

Backed by over 40 years of LBL system experience, Fusion 2 is the obvious choice for your offshore installation projects. Its 6G+ technology allows centimetric subsea positioning in all water depths. Highly robust and accurate instruments, professionally supported by our in-house engineers and surveyors, have made it the system of choice for subsea structure installations for decades.

Used with products such as GyroCompatt 6+, it provides you with centimetric positioning along with class leading Lodestar gyroscopes for heading, pitch and roll measurements all in a single, easy to deploy instrument.

If your underwater operations require precise measurements, an acoustic metrology system using several Compatt 6+ transponders can be placed in a network on the seabed / structures / hubs. The depths of the Compatts can then be accurately measured and 6G+ Wideband acoustic ranges collected between them.

Fusion 2 enables your seabed transponders to be SLAM calibrated in real-time for easier and faster Sparse LBL operations. And by embedding sensor data with high-update navigation ranging data, there’s no more interruptions to positioning updates at critical moments.

You’ll begin to see the benefits even before your project teams head offshore. Acoustic and INS projects can be configured and checked onshore prior to vessel mobilisation – saving you time, streamlining procedures and helping you to further de-risk operations.

If you need to tailor your operations, Fusion 2 enables multiple computations, comparing different set-ups, allowing you to pick the one you want. Sparse LBL might suit one operation more than LBL and vice versa. Now it’s easy to check, on-site, which works best for you.

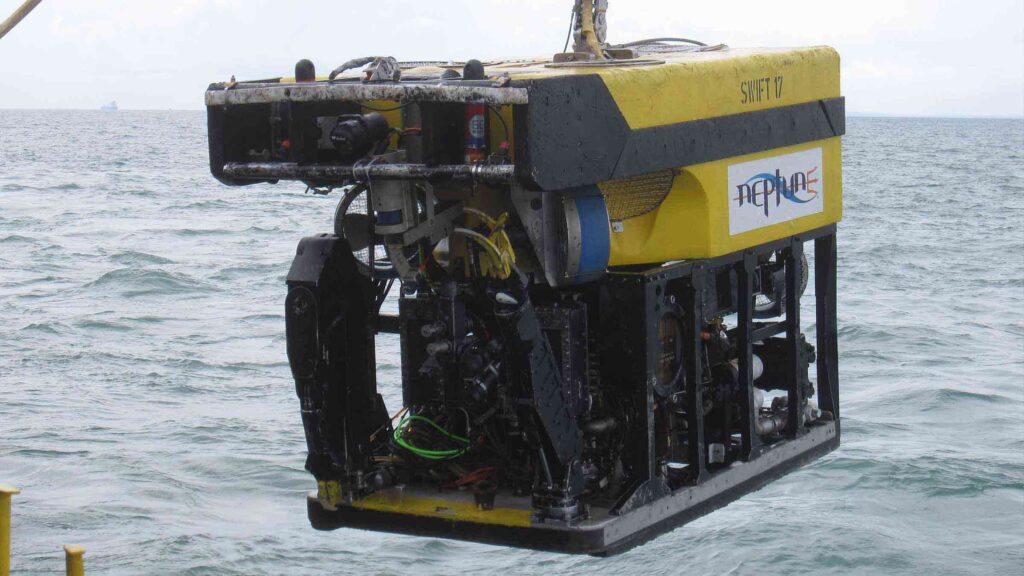

For optimal performance, Fusion 2 can be used with a number of our products – including Gyro Compatt 6+, Compatt 6+, SPRINT-Nav, ROVNav 6+ / mini ROVNav.

To further increase operational efficiency, digital signal processing protocol, Fusion 2 is best paired with Wideband 3, which you’ll find inside our trusted 6G platforms, Compatt 6+ and ROVNav 6+.

Wideband 3 gives you sensor data alongside navigation ranging data, providing your operators with real-time positions and sensor data at the same time. This allows the acceleration of update rates by a factor of ten, eliminating latency issues.

Fusion 2 in action

Rewriting the subsea survey rules

Read moreDeepwater structure installation made easy

Read moreRemote advances; operational advantages

Read moreSupport

• Work side-by-side with our Projects Group from concept to deployment

• Systems are manufactured and tested at our world-class in-house facilities before delivery

• Talk to our experienced team about our USV data harvesting service

• 24-hour support, wherever you are in the world

Design

• Optimised for 6G+ and Wideband 3

• Combined acoustic LBL and INS navigation

• Intelligent troubleshooting built-in

• Reduced hardware requirements

• Subsea hardware options

• High precision Compatt 6+

• High power, long-range ROVNav 6+ transceiver

• Combined LBL transponder and Lodestar AHRS Gyro Compatt 6+

Specifications

| Feature | Specification |

|---|---|

| Design | The most powerful INS and LBL system on the market |

| Seamlessly combines INS and LBL positioning techniques | |

| Incorporates 50 years of subsea navigation innovation and know-how | |

| Positioning for all phases of construction survey | |

| Full range of real-time array calibration options: SLAM, Baseline and Box-In | |

| Comprehensive EPSG geodesy database | |

| Calibration and positioning calculations in scale-free reference frame | |

| Performance | Better than 4 times precision improvement over USBL with SPRINT INS |

| Up to 3 cm Range-aided positioning accuracy with SPRINT INS | |

| Up to 3 cm LBL positioning accuracy | |

| Simultaneous LBL tracking of ROVs and structures with heading computation at up to 1 Hz | |

| Acoustics | Sonardyne Wideband 3 digital acoustics for reliable performance in all environments |

| Support for Multiuser Compatt 6+ | |

| Embedded Wideband 3 sensor data retrieval from Compatt 6+ for seamless tracking and faster calibration |

Frequently asked questions

Planning 6G beacon deployments

How to mount and extract an ISO image

SPRINT, SPRINT-Nav, Lodestar and Lodestar-Nav troubleshooting

How to use Fusion 2 LBL and INS dongles

Frequency management is obsolete. Here’s why.

What should I do if my Sonardyne security dongle expires or reports a problem?

How to download or upload files using Filezilla

Why am I getting old / incorrect data from my GyroCompatt 6+?

How to turn on a Lodestar Gyro Compatt using Ranger 2 or Fusion 2

I’m outputting a GGA from Fusion 2 / Ranger 2 to NaviPac but the position isn’t appearing in the correct location?

Will Compatt 6+ work with Ranger 2 and Marksman?

Can Compatt 6+ be used in the same LBL array as standard Compatt 6?

What is the difference between Compatt 6 and Compatt 6+?

If I’m using Fusion 2, can I choose to use Wideband 2 or Wideband 3 telemetry?

Will my ROVNav 6 work with Compatt 6+?

Will my ROVNav 6 work with Fusion 2?

