Across a diverse range of marine applications sensors need to be deployed for long periods of time, on the seabed and in the water column. Today’s challenge is getting the data from them in a timely way. Traditional methods of recovering logged data from long-endurance sensors involve using crewed vessels and/or surface buoys. These have major drawbacks in terms of safety, speed, cost and logistics.

Uncrewed surface vehicles (USVs), sometimes also called autonomous or unmanned surface vessels (ASV/USV), now offer a low-risk, cost-effective and cleaner alternative. They eliminate the need to send people out on expensive crewed vessels to conduct what could be a low-logistic data harvesting mission.

The regulatory environment and advances in communications, battery and power management systems, payload sensors and situational awareness, have meant that USVs are now commercially and routinely operating in our water. They’re operating beyond visual line of sight (BVLOS) across a wider range of sectors.

There is a wide range of potential applications for USVs, but here we’ll take you through the options specifically for data collection in both costal locations and offshore waters. We’ll walk you through the key technical and practical considerations for your USV data collection operations; from sensor selection and choosing the most appropriate USV to payload requirements and ensuring data integrity and security.

Just in case you didn’t know, we can support your USV data harvesting operations either by providing hardware to your own USV or through a full turn-key service.

SCOPING YOUR PROJECT

It sounds obvious, but two principal factors drive configuration and operational deployment of a system required to recover subsea data by USV: location and data.

The main considerations associated with location are:

- Distance from land/operating base, which will influence your selection of USV in terms of range and endurance from its operating base.

- Water depth, which affects selection of acoustic frequency. For most applications, a medium frequency (MF 19-34 kHz) is used; however, in deeper depths a lower medium frequency (LMF 14-19.5 kHz) will be required. Sonardyne systems are configured to work in either of these (but not both simultaneously).

- Environmental conditions, which affect both the operating envelope of the USV (principally wave-height) and acoustic efficiency (environmental noise – especially in shallow water). For the latter, it may be that higher specification topside equipment is required, which may consume more of the available power budget from the USV.

Data requirements are driven by how much and how often you want it. The first is obviously driven by the sensor itself, while the latter is usually about how acceptable latency in the retrieved data is. Combined, these determine the amount of time that is required onsite to retrieve the data. However, seabed instrument battery power is also a significant consideration as the wrong logging regime could prematurely drain a battery, not record enough data or impact data quality. More on that later.

Data security also needs to be taken into consideration. Sonardyne instruments, for example, compress the data into a binary unreadable format for transmission through the water column, then data files are encrypted. The encrypted data is either forwarded and decrypted by the user with a security key or it can be decrypted onboard the USV, for real-time analysis by someone who has remote access, before being sent via secure file transfer protocol (FTP) to the end client.

CHOOSING YOUR USV

One of the bigger decisions to make is the type of USV to use. There are now many commercial, off-the-shelf USV platforms available. They vary by size, propulsion system, endurance, payload and met-ocean capability and hull type. But, broadly, they fall into three groups; low power, high power and hybrid.

Low power, environmental energy harvesting

- These are optimised for long-endurance (measured in months) and long-distance (measured in 1,000s of km) , and generate their power from waves and/or solar energy. They have limited power budget available for an acoustic positioning or communications topside, operate at slow speeds and can find it challenging to hold station over a site in strong currents or tidal streams. But they are extremely economic to run. They’re well suited to harvesting data far offshore, where acoustic conditions are good (so smaller and less sophisticated topsides can be used) and when timeliness of data is not critical.

- Typical vehicles: Liquid Robotic’s Wave Glider and Autonaut USVs.

High power, diesel or diesel electric:

- These USVs tend to be larger and faster, but pay for this with more limited endurance of a handful of weeks at most. They have much more power and payload carrying capacity and so are able to support some of the larger and more capable Sonardyne topsides, meaning that they can harvest data in much more challenging acoustic conditions. These characteristics mean that they are highly suited to transits from a shore bae to collect data from sites on the continental shelf, when timeliness of data may also be an issue, including in challenging conditions.

