In my last blog, we looked at how unattended sensors could help to solve some of our 21st century war fighting challenges, not least how to maximise the use of our crewed and uncrewed assets. We also showed how sensors already exist that can meet those challenges today. In this blog, let’s look at what we need to consider to make them work for you.

There are three things you need to understand:

- 1.Nature is against us

Location: We mean it. Live organisms thrive in shallow waters. It doesn’t take long for biofouling to occur. Typically, this starts with the formation of biofilms, followed by the adhesion of micro-organisms. In shallow water environments, at higher temperatures, it takes just three weeks for biofilm to form and then attract larger colonizers, which in turn attract much larger organisms causing macrofouling. There is little that can be done once the larger organisms take hold, other than recover the instrument and physically remove them. In time they will affect sensor performance and may even stop sensors working altogether. In some regions, biofouling can limit effective deployments to fewer than three months. In cooler and deeper waters, the rate of bio-fouling growth drops, making longer deployments possible. Where an unattended sensor is deployed and how biofouling may affect it needs to be considered as this will determine the duration of deployment.

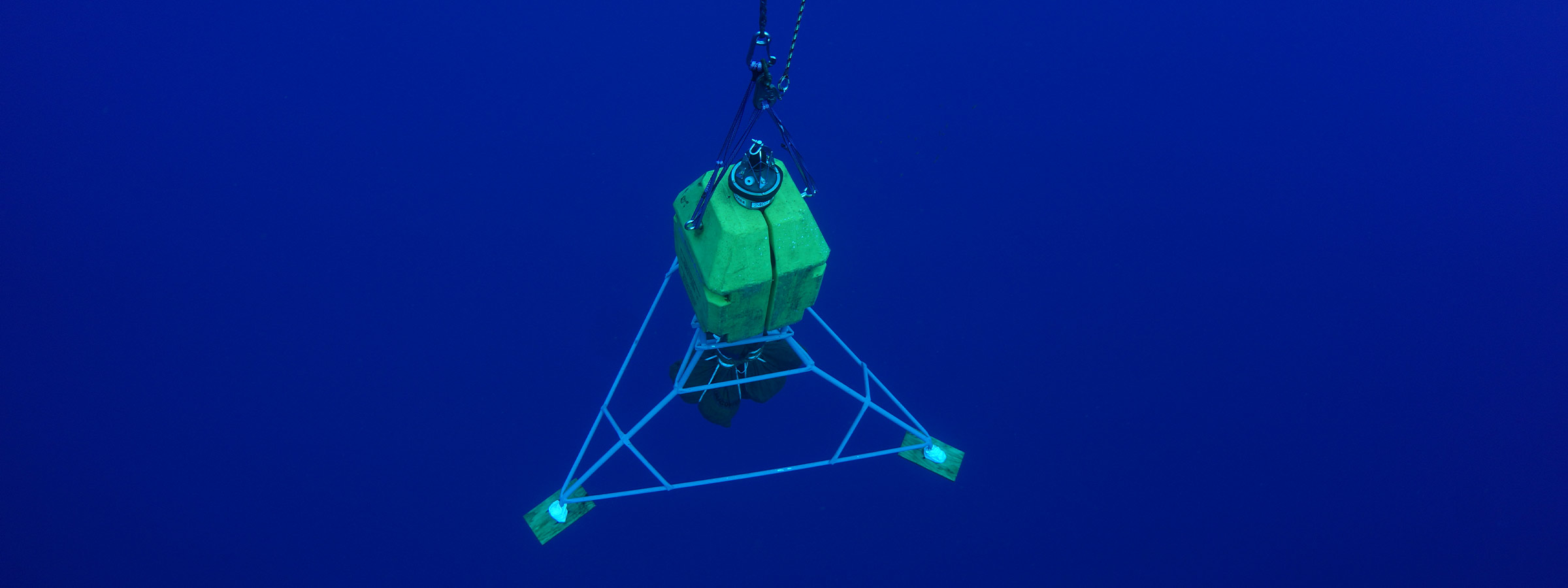

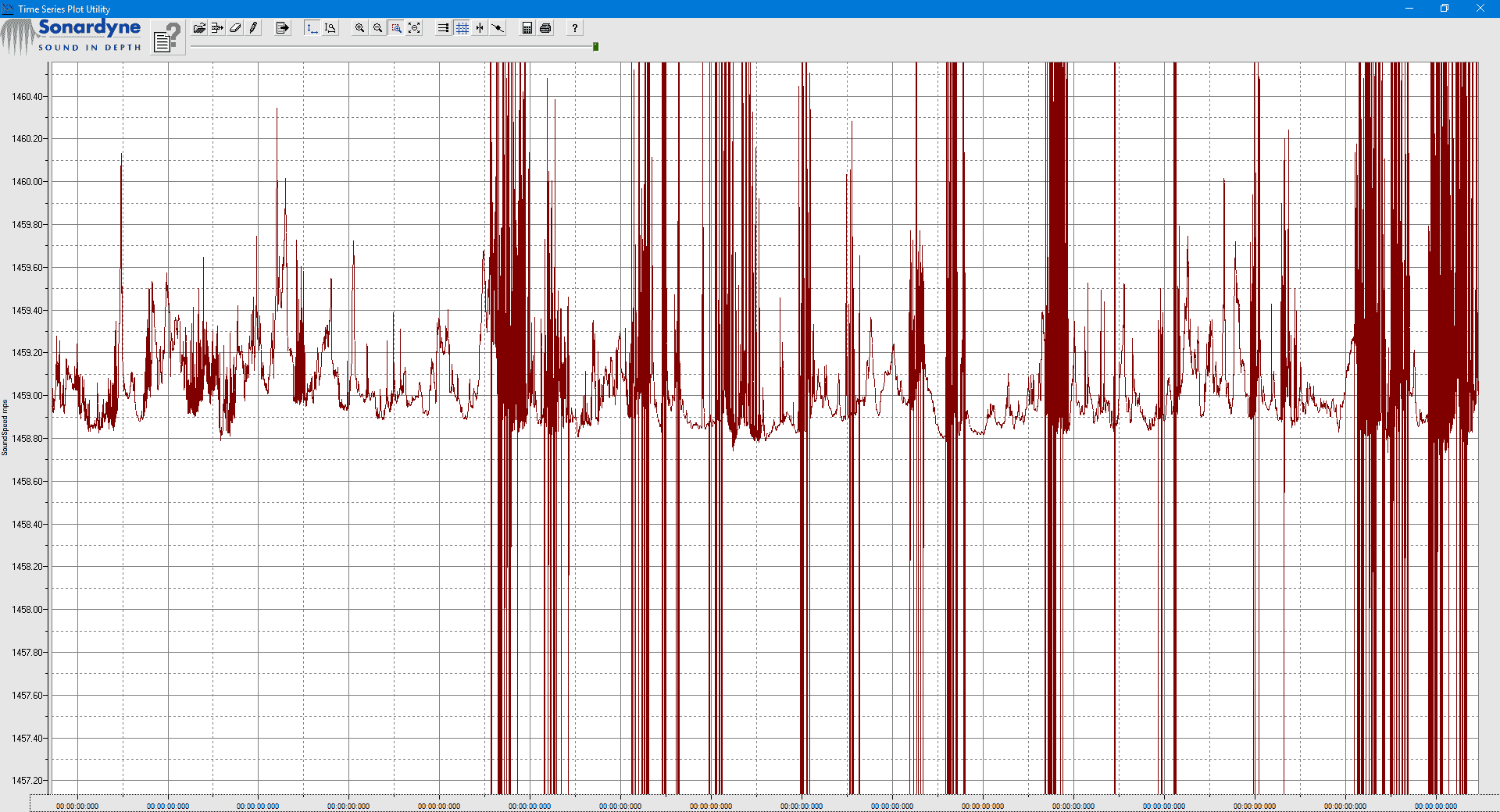

The impact of biofouling on a sound velocity sensor can be very clear.

The impact of biofouling on a sound velocity sensor can be very clear.