How sparse is a sparse LBL array?

What software and firmware is compatible with SPRINT and Fusion 2 Systems?

Do I need to upgrade to Compatt 6+ and ROVNav 6+?

How to QC a Sound Velocity (SV) in Fusion 2

How far can my Compatt 6+ be above the seabed?

How to plan my sparse LBL array (guidance note)

How do I calibrate my sparse LBL array?

How do I set up structure deflection monitoring (SDM) in Fusion 2?

Do I need to use a scale factor in Fusion 2?

Can I use Compatt 6+ Multiuser in Fusion 2?

How do I perform a SLAM calibration in Fusion 2?

How to input or output time in Fusion 2

How do I perform an LBL calibration in Fusion 2?

How do I set up SPRINT-Nav in Fusion 2?

How do I set up sound speed collection and pressure to depth conversion in Fusion 2?

How to connect a SPRINT-Nav in Fusion 2

Software and firmware

Software and control hardware

Top tips

Transponders

Datasheets

Manuals and quick start guides

Innovation at work

We’ve engineered BlueComm 200 to push the boundaries of your underwater communication. Using advanced LED technology and sensitive photomultiplier tubes, you’ll achieve communication ranges up to 150 m. Its design houses the emitter separately from the receiver, ensuring optimal performance and reliability.

Fast and flexible – key features to power your mission

- Lightning-fast data transfer: 2.5 to 10 Mbps at ranges up to 150 m

- Optimal performance: Perfect for moderate to low turbidity dark water (>200 m depth or at night)

- Flexible deployment: Connect with your AUV, ROV, USV or surface dunker system

- Deep-rated capability: Ready for operations up to 4,000 m

- Speed of light technology: Experience unprecedented data transmission rates

Perfect for your platform

Perfect for your:

- Autonomous Underwater Vehicles

- Extra-large uncrewed underwater vehicles (XLUUV)

- Uncrewed Surface Vehicles

- Remotely Operated Vehicles

- Tracking and communications systems

Choose your perfect match:

BlueComm 200

When you need maximum range and performance in dark water conditions, our visible light system delivers up to 150 m range – ideal for video transfer and direct vehicle control. You’ll transfer data up to 10,000 times faster than acoustic systems, although ambient light may affect operating range.

BlueComm 200 UV

Working with lights on? Our UV variant maintains reliable communication even with artificial lighting present. Operating at ranges up to 75 metres, it’s your go-to solution for ROV and AUV applications requiring illumination, such as video recording missions.

Both systems offer incredible energy efficiency – transfer more than nine gigabytes of data using just one Lithium D cell battery.

Specifications table

| Feature | Type 8361 BlueComm 200 UV | |

|---|---|---|

| Depth rating | Up to 4,000 m operation | |

| Data rate | 2.5–10 Mbps | |

| Optical communication range | Up to 75 m | |

| Mechanical construction | Anodized aluminium or titanium | |

| Supply voltage | 24–36 V dc | |

| Communications interface | 10/100 Base-T Ethernet (static IP address) | |

| Command interface | Graphical user interface or Ethernet UDP command set | |

| Receiver unit | ||

| Receive wavelength | UV (band pass filter blocking visible light) | |

| Receive angle | 180° (omni-directional) | |

| Receiver weight in air/water | 7.3/3.1 kg | |

| Power consumption | 10 W | |

| Emitter unit | ||

| Optical transmit power | 6 W (radiated light) | |

| Optical wavelength options | 450 nm (royal blue), 400–800 nm (white) | |

| Emitter beam shape | 180° (omni-directional) | |

| Emitter weight in air/water | 3.6/2.6 kg | |

| power consumption | 30 W (bandwidth allocation dependant) | |

| Environmental and dimensions | ||

| Operating temperature range | -5 to 40°C | |

| Storage temperature | -20 to 55°C | |

| Dimensions (length x diameter) | Receiver | 384 x 136 mm |

| Emitter | 199 x 136 mm |

STP files

Datasheets

Manuals and quick start guides

Optics

• 450 nm (royal blue), 405 nm (UV) optical wavelength

• 180° (omni-directional) beam pattern

• 10 W / 15 W receiver / transmitter optical transmit power

Design

• Titanium and glass construction

• Subconn connectors

• 5.7 kg weight in water, emitter and receiver

Performance

• 2.5 – 10 Mbps data rate

• 4000 m depth rating

• Up to 150m optical communication range

Ownership

What’s in the box?

• Manual, 2 test cables and 2 sets of one emitter and receiver

• Warranty: 1 year return to Sonardyne service centre

• ITAR Controlled: No

• UK Export Licence: Not required

Modem 6 (subsea)

Modem 6 acoustic modems are a family of cost-effective solution for simple point-to-point data transfer from a wide range of sensors including, data loggers, ADCPs, CTDs and other subsea instruments.

Modem 6 (surface)

Modem 6 acoustic modems are a family of cost-effective solutions for simple point-to-point data transfer from a wide range of sensors including, data loggers, ADCPs, CTDs and other subsea instruments.

AvTrak 6

The most versatile instrument you can fit to your AUV. Built for simple integration on medium to large AUV platforms, all-in-one functionality comes as standard with AvTrak 6. It allows your AUV to undertake simultaneous LBL ranging, USBL tracking via a surface vessel and robust telemetry for AUV to vessel and AUV-to-AUV communications.

Overview

Its high power output and Wideband 3 signal processing offers improved operating range and acoustic performance in challenging conditions such as when deployed from noisy vessels or in multi-path environments.

The internal Lithium-ion rechargeable battery pack minimises the supply current for long dunker cables. It also enables relocation of the dunker if the cable is cut.

The robust AGP connector on the Dunker 6+ is identical to the ROVNav 6+ and HPT USBL for compatibility and to reduce spares.

At a glance

- Perfect for commanding LBL transponders

- Use it to recover data from Fetch and AMTs

- Capability to operate as topside for RT 6 acoustic releases

- Deploy it over-the-side of your vessel

- Rugged mechanics and connectors

- Shock mounted internal electronics

Dunker 6+ LBL and telemetry transceiver is fully compatible with our modem and sensor logging instruments such as AMT and Fetch , allowing it to be used to retrieve data or configure logging regimes. It can also be used to release the RT 6 range of acoustic releases.

The Dunker 6+ system consists of 100 m of cable on a stainless steel cable drum with brake and locking mechanism. The 10 m deck cable between the 48 V Surface Interface Unit (SIU) and the cable drum allows the drum to be conveniently located. The connection to the cable drum is via an easily replaceable 8-way SubConn.

Optionally, an RT 6 topside kit with 30 m of cable is available in a carrying case without a cable drum.