- Typical vehicles: L3 Harris C-Worker class, DriX, Mariner and SEA-KIT.

Hybrid diesel-electric and environmental energy harvesting:

- These USVs use a hybrid power plant to get the best of both worlds (diesel and electric). They use their high power propulsion for high speed ‘sprints’ and supplement this with solar panels, giving them the capability to operate for several weeks. As such, these USVs offer a highly flexible option to either transit to a site at high speed and loiter for an extended period, or to undertake a slower transit to the offshore area and transit between data harvest extraction sites. They have the power and payload to operate a wider range of topsides than low power USVs.

- Typical vehicles: XOCEAN XO-450 and the L3 Harris C-Enduro.

Picking which USV to use will be driven by your concept of operations (CONOPS), but note that this selection will also dictate what topside options are available to you. At Sonardyne we have experience of working directly with the world’s leading USV manufacturers and have learned the pros and cons of each platform. If you already own or operate a USV, we can enable it for seafloor sensor data harvesting, support you and train your team. Alternatively, we can offer you the complete service, taking care of vehicle selection, logistics, offshore operations and secure data delivery.

COLLECTING YOUR DATA – SEAFLOOR INSTRUMENT SELECTION

To retrieve your data, you’ll need communications capability both at the seabed and on your USV. Sonardyne instruments come with embedded communications capability and meet a wide variety of user applications. These range from sophisticated and integrated sensing and measurement instruments, to simple modems that can be interfaced to third party sensors. For detail about the full range underwater sensors that Sonardyne can provide, please get in touch.

At the heart of our instruments and modems is our Sixth Generation (6G) product platform. 6G Wideband spread-spectrum digital signal processing provides reliable and efficient data communications. It’s the ability to operate at long range, with high output power, even in high noise environments, whilst maximising user data through-put and minimising latency or delay. Any acoustic data corrupted is automatically corrected or re-requested, whilst advanced diagnostics support remote understanding of the data and operation of the instrument.

6G currently supports seven telemetry schemes, ranging from 200 to 9,000 bps for a user’s payload. The lower rate schemes are used in more challenging nosier and/or multipath environments. However, given that vessel noise is often one of the most significant limitations on telemetry, USVs can typically take advantage of the higher rate schemes in situations where a large manned vessel might be noise limited.

TOPSIDE

Communication with your chosen seafloor instrument requires a 6G compatible topside system. There are several system configurations available according to the scenario. These topside systems also enable seabed instruments to be checked and reconfigured in-situ (e.g. to alter the logging regime or optimise performance based on changing environmental parameters).

The topside systems all comprise three main components:

- A hull-mounted acoustic transducer or transceiver (capable of underwater target tracking in addition to two-way communication);

- Ancillary sensors: Global Navigation Satellite System (GNSS) and attitude and heading reference systems (AHRS) and,

- An interface to allow access via a remote desktop connection, supported via 4G, Wi-Fi, radio, satellite or executing scripts over short-bust data (SBD).