Materials: Choosing the right materials to build your instruments with can also impact biofouling growth rates. In addition, the right materials are also critical to ensuring your instruments do not corrode. Iron corrodes when exposed to water. Any material with iron in it is subject to corrosion. Over time, even stainless steel will corrode and rust. For long-endurance missions, the design and manufacture of underwater unattended sensors needs to factor in these considerations to ensure that systems remain corrosion free.

Pressure: Then there is pressure. As we dive, we add about one atmosphere of pressure for every 10 m of water depth. Sensors must be designed to both withstand extreme pressures at thousands of meters of water depth, but also to rapidly cycle through pressurisation and depressurisation, as they are deployed and recovered. This is no mean engineering feat.

Seabed conditions: The seabed can be an unforgiving place – it is varied and complex. Unattended sensors can sink through mud or sand. Corals and rocks can obstruct your line of sight and act as reflectors to acoustic sensors. It is not always flat either and deploying a sensor on a slope or close to a cliff could have an impact on your operations.

Commercial activity: Unfortunately, it is not just nature we have to contend with. Interaction with commercial fishing activity can be a challenge. Many underwater sensors have ended up caught in fishing gear. We know, because we’ve had them knock on our door claiming salvage rights for some of our commercial instruments!

Anti-trawl frames are used to prevent fishing interaction.

Anti-trawl frames are used to prevent fishing interaction.

- 2. Design for endurance

Delivering an underwater sensor to the bottom of the ocean is analogous to deploying a satellite in space. Design practices are similar because the choices we make today are going to be ones we have to live with for the next 10 years. This means there is no room for error. The electronics, the batteries, the connectors and the subsea housing all have to be up to the task. Making the right decisions comes with experience, but also by following practical engineering principles.

Long endurance, tried and tested.

Long endurance, tried and tested.

Start by modelling your operations. Modelling the environment and how your instruments will interface with it is critical as it enables us to work through concepts and designs ahead of fabrication and testing; enabling us to quickly consider new technologies that keep rapidly evolving around us.

Make sure you conduct in-water tests. Once your systems are designed and fabricated, they need to be rigorously tested to their breaking limits. This is our chance to understand the envelope in which they will continue working. Use pressure chambers, vibration tables and temperature-controlled facilities. Consider accelerated cycle testing. Use proof-of-concepts.

Once you are ready, it’s time to go out to sea and deploy your instruments. While typically not as expensive as launching a satellite, this is still a costly endeavour requiring significant planning and effort. It needs to be right.

- 3. So much data

A sensor deployed at sea for 10 years can gather a lot of data. Exactly how much will be limited by the amount of memory on your storage device. Running out of data storage can be avoided by carefully considering which data to store and at which sampling rate. Continuous sampling of data typically also drives higher power consumption, draining valuable battery resource.

This is why edge computing is becoming so important. On-board algorithms can be used to determine at which rate to sample, increasing the frequency if certain events are triggered. On the other hand, processing raw data and turning it into useful information massively reduces storage requirements. A good unattended sensor should be equipped with the capability to store and process all data or store only the useful information.

Information can also trigger events. For example, the unattended sensors can be made to release data pods that float to the surface to relay information. Alternatively, they may contact nearby unattended sensors in a subsea acoustic network to hop data from out in the field to a base station. For certain missions, data can be harvested from unattended sensors using uncrewed surface vessels (USVs) or uncrewed underwater vehicles (UUVs) and then the sensor’s memory banks cleared, to continue the mission beyond its original design. In all cases, you need to consider what information is required and what data you need to get it.

Collecting your data with a UUV or USV offers more options

Collecting your data with a UUV or USV offers more options

Making sensors work for you

Unattended sensors are difficult to engineer, but ultimately it’s worth the work. They can support a multitude of missions such as oceanography, anti-submarine warfare, intelligence, surveillance, target acquisition, and reconnaissance (ISTAR) and field deployed ranges.

Want to find out more about our capability? Join us in the next instalment of this series or get in touch.

Missed the previous instalment? No problem, click here