Specifications table

| Feature | Dunker 6 Type 8309-1351 / Dunker 6+ Omni-directional |

Dunker 6 Type 8309-1353 / Dunker 6+ Directional |

Dunker 6 Type 8309-1355 |

Dunker 6 Type 8309-1356 |

|

|---|---|---|---|---|---|

| Depth rating | 1,000 m | 1,000 m | 1,000 m | 1,000 m | |

| Operating frequency | MF (20–34 kHz) | MF (20–34 kHz) | LMF (14–19 kHz) | LMF (14–19 kHz) | |

| Transducer beam shape | Omni-directional | Directional | Omni-directional | Directional | |

| Transmit source level (dB re 1 µPa @ 1 m) |

187–196 dB (4 levels) |

190–202 dB (4 levels) |

187–196 dB (4 levels) |

187–202 dB (4 levels) |

|

| Tone Equivalent Energy (TEE) | 193–202 dB | 196–208 dB | 193–202 dB | 193–208 dB | |

| Receiver sensitivity (dB re 1 µPa) |

90–120 dB (7 levels) |

80–120 dB (7 levels) |

90–120 dB (7 levels) |

80–120 dB (7 levels) |

|

| Range precision | Better than 15 mm | Better than 15 mm | Better than 15 mm |

Better than 15 mm |

|

| Serial communications (software programmable) |

Primary port: RS485 (half-duplex) or RS232 Secondary port: RS485 (half-duplex) or RS232 or SYNC IN |

Primary port: RS485 (half-duplex) or RS232 Secondary port: RS485 (half-duplex) or RS232 or SYNC IN |

Primary port: RS485 (half-duplex) or RS232 Secondary port: RS485 (half-duplex) or RS232 or SYNC IN |

Primary port: RS485 (half-duplex) or RS232 Secondary port: RS485 (half-duplex) or RS232 or SYNC IN |

|

| Operating voltage | 24 or 48 V dc (±10%) | 24 or 48 V dc (±10%) | 24 or 48 V dc (±10%) | 24 or 48 V dc (±10%) | |

| External power | Active (listening) | <3 W typical (max 6 W when charging) |

<3 W typical (max 6 W when charging) |

<3 W typical (max 6 W when charging) | <3 W typical (max 6 W when charging) |

| Peak (during transmission | <80 W | <80 W | <80 W | <80 W | |

| Battery life Li-ion (listening) | 3 days | 3 days | 3 days | 3 days | |

| Connector type | AGP (8-way female) |

AGP (8-way female) |

AGP (8-way female) |

AGP (8-way female) |

|

| Mechanical construction | Super-duplex stainless steel | Super-duplex stainless steel | Super-duplex stainless steel | Super-duplex stainless steel | |

| Dimensions (length x diameter) |

692 x 200 mm | 660 x 200 mm | 586 x 200 mm | 641 x 230 mm | |

| Weight in air/water | 24/16 kg | 26/17 kg | 20/14 kg | 28/17 kg | |

| System kit | |||||

| Dunker 6, SIU, 100 m cable drum etc. |

602-0047 (8309-1351) |

602-0053 (8309-1353) |

n/a | 602-0072 | |

| Dunker 6+, SIU, 40 m cable drum etc. |

602-0135 (Dunker 6+ Omni-directional) |

602-0198 (Dunker 6+ Directional) |

n/a | n/a |

Frequently asked questions

STP files

Software and firmware

Software and control hardware

Datasheets

Manuals and quick start guides

Did you know?

Dunker 6+ can be used to recover data from Fetch and AMTs

Overview

Mini-ROVNav 6+ is designed to be significantly lighter and smaller than our standard ROVNav 6+ instrument, whilst providing full 6G LBL capabilities.

This makes it particularly suitable for inspection-class ROVs as well now uncrewed surface vessels (USVs) which can be configured to undertake routine LBL operations over-the-horizon from your survey vessel.

Its full support of Wideband 2 signal processing techniques offers long range and robust acoustic performance in challenging conditions such as on noisy vehicles or in multi-path environments.

At a glance

- Use it with Fusion 2

- Perfect when ROV space is limited

- USBL mode for emergency relocation

- Lightweight and easy to install

- Modem mode for data recovery from AMTs and Fetch instruments

Mini-ROVNav 6+ is also a fully compatible USBL responder or transponder compatible with Sonardyne Wideband 1 and 2 USBL systems and HPR 400. The internal Li-ion rechargeable battery pack also enables emergency transponder mode, so if the umbilical and therefore power is cut to the ROV it can still be located using a vessel equipped with a USBL system.

The integrated omni-directional MF transducer has a hemispherical beam pattern which is ideal for acoustics to an array and to a vessel alike.

Mini-ROVNav 6+ is fully compatible with our modem and logging equipment such as AMT and Fetch products, allowing it to be used to retrieve data or configure logging regimes. Data rates of between 100 to 9,000 bps user data rates can be supported depending on the environment.

Specifications table

| Feature | Type 8240 | |

|---|---|---|

| Depth rating | 3,000 m | |

| Operating frequency | MF (20–34 kHz) | |

| Transducer beam shape | Omni-directional | |

| Transmit source level (dB re 1 µPa @ 1 m) | 181–187 dB (2 levels) |

|

| Tone Equivalent Energy (TEE) | 187–193 dB | |

| Receiver sensitivity (dB re 1 µPa) | 90–120 dB | |

| Range precision | Better than 15 mm | |

| Operating voltage | 24 or 48 V dc (±10%) | |

| Serial communications | Primary port: RS232 (9,600 – 115,200 baud) | |

| Responder input | 4 V to 24 V, >0.5 ms duration |

|

| Release output | 12 V (250 mA rated) |

|

| Battery life (listening) Li-ion | >7 days | |

| External power | Active (listening) | <2 W |

| Battery charging | <6 W | |

| Peak (during transmission) | <50 W | |

| Mechanical construction | Hard anodised aluminium alloy and stainless steel connectors | |

| Serial communications bulkhead connector | MCBH8M | |

| Dimensions (length x maximum diameter) | 501 x 93.5 mm | |

| Weight in air/water | 5.1/2.2 kg | |

| Operating temperature | -5 to 40°C | |

| Storage temperature | -20 to 55°C | |

| Sensors | ||

| Temperature (±0.25°C) | Standard | |

| Strain gauge pressure sensor (±0.25% FS) | Standard |

Frequently asked questions

Software and firmware

Datasheets

Did you know?

Mini ROVNav 6+ can be used with Fusion 2 software

Overview

The instrument is a turn-key solution comprised of carefully selected high grade and highly reliable inertial sensors integrated into in-house designed inertial measurement unit (IMU).