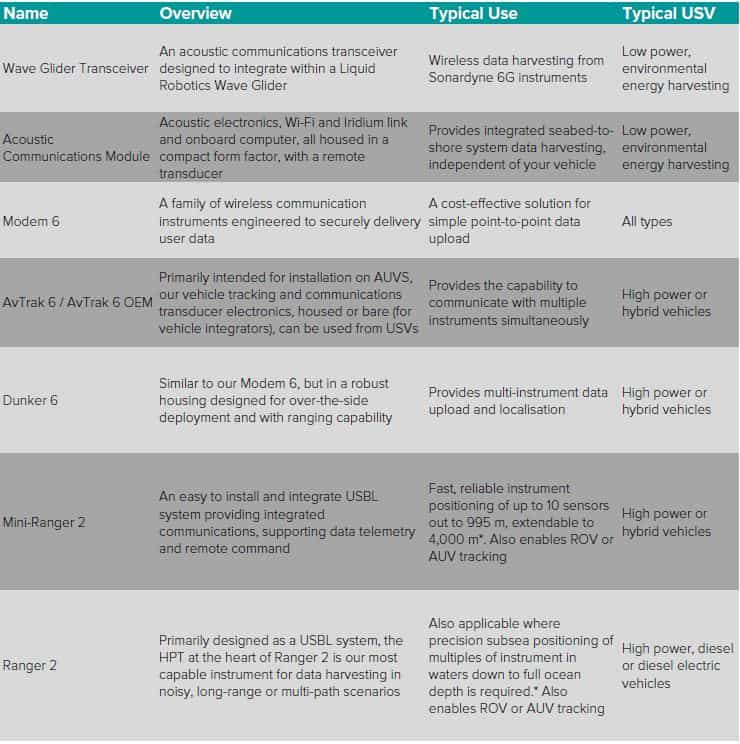

Sonardyne has a range of topside systems applicable to USV data harvesting:

*This will require ancillary equipment such as AHRS or MRU. Contact us for more information.

MANAGING DATA HARVESTING OPERATIONS

Mission planning should incorporate who needs remote access to the vessel systems and how. It should also set out co-ordination between vessel pilots, instrument and acoustic engineers (who will verify and quality control the data as it is gathered before allowing the vessel to move to the next site), and the end customer for the data, to ensure that acquired data is as expected and to confirm any required changes to the sensor’s logging regime or output power.

“While planning is key to ensuring a successful remote data gathering mission, the marine environment is highly dynamic and can present unforeseen challenges.”

To configure and manage data uploads, Sonardyne’s Monitor software application is available. This typically runs on the host platform’s onboard computer or a dedicated machine such as our high specification, Marine Computer. Monitor allows for real-time control, configuration and monitoring of acoustic link quality between instruments and optimal data rates.

We also supply a scripting interface that works through the vehicle’s management system to execute scripting onboard. This enables Sonardyne engineers to run the script through the pilot view interface to download data including auto retry and merging overlapping data records.

Having experienced engineers on hand, to assess signal metrics in real-time, is essential to ensuring successful and optimised data transfer. If a download deteriorates due to, for example, weather, an experienced engineer can make the decision to switch to a lower data rate, which could take longer and use more battery, but would ensure mission success, depending on how much data there is left to upload. This knowledge means that we can offer the ability to resolve and navigate in noisy acoustic environments, such as where there are simultaneous operations, to guide the vessel pilot to a suitable location for optimum data upload, rather than simply increasing the power output of the sensor, which would then impact its battery life.

Experienced engineers, who are familiar with the sensors, their behaviors and the acoustics in different conditions, are also able detect anomalies in, for example, the sound velocity data, or drift in the pressure sensor, or an issue with the logging regime, and either correct the issue there and then or provide a solution, e.g. having detected suspected sensor biofouling or trawl damage.

HARDWARE, SUPPORT AND DATA DELIVERY

Sonardyne is the only company with a full suite of hardware for every requirement as well as a long track record in real-world coastal and offshore data collection, from sensor selection and deployment to delivery of the data. We are also able to conduct sea trials on location or at our dedicated trials facility in Plymouth, to ensure project success.

Our Applications Group has decades of experience in developing and deploying seabed sensors, including array planning. They can lead you and your team through the entire process to ensure you select the right sensors and topside system for your project so that you get the data you need at the level of precision that you require.

We also support many other services using USVs, including: subsea positioning, asset monitoring, acoustic /optical communications, UUV swarm communications, GPS denied environments, ADCP current mapping, LBL box-in, sensor positioning with GPS-A, transition zone seismic operations, ROV tracking, automatic target recognition on pipeline inspection and more.

So, whether you are upgrading your own USV with Sonardyne instruments or you require a full turn-key service, where we supply an end-to-end capability, including USV selection, we are ready to help. Contact us if you would like to learn more.

