It’s been brought to our attention that people think that Fusion 2 has taken away the need for a surveyor’s skills for long baseline (LBL) operations. Seeing it in action, maybe you could be forgiven for thinking that.

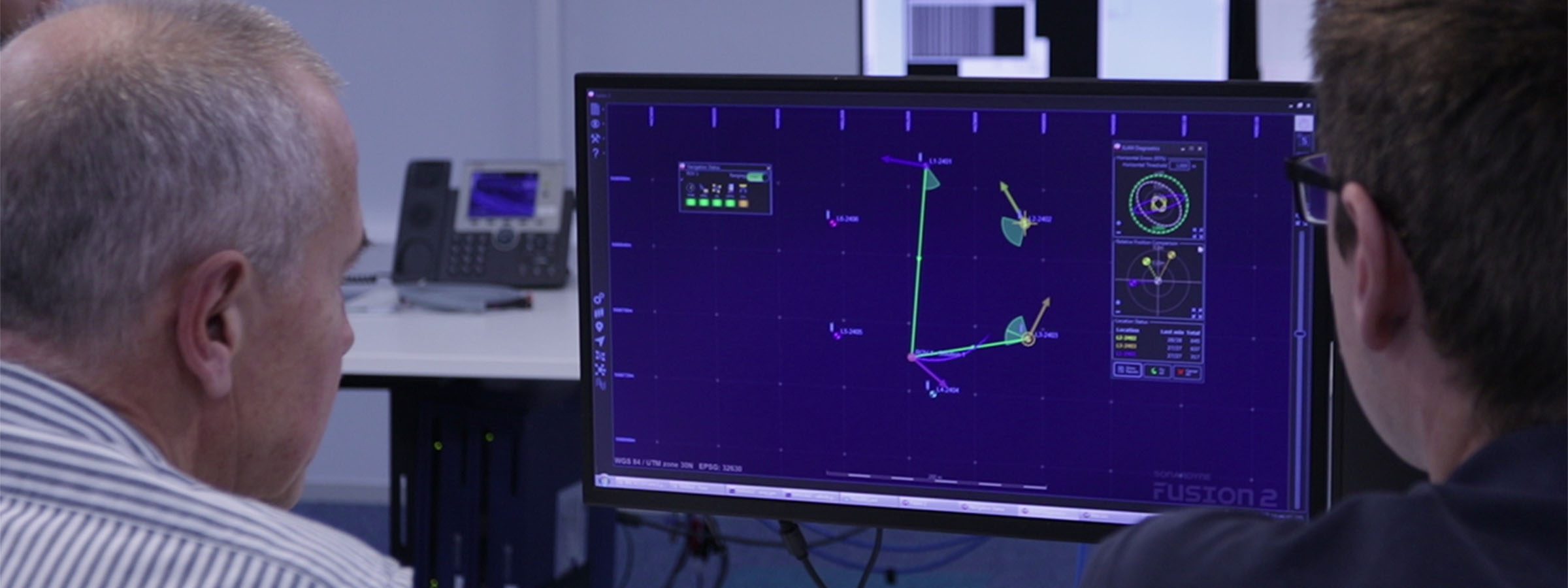

The screen tells you what you need to know, and you don’t need to read raw comms like the guy from the matrix to know what’s happening. You can still keep the comms window open to scare away the client rep if that’s your worry, but with Fusion 2’s advanced command scheduling you’d have to be a machine to read it all now anyway.

Real-time baseline calibration makes it much easier to see where and when things may be going wrong. An incorrect TAT, depth or position will be obvious in a few pings in the data collection, so no more having to deal with the ‘all or nothing’, ‘hit and hope’ feeling you had when postprocessing a data set for the first time, in days gone by. The hour or more playing with the errors in the calibration to get a nice fit, is now all done in minutes. This all allows you to grab a coffee and double check your numbers one more time, enabling you to focus on QC rather than firefighting bad data.

Adjustments can now be made in real time to the confidence values assigned to the position of each and every Compatt transponder, so one Compatt in a difficult location won’t reduce the overall quality of the array. Individual confidence values also mean you can use more types of position sources. For example, lower quality positions can be used to help orientate an array, alongside more accurate SLAM’d, acoustic box-in and published positions, if they are given a suitable error and meet your project specification. As each reference position has a different weighting in the least squares solution, performance isn’t lost in the way it was with the global scale error approach used in Fusion 1 to make difficult arrays fit the ranges.

Also true, is that interfacing to a USBL system for box-ins is now much simpler. Sonardyne and third-party USBLs can now use the same interface, negating the requirement to connect directly to USBL transceivers, and helping to standardise installations across vessels.

It’s true that the box-in itself is now also in real-time, giving the same benefits as already discussed for baselines. And to add to that, box-in collection also has new options for tidal compensation using GNSS height variation and tidal models, to control the corkscrewing of the vessel position as the tide changes as it sails the loop. This source of error could easily account for a 2m shift in typical oceanic conditions. But that just makes you look better, right?

I suppose as the GUI is nice to use, anyone could operate it once it is up and running, with a bit of training, but for those that have a deeper understanding and need to get the best performance from the system, the tools are there to do more than ever before, and faster. If you know how to use them.

Collecting and QC’ing data is often more than just meeting confidence levels, as these only test for random errors. Biased data is much harder to spot after the event. So, let’s not become complacent that this is easy. In customer support we still regularly deal with problems due to incorrect geodesy settings, poor sound speed control, incorrect depth datums and reductions, and pressure depth conversion confusion, so a good understanding and good practices are still as essential for success as ever.