The selected inertial sensors are the standard for commercial aviation with a proven 20+ year track record. These sensors have a highly desirable characteristic being insensitive to vibration, temperature changes and having very limited initial errors. The result is a system which is highly suitable for the marine environment where performance, robustness and data integrity need to be available from initialisation, even during the harshest conditions.

Lodestar requires no external aiding and settles robustly in dynamic conditions in less than five minutes. On-board data storage and backup battery functionality ensures continued operation and eliminates the risk of data loss even if communications or external power are lost. Power-pass through to external aiding sensors is supported to ease integration requiring only a single cable for comms and power.

If a full INS solution is required, Lodestar can easily be field upgraded to a SPRINT system (apart from Lodestar 200). This makes the Lodestar a flexible and future-proof solution for both ROV guidance and survey applications.

Lodestar has a proven track record spanning more than 10 years in the field in diverse applications from ROV guidance and autopilot to demanding survey applications. The instrument is available in 4,000 and 6,000 metre depth ratings with a variety of connector options and configurations.

At a glance

- Designed to aid subsea vehicle guidance: AUVs, ROVs and UUVs

- Uses high quality Honeywell gyro and accelerometers

- Sensors available in three performance levels: 200, 300 and 500

- Fast settling time so you can get straight to work

- Integrated DVL option available; Lodestar-Nav

- Factory upgradeable to SPRINT INS

Lodestar-Nav 200

Lodestar-Nav 200 provides all-in-one navigation solution for subsea vehicles by combining a Lodestar 200 AHRS with our Syrinx Doppler Velocity Log (DVL) and a high accuracy pressure sensor in a single housing. This saves cost, payload space and the complexity of integrating and operating separate sensors from different vendors.

Lodestar-Nav is pre-calibrated providing the ROV pilots with a robust and reliable solution, even in the most challenging operational scenarios, without needing to worry about sensor offsets.

Syrinx DVL inside that provides a large altitude range and high precision at all altitudes; this combines the best of 300 and 1200 kHz DVLs. Each DVL transducer is fitted with a full depth rated water block to ensure protection of the internal components and easy replacement if damaged.

Lodestar-Nav can be interfaced via a single connection and/or the DVL can be interfaced separately depending on requirements. Continuous on-board data storage supports post-mission diagnostics and post-processing.

Size

Measuring just 260 mm tall, the 4,000 m rated titanium housing allows easy fitment to any subsea vehicle. 6,000 m housing option.

Long life sensors

Lodestars and SPRINTs use Honeywell-supplied RLGs and inertial sensors with 400,000 MTFB, which have been proven in over 20 years in commercial aircraft.

Connectivity

Most Lodestars can be upgraded to SPRINT in the field as your requirements grow so there’s no need to remove and re-install a different instrument.

Specifications

| Feature | Lodestar 300 | Lodestar 500 | |

|---|---|---|---|

| Depth rating | 4,000 / 6,000 m | 4,000 / 6,000 m | |

| Heading | 0.2° | 0.1° | |

| AHRS settle time | <5 minutes in dynamic conditions | <5 minutes in dynamic conditions | |

| Roll and pitch | 0.01° | 0.01° | |

| Power requirement | 20–50 V dc, 15 W nominal, 35 W maximum | 20–50 V dc, 15 W nominal, 35 W maximum | |

| Power pass through | 3 x for external aiding sensors (up to 3A per sensor) | 3 x for external aiding sensors (up to 3A per sensor) | |

| Back up battery type/life | Li-ion/5 minutes | Li-ion/5 minutes | |

| Data storage | 8 GB internal memory | 8 GB internal memory | |

| Serial ports/protocol | 4x RS232 or RS485 | 4x RS232 or RS485 | |

| Other ports | 1x Ethernet, 4 triggers | 1x Ethernet, 4 triggers | |

| Output rate | Up to 100 Hz | Up to 100 Hz | |

| Output telegrams | Industry standard AHRS/INS telegrams including acceleration and rotation rates | Industry standard AHRS/INS telegrams including acceleration and rotation rates | |

| Connectors | 4x Seacon / Seanet, 1x Seacon / Seanet | 4x Seacon / Seanet, 1x Seacon / Seanet | |

| Mechanical construction | Titanium | Titanium | |

| Dimensions (diameter x height) |

4,000 m (Seacon) | 205 x 260 mm | 205 x 260 mm |

| 6,000 m (Seacon) | 205 x 280 mm | 205 x 280 mm | |

| 4,000 m (Seanet) | 205 x 250 mm | 205 x 250 mm | |

| Weight in air/water | 4,000 m | 18.5/11.5 kg | 18.5/11.5 kg |

| 6,000 m | 22/14 kg | 22/14 kg | |

| Operating temperature | -20 to +55°C | -20 to +55°C | |

| Storage temperature | -20 to +60°C | -20 to +60°C | |

| Shock rating | 22 g, 11 ms half sine | 22 g, 11 ms half sine |

Frequently asked questions

SPRINT, SPRINT-Nav, Lodestar and Lodestar-Nav troubleshooting

How to connect to the Lodestar within a Gyro USBL via an NSH

How to enter Transceiver & Lodestar Offsets for Optimised USBL

What cables do I need for my Lodestar?

How do I mate and calibrate a DVL to my Lodestar?

Can I power my subsea instruments with Lodestar or SPRINT?

How do I mate and calibrate a SPRINT or Lodestar to my Syrinx DVL?

What’s the difference between FOG and RLG?

STP files

Software and firmware

Software and control hardware

Manuals and quick start guides

Technical bulletin

Did you know?

Lodestar is highly optimised for cost, size, weight and power (C-SWaP)

Overview

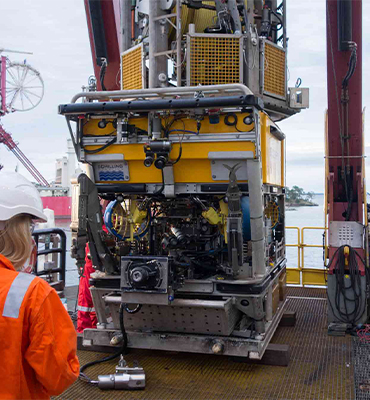

ROVNav 6+ uses our new Wideband 3 signal technology, which is key to unlocking the benefits of your Fusion 2 LBL system.

It allows, for the first time, sensor telemetry data (e.g. pressure, depth or temperature) from a seabed or structure deployed Compatt 6+ to be embedded within navigation (ranging) data. This change has a big impact on operations such as structure installation, as breaks in tracking to get sensor reading updates at vital moments are now a thing of the past.

Its compatibility with Wideband 3 and Wideband 2 telemetry commands, and support of high power Wideband 2 ranging protocols, proven for their accuracy and robustness, means the ROVNav 6+ offers improved range and acoustic performance in challenging conditions such as on noisy vehicles or in multipath environments.

At a glance

- High power, long range LBL transceiver for ROVs

- Wideband 3-enabled supporting embedded sensor data with ranging data

- Optimised for Fusion 2 and compatible with Fusion 1

- 3,000, 5,000 or 7,000 m depth rated options

- USBL mode for emergency ROV relocation

- Modem mode for harvesting data from Sonardyne logging sensors; Fetch, AMT…

ROVNav 6+ is also a fully functional USBL responder or transponder, compatible with Wideband 2 USBL systems and HPR400. The internal li-ion rechargeable battery pack also enables emergency transponder mode, so if the umbilical and therefore power is cut to the ROV it can still be located by USBL.

The omni-directional remote MF transducer makes installation on an ROV easy. ROVNav 6+ is designed to be rugged and relatively lightweight and utilises robust underwater connectors. ROVNav 6+ supports a range of internal sensors including: strain gauge pressure, PRT temperature and MEMS based inclinometer.

ROVNav 6+ is also fully compatible with our modem and logging equipment such as AMT and Fetch products, allowing it to be used to retrieve data or configure logging regimes. It supports all of our Wideband 2 and Wideband 3 spread spectrum acoustic communication; 100 to 9,000 bps data rates can be selected depending on the environment.

Sensor options include a Digiquartz pressure sensor, precision inclinometer and altimeter interface. This provides a fully featured ROV manipulator deployable tool/sensor pack for a range of different applications including metrology, bathy survey and structure deployment operations, without the requirement for any additional interfacing on the ROV.

Specifications table

| Feature | 8340-3161 | 8340-5261 | 8340-7261 |

|---|---|---|---|

| Depth Rating | 3,000 m | 5,000 m | 7,000 m |

| Operating Frequency | MF (20–34 kHz) | MF (20–34 kHz) | MF (20–34 kHz) |

| Transducer Beam Shape | Omni-directional | Omni-directional | Omni-directional |

| Transmit Source Level (dB re 1 µPa @ 1 m) | 187–196 dB (4 levels) | 187–196 dB (4 levels) | 187–196 dB (4 levels) |

| Range Precision | Better than 15 mm | Better than 15 mm | Better than 15 mm |

| Serial Communications | RS232 or RS485 (half-duplex) | RS232 or RS485 (half-duplex) | RS232 or RS485 (half-duplex) |

| Battery Life Li-ion (Listening) | 3 days | 3 days | 3 days |

| Operating Voltage | 24 or 48 V dc (±10%) | 24 or 48 V dc (±10%) | 24 or 48 V dc (±10%) |

| Serial Communications Connector | Subconn (8-way female) | Subconn (8-way female) | Subconn (8-way female) |

| Remote Transducer Connector | Burton (3-way male) | Burton (3-way male) | Burton (3-way male) |

| Housing Mechanical Construction | Hard anodised aluminium 6082 | Hard anodised aluminium 7075 | Hard anodised aluminium 7075 |

| Remote Transducer Mechanical Construction | Stainless steel 316 | Stainless steel 316 | Stainless steel 316 |

| Dimensions (Maximum) (Length x Diameter) | 768 x 200 mm | 768 x 200 mm | 768 x 200 mm |

| Weight in Air/Water | 14.3/5.3 kg | 14.7/5.7 kg | 15.5/6.0 kg |

Frequently asked questions

If I’m using Fusion 2, can I choose to use Wideband 2 or Wideband 3 telemetry?

Can ROVNav 6+ be used with standard Compatt 6s?

Will my ROVNav 6 work with Fusion 2?

Do I need to upgrade to Compatt 6+ and ROVNav 6+?

Where should I install my ROVNav 6+ transducer?

What are the differences between a ROVNav 6+ and Mini ROVNav 6+ ?

How to QC a Sound Velocity (SV) in Fusion 2

How far can my Compatt 6+ be above the seabed?

How do I perform an LBL calibration in Fusion 2?

STP files

Software and firmware

Transponders

Datasheets

Manuals and quick start guides

Technical bulletin

Did you know?

ROVNav 6+ is compatible with Fusion 1 and can be depth rated up to 7,000 m

Overview

WMT is a 6G compatible, high acoustic output power USBL transponder available in two depth versions: 3,000 m and 7,000 m. The 7,000 m version has a higher acoustic output power level for improved long-range operation.

For ROV and towfish tracking, WMT supports responder trigger for faster position updates, an integrated rechargeable Li-Ion battery pack that is charged from the ROV’s power supply and full RS232 communications enabling channel set up, power and gain etc. to be changed from the surface.

At a glance

- Use it with Ranger 2 for deep water, long layback tracking tasks

- High power acoustic output and directional transducer

- Responder mode for fast position updates

- Full two-way Sonardyne Wideband 2 interrogation and reply

- Li-Ion rechargeable battery pack

- Optional remote transducer

An on/off switch (3,000 m only) helps to ensure the battery pack is not discharged when not in use. If an umbilical trigger is not available, then the full Wideband transponder mode provides excellent USBL performance in a small, lightweight package.

Remote omni or directional transducers are available for WMT. These make installation on a ROV easier as the remote transducer can be installed where there is good line-of-sight and is easily replaced if damaged. The main body of the transponder can then be installed within the ROV frame where it is well protected from damage.

Specifications table

| Feature | Type 8190-3111 | Type 8190-3112 | Type 8190-7212 | |

|---|---|---|---|---|

| Depth Rating | 3,000 m | 3,000 m | 7,000 m | |

| Operating Frequency | MF (20–34 kHz) | MF (20–34 kHz) | MF (20–34 kHz) | |

| Transducer Beam Shape | Omni-directional | Directional | Directional | |

| Source Level (re 1 µPa @ 1 m) |

High Power | 187 dB | 193 dB | 199 dB |

| Low Power | 181 dB | 187 dB | 193 dB | |

| Tone Equivalent Energy (TEE) WBv2+ |

High Power | 193 dB | 199 dB | 205 dB |

| Low Power | 187 dB | 193 dB | 199 dB | |

| Range Precision | Better than 15 mm | Better than 15 mm | Better than 15 mm | |

| Depth Sensor | ± 0.5% full scale | ± 0.5% full scale | ± 0.5% full scale | |

| Communications Interface | RS232 (9,600–115,200 baud) | RS232 (9,600–115,200 baud) | RS232 (9,600–115,200 baud) | |

| External Supply Voltage | 24 or 48 V dc (± 10%) | 24 or 48 V dc (± 10%) | 24 or 48 V dc (± 10%) | |