TRACK RECORD

Task – Seabed deformation monitoring in the North Sea

Date – April 2019, September 2020

Customer – BP

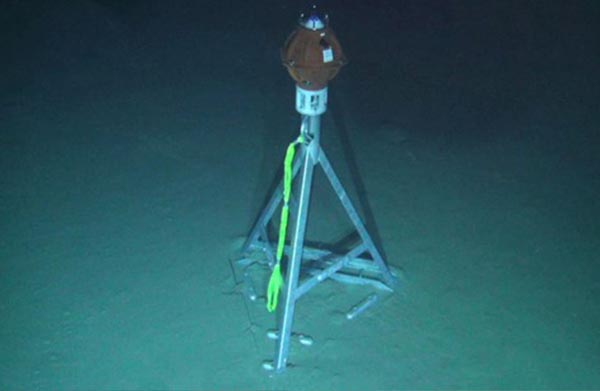

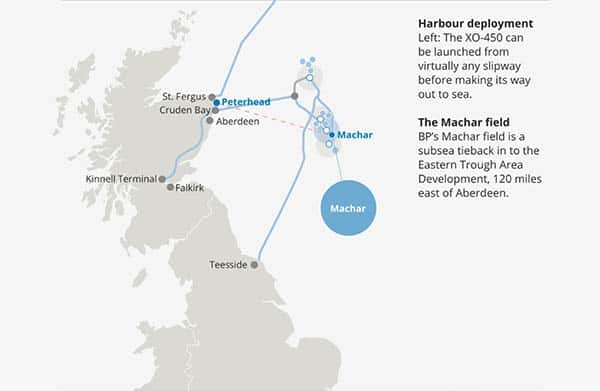

International energy firm BP is monitoring the seabed at its Machar field in the UK North Sea using our Fetch pressure monitoring transponders (PMTs). To harvest the data the four Fetch PMTS are collecting, an XO-450 USV operated by XOCEAN was deployed from Peterhead harbour in Scotland to the field 120 miles out to sea in April 2019 and again in September 2020. In April 2019, the data gathering mission, from the deployment to the return of the XO-450 back at Peterhead, took under 40 hours.

“BP have been pleased with the result of this operation and we have proven the concept of data harvesting with USV. The Fetch units are continuing to monitor the seabed at Machar, which will enable us to continue monitoring the seabed, harvesting data twice a year, using the USV, for some years to come.” – Craig Allinson, Survey and Positioning Lead at BP North Sea.

Find out more here

Task – Seabed deformation monitoring in the North Sea

Date – April 2020

Customer – A/S Norske Shell

A/S Norske Shell is monitoring the seabed at its Ormen Lange field offshore Norway, using our Fetch Pressure Monitoring Transponder (PMT) sensors. Shell contracted Sonardyne directly to use an XOCEAN XO-450 USV to harvest data from an array of 30 Fetch PMTs. During a period of global travel restrictions, the USV was ‘posted’ to Norway on a cargo vessel then handled by a local marine services provider in Stavanger. It carried out the full data harvesting mission over just three days, traveling 300 km in total and saving an estimated 5.4 tonnes of CO2 emissions per day, compared with a manned vessel.

The array has since been extended and a further two data harvesting operations successfully carried out.

Read more here

Task – Subduction zone monitoring

Date – 2017

Customer – Geomar

Geomar Helmholtz Centre for Ocean Research in Kiel has been studying some of the globe’s most tectonically active areas by way of long endurance monitoring. Using our Autonomous Monitoring Transponders (AMTs) they created a monitoring array, the Geodetic Earthquake Observatory on the SEAfloor (GeoSEA) project, in 2,800-5,400 m water depth, offshore northern Chile on the Nazca-South American plate boundary. Data from the array was recovered by a US research ship using a Sonardyne HPT 7000 dunking modem deployed over the side, as well as GEOMAR’s GeoSURF Wave Glider, equipped with a 6G acoustic communication module fitted in its hull.

Read a more in-depth report here