| External Power | Sleep | ~650 mW | ~650 mW | ~650 mW |

| Wideband Listening | ~1 W | ~1 W | ~1 W | |

| Battery Charging | 6 W | 6 W | 6 W | |

| Peak (During Transmission) |

<50 W | <50 W | <50 W | |

| External Power Switch | Yes | Yes | No | |

| Battery Life (Li-ion 15 V) |

Listening | 30 days | 30 days | 30 days |

| Continuous 5 Seconds Interrogation |

Approx. 6 days at low power | Approx. 6 days at low power | Approx. 6 days at low power | |

| Mechanical Construction | Anodised aluminium alloy and plastics | Anodised aluminium alloy and plastics | Anodised aluminium alloy and plastics | |

| Operating Temperature | -5 to 40°C | -5 to 40°C | -5 to 40°C | |

| Storage Temperature | -20 to 55°C | -20 to 55°C | -20 to 55°C | |

| Dimensions (Diameter x Length) | 94 x 501 mm | 94 x 513 mm | 98 x 513 mm | |

| Weights in Air/Water | 5.1/2.2 kg | 7.0/3.5 kg | 7.0/3.5 kg | |

| Options | Remote, Cable Connected Transducer (see separate datasheet) |

Remote, Cable Connected Transducer (see separate datasheet) |

None |

Frequently asked questions

Software and firmware

Software and control hardware

Datasheets

Manuals and quick start guides

Technical bulletin

Did you know?

WMT is used with Ranger 2 USBL for tracking and communications

Overview

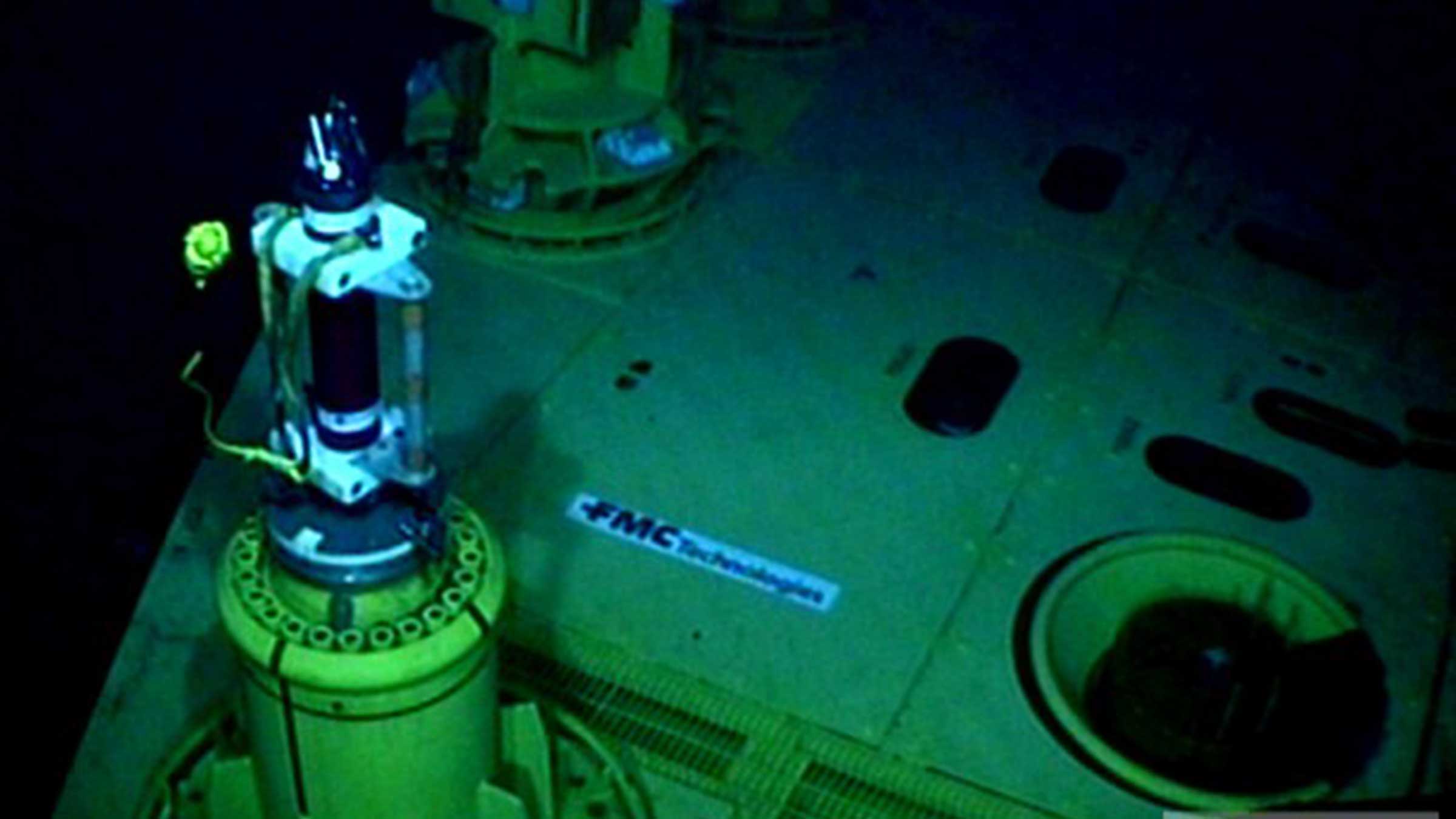

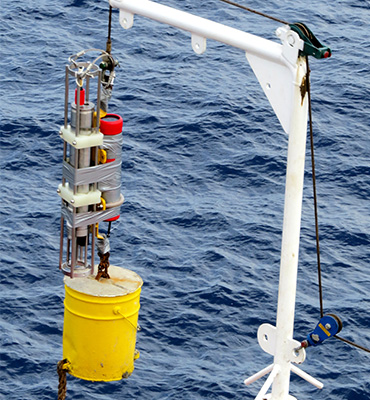

Compatt 6+ is used for high precision survey and construction operations in all water depths, including: spool piece metrology, pipeline touchdown monitoring, structure installation and dynamic positioning reference.

Compatt 6+ offers significant time saving with fast update rates (up to 1 Hz LBL tracking), all made possible using the Wideband 3 acoustic telemetry protocols. Support of Wideband 2 ranges maintains backwards compatibility. This makes any system operating with Compatt 6+ significantly easier to operate therefore de-risking operations, reducing vessel time and reducing training requirements for offshore personnel.

At a glance

- Compatible with all 6G LBL, INS and USBL systems

- Wideband 3 enabled

- Versatile, flexible and cost-effective

- Over 3,600 different configurations available

- Choice of depth ratings to 7,000 m

Our Wideband advanced signal processing offers improved acoustic performance in challenging conditions, longer ranges, improved multipath rejection around structures and real-time range diagnostics for quality control. Wideband also reduces the interference to and from adjacent Sonardyne and other acoustic positioning systems.

The integrated communications and navigation technology allows the transponder to be used as a multi-purpose modem, autonomous data logger and navigation reference transponder.

Wideband 3

For the first time, sensor telemetry data (e.g. pressure, depth or temperature) is embedded within ranging data so no more waiting for sensor readings at vital moments.

Compatible

Compatt 6+ transponders are backwards compatible with your existing Compatt 6 inventories so you can mix and match in the field.

Upgradable

We can upgrade your existing Compatt 6 into plus units quickly and cost effectively meaning you can go on to realise the full benefits of Fusion 2.

Overview

Compatt 6+ is used for high precision survey and construction operations in all water depths, including: spool piece metrology, pipeline touchdown monitoring, structure installation and dynamic positioning reference.

Specifications table

| Feature | Type 8300-3111 | Type 8300-3113 | Type 8300-5213 | |

|---|---|---|---|---|

| Depth rating | 3,000 m | 3,000 m | 5,000 m | |

| Operating frequency | MF (20–34 kHz) | MF (20–34 kHz) | MF (20–34 kHz) | |

| Transducer beam shape | Omni-directional | Directional | Directional | |

| Transmit Source level (dB re 1 µPa @ 1 m) | 187–196 dB (4 levels) |

190–202 dB (4 levels) |

190–202 dB (4 levels) |

|

| Tone Equivalent Energy (TEE) | 193–202 dB | 196–208 dB | 196–208 dB | |

| Receive sensitivity (dB re 1 µPa) | 90–120 dB (7 levels) |

80–120 dB (7 levels) |

80–120 dB (7 levels) |

|

| Ranging precision | Better than 15 mm | Better than 15 mm | Better than 15 mm | |

| Number of unique Wideband 2 addresses | >300 | >300 | >300 | |

| Battery life (listening) | Alkaline | 833 days | 833 days | 833 days |

| Lithium | 1,390 days | 1,390 days | 1,390 days | |

| External power supply | 24 V | 24 V | 24 V | |

| Safe working load (4:1) | 250 kg | 250 kg | 250 kg | |

| Operating temperature | -5 to 40°C | -5 to 40°C | -5 to 40°C | |

| Storage temperature | -20 to 55°C | -20 to 55°C | -20 to 55°C | |

| Dimensions (maximum) (length x diameter) |

With sensor guard | 1,034 x 200 mm | 1,018 x 200 mm | 1,018 x 200 mm |

| Without sensor guard | 1,034 x 178 mm | n/a | n/a | |

| Weight in air/water | 23.8/11.8 kg | 27.0/14.0 kg | 29.0/15.0 kg | |

| Endcap sensors and options | ||||

| Temperature (±0.1°C) | Standard | Standard | Standard | |

| Tilt switch (±30–45°) | Standard | Standard | Standard | |

| Strain gauge pressure sensor (±0.1%) | Standard | Standard | Standard | |

| High precision strain gauge (±0.01%) Presens or Keller |

Optional | Optional | Optional | |

| Paroscientific digiQuartz pressure sensor 1,350 m, 2,000 m, 4,130 m, 6,800 m (±0.01%) |

Optional | Optional | Optional | |

| Inclinometer (tilt sensor) range ±90°, accuracy: ±1° |

Standard | Standard | Standard | |

| High accuracy inclinometer

range: ±90°, accuracy: ±0.05° over 0 – ±15°; ±0.2° over 0 – ±45° |

Optional | Optional | Optional | |

| Sound velocity sensor ±0.02 m/s accuracy under calibration conditions | Optional | Optional | Optional | |

| Release mechanism | Standard | Standard | Standard | |

| Power for external sensors | Standard | Standard | Standard | |

| Gyro input | Standard | Standard | Standard |

Frequently asked questions

Compatt 6 and 6+ Deployment Tests

Frequency management is obsolete. Here’s why.

6G Terminal Lite Range Test

When to use a float, when to use a stand?

How can I get the best performance from my long layback tracking operations?

How can I deploy my Compatt 6+ using iWand?

How to correctly set a Compatt 6+ release mechanism

Does Compatt 6+ have modem capabilities?

How often do endcap sensors need calibrating to keep them in spec?

Is it possible to position Compatt 6+s independently within the same array and send each positioning out of Fusion to our navigation software?

Will Compatt 6+ work with Ranger 2 and Marksman?

I want to buy standard red Compatt 6, are they still available for sale?

Can Compatt 6+ be used in the same LBL array as standard Compatt 6?

What is the difference between Compatt 6 and Compatt 6+?

If I’m using Fusion 2, can I choose to use Wideband 2 or Wideband 3 telemetry?

Can ROVNav 6+ be used with standard Compatt 6s?

Will my ROVNav 6 work with Compatt 6+?

Do I need to upgrade to Compatt 6+ and ROVNav 6+?

How to QC a Sound Velocity (SV) in Fusion 2

How far can my Compatt 6+ be above the seabed?

How to replace a battery in Compatt 6 and 6+ family of transponders

How to plan my sparse LBL array (guidance note)

How do I calibrate my sparse LBL array?

How do I set up structure deflection monitoring (SDM) in Fusion 2?

Can I use Compatt 6+ Multiuser in Fusion 2?

How do I perform a SLAM calibration in Fusion 2?

How do I set up sound speed collection and pressure to depth conversion in Fusion 2?

Software and firmware

Software and control hardware

Transponders

Manuals and quick start guides

Did you know?

Compatt 6+ uses Wideband 3 technology

Reassuringly reliable Ranger 2

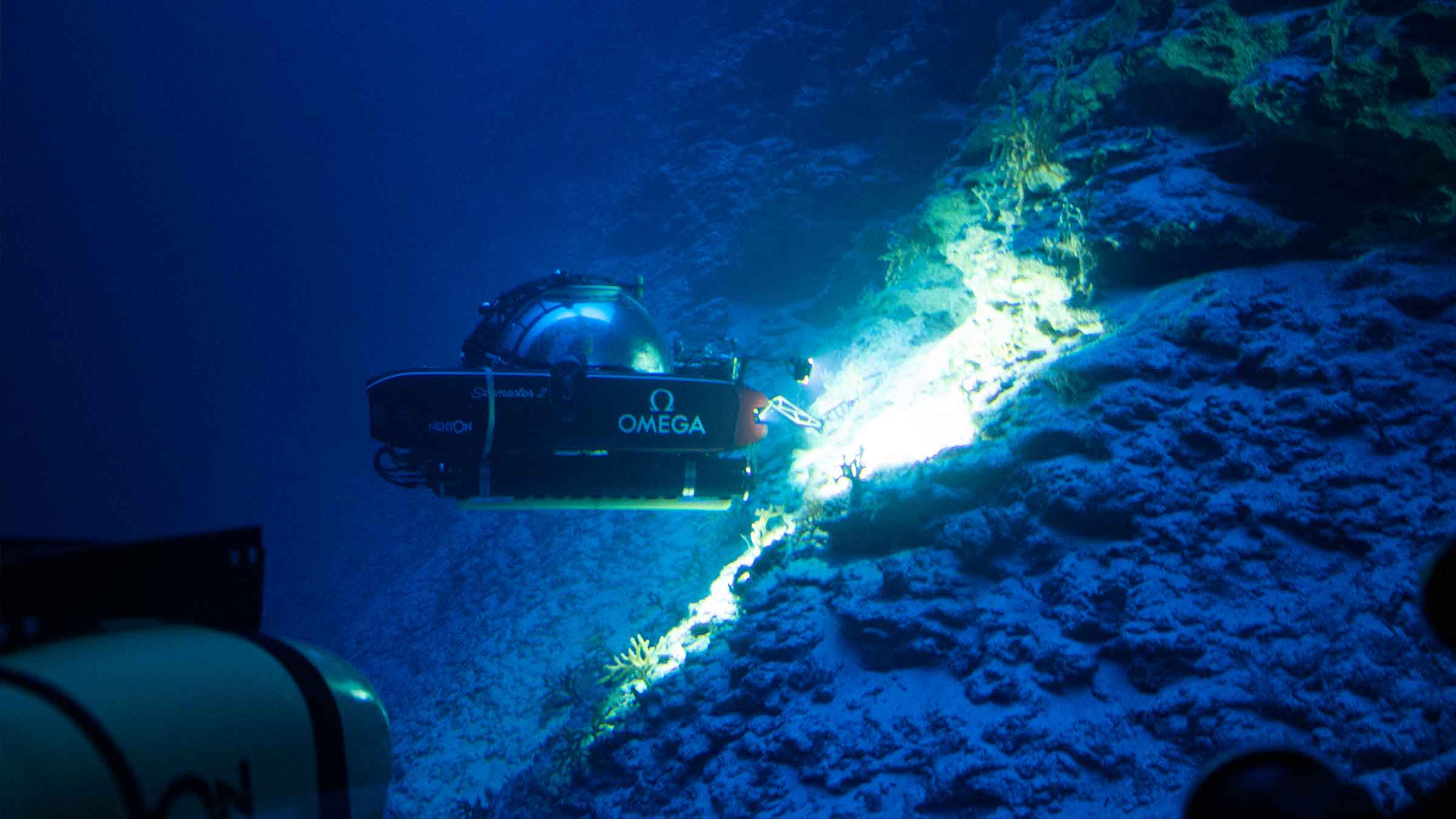

Ranger 2 is more than just an acoustic tracking and positioning system. It goes way beyond tracking; it can be part of a dynamic positioning system, it supports robust two-way data communication with a range of seafloor sensors to collect data, it can support AUV command and control and will even release seabed moorings.

Ranger 2 can even be run from an uncrewed surface vehicle (USV) enabling truly remote, autonomous operations. Whether your mission involves seabed surveys, offshore energy site inspections or commanding a fleet of AUV’s, Ranger 2 can help you expand them over the horizon and to the edges of your imagination.

It comes with an impressive list of standard features, our award-winning 6G (sixth generation) acoustic hardware platform and Sonardyne Wideband 2 digital signal architecture. The flexibility of the Ranger 2 family is further extended by our range of 6G transponders to support a wide variety of applications.

Why should you invest?

Our Ranger 2 family gives you the versatility you need, at the investment level you can afford, to get your project completed quickly and efficiently. It’s engineered like no other USBL on the market. Adaptable, scalable and always compact, there is a Ranger 2 USBL to suit any size vessel or project. As your needs grow, bolt-on software packs unlock additional capability and protect your investment. Whichever size suits you best, they will always be compatible with our full range of 6G transponders and many other vessel systems.

Micro-Ranger 2 USBL

The ‘baby’ of the Ranger 2 family and the ideal entry-level USBL, Micro-Ranger 2’s compact size contradicts its impressive performance. It may be our smallest underwater tracking system to date, but it will have a big impact on your operations.

Never used a USBL system before? No problem. Micro-Ranger 2 is simple to setup and use.

Need to know where your targets are? Micro-Ranger 2 has them covered. Precision, ease of use and versatility come as standard. It’s built around the same market-leading hardware and digital acoustic technology you’ll find in our family of deep water USBL systems, but for significantly less cost and complexity.

For the full picture of what your Micro-Ranger 2 USBL is capable of, please visit its dedicated product page.

Mini-Ranger 2 USBL

Mini-Ranger 2 is our mid-level USBL target tracking system, perfect for nearshore operations; UXO surveys, search and recovery and structure inspections. With a 995 m operating range, extendable to 4,000 m, it can track up to ten underwater targets simultaneously, including divers, towed instruments, ROVs and AUVs.

Choose to add the Marine Robotics software pack and it will communicate with subsea robotic platforms, sharing positions and exchanging data.

A compact, easily installed, system it’s your ideal choice for temporary installation on small survey vessels, as well as USVs.

For the full picture of what your Mini-Ranger 2 USBL is capable of, please visit its dedicated product page.

Ranger 2 USBL

Ranger 2 is the largest USBL in the family and the most powerful USBL on the market. Able to simultaneously track up to 99 targets with up to 11,000 m range, it is anything but standard.

Recommended for installation on large vessels and USVs, Ranger 2 incorporates over 30 years of our USBL innovation and know-how. It has a global vessel track record and is used for offshore energy, research, cable-lay, salvage and naval operations, to name but a few.

Sharing a common platform with other Sonardyne USBLs, Ranger 2 supports all industry standard DP telegrams and acoustically aided inertial navigation systems (INS).

For the full picture of what your Ranger 2 USBL is capable of, please visit its dedicated product page.

6G

Our 6th generation (6G) technology provides faster, secure and robust data communications from seabed to surface . This gives you speedier updates on the location of your assets and access to your vital data.

Wideband

Our wideband technology enables digital high-throughput data, range resolution and accuracy with low latency. Teamed with our 6G it gives you fast, reliable, accurate data over greater distances.

Robotics

Uncrewed, autonomous surface and underwater vehicles are increasingly used for coastal, deep sea and over-the-horizon operations, reducing costs, risks and carbon footprint. Thats why we have a dedicated “bolt on” pack for our Ranger 2 to enhance your robotics operations.

Dynamic positioning

We’ve been engineering high integrity position reference systems for dynamically positioned vessels since the early 1990s. Our USBL, LUSBL and SPRINT- INS products provide dynamic positioning solutions for a range of vessels and